43

5. Inspect the bearing dowel pins for wear.

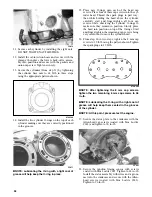

6. Inspect the sealing surfaces of the crankcase

halves for trueness by placing each crankcase half

on the surface plate covered with #400 grit wet-or-

dry sandpaper. Using light pressure, move each

half in a figure eight motion. Inspect the sealing

surfaces for any indication of high spots. A high

spot can be noted by a bright metallic finish. Cor-

rect any high spots by continuing to move the half

in a figure eight motion until a uniform bright

metallic finish is attained.

NOTE: Care must be taken not to remove an

excessive amount of aluminum, or the crankcase

must be replaced. If excessive aluminum is

removed, too much pre-load will be exerted on the

crankshaft bearings when assembled.

CM160

Crankshaft

NOTE: If any servicing of the connecting rods,

center bearings, or oil-injection pump drive gear is

necessary, Arctic Cat recommends that the crank-

shaft be taken to a qualified machine shop for that

service.

1. Wash the crankshaft with bearings in parts-clean-

ing solvent.

2. Inspect the bearings for wear, scoring, scuffing,

damage, or discoloration. Rotate the bearings.

Bearings must rotate freely and must not bind or

feel rough. If any abnormal condition is noted,

replace the bearing.

FC039

3. Inspect the connecting-rod bearings by rotating

them. The bearings must rotate freely and must not

bind or feel rough. If a connecting-rod bearing

must be replaced, the connecting rod and crank pin

must also be replaced.

FC040

4. Inspect the oil-injection pump drive gear for any

signs of worn or chipped teeth. If either condition

exists, replace the gear.

NOTE: Lubricate bearings thoroughly prior to

assembly.

Removing/installing Outer

Crankshaft Bearings

NOTE: The end bearings are not pressed onto

the crankshaft. The bearings can be removed sim-

ply by sliding them off the crankshaft.

CM161

Inspect the crankshaft bearing area for wear. If any

wear is noted on either end, replace the crankshaft end.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.

Summary of Contents for 500 Sno Pro

Page 1: ...TM SHARE OUR PASSION Operator s Performance Manual Performance Manual 500 Sno Pro...

Page 2: ......

Page 6: ...NOTES...

Page 22: ...16 NOTES...

Page 68: ...62 NOTES...

Page 92: ...86 NOTES...

Page 93: ...87 NOTES...

Page 94: ...88 NOTES...

Page 95: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2258 721...