0040506004 0919

Page 2-37

Operating and installation instructions

Thrust actuator ARI-PACO

®

2G 1,6D/Y

9.2 ARI-PACO

®

2G 1,6Y

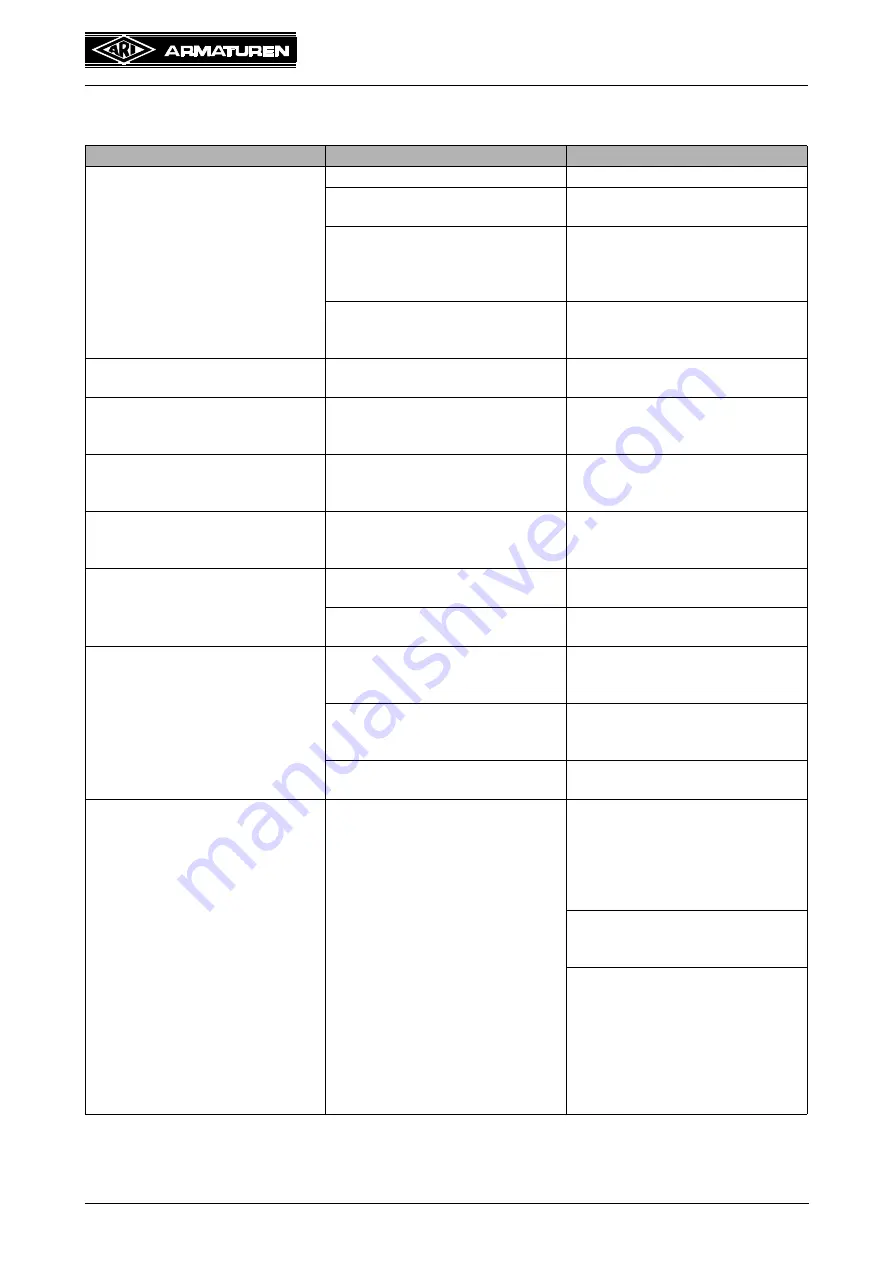

Fault

Possible Causes

Remedy

Green LED does not lit

Power failure

Check the mains power supply

Operating voltage is incorrect

Connect the operating voltage

indicated on the rating plate

Elektronics have burnt out

Make sure the mains voltage

coincides with the value indicated

on the rating plate. Replace the

electronics.

Terminal not connected correctly

or cable does not make proper

contact inside terminal

Insert the terminal securely and

check the connecting cable

Actuator starts briefly, then stops

and starts again briefly

CDF management is active due

to internal overheating

Protect against radiated heat, lag

the pipes

Actuator stops for 45 s or does

not respond to control signals for

45 s

Actuator has detected a

handwheel movement

The motor is not started for

another 45 s for safety reasons

Initialization cancelled; red and

yellow LEDs lit

Outside the valid travel range

Possible causes: Incorrect fitting

projection, incorrect column

length, valve missing

Red LED lit

Actuator not initialized yet.

Start an initialization run after

mounting the actuator on a valve

and connecting the control signal

No values or incorrect values at

analogue output

Parameter settings are incorrect

Set the parameters as described

in 5.5.2.3 Switch functions

Analogue output card missing or

defective

Replace the analogue output

card

Actuator oscillates continuously

about a point

Proportional action Xp setting on

controller is too low

Increase the Xp value (refer to

the controller Operating

Instructions)

Dead band setting on controller is

too low

Increase the dead band value

(refer to the controller Operating

Instructions)

Dirty slide

Clean surface with Greycode

(black/white)

Actuator cannot be controlled

with analogue control signal

Actuator is set to 3-point

operation or is currently

controlled by a 3-point signal

(indicated by lit LED above

3-point connector)

By withdrawing the connector for

the 3-point signal, you can

determine whether the actuator is

set to 3-point operation or

whether it is simply being

controlled by a 3-point signal

If the LED goes out, a 3-point

signal is present, e.g. from an

anti-freezing contact

If the LED is still lit, the actuator is

set to 3-point operation. An

analogue control signal must be

present during the initialization

run in order to control the

actuator with an analogue signal!

Repeat the initialization with an

analogue control signal applied