14

7.3

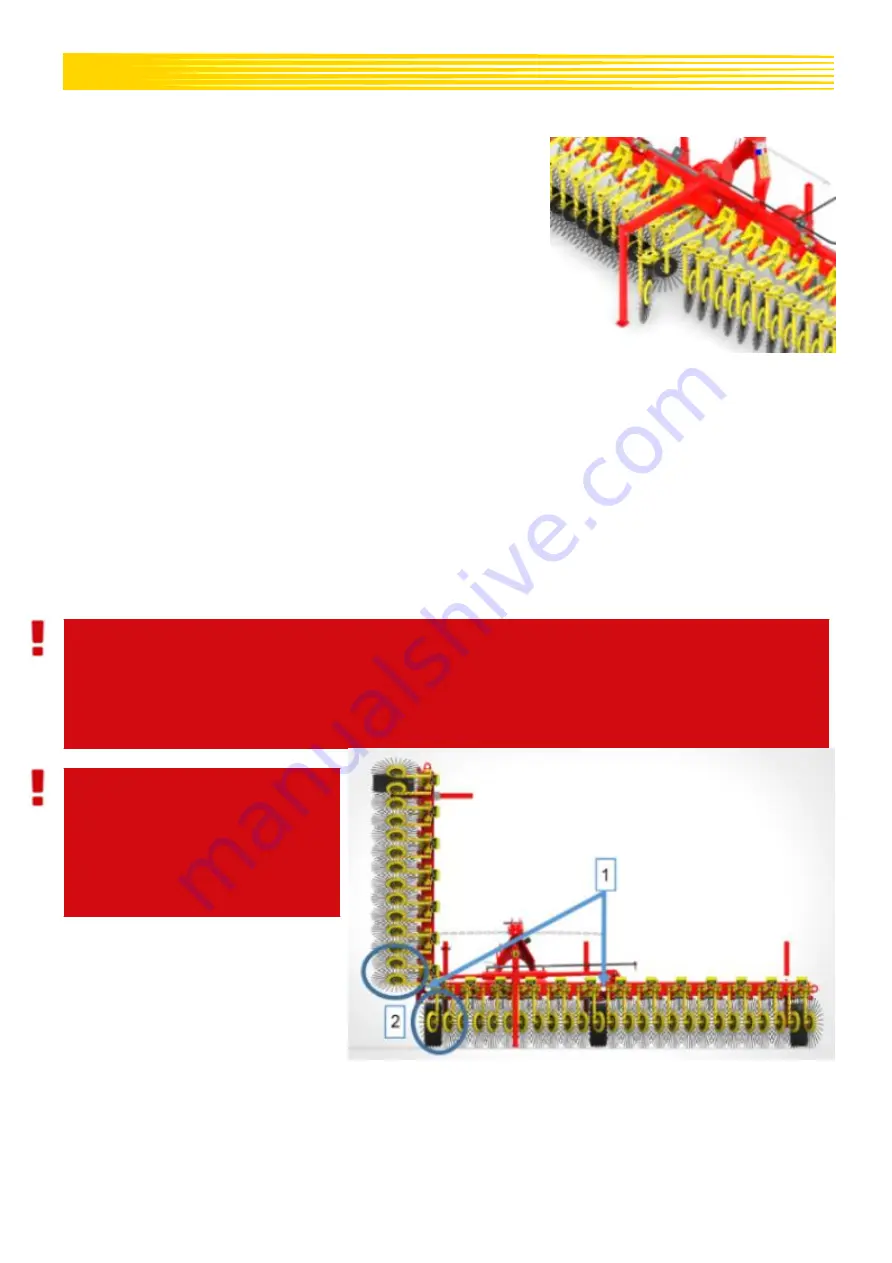

SAFE PARKING

To ensure safe parking of the implement, lower the parking

support and the two feeler wheels on the center frame, as shown

in Figure 3.

Figure 3

7.4

TEST FOLDING

Connect the hydraulic lines to the towing vehicle, and ensure that the connections are clean to prevent

contamination in the oil.

Actuate the control unit to fill the cylinder with oil. The cylinder is filled as soon as the securing chains are

offloaded. Unhook the securing chains and hook them in on the other end of the chain. Ensure that no one

is in the danger zone and only fold the implement when it is lifted off of the ground.

The implement must also be lifted off of the ground when it is folded into transport position. Do not forget

to hook-in the securing chains and close the stop tap.

When uncoupling the implement, you must offload the hydraulic hose through the float position before

pulling it out.

CAUTION!

Before unfolding the machine, always ensure that the securing chain is unhooked. If the

implement is unfolded with the securing chain hooked in, the machine can be irreversibly

damaged or the securing chain and its direct components can at least be initially damaged, which

can result in failure when the chain is later loaded to capacity. Consequently, the securing chain

must always be replaced after a faulty / incorrect folding procedure!

CAUTION!

Before folding the implement, the

four arms left and right of the

pivot point must be in working

position. Risk of collision with

the arms when they are folded

up!

Figure 4

1:

Pivot point of the folding

2:

These 2 + 2 arms must ALWAYS be in working position before

they are folded up!

Summary of Contents for RH 600 M1

Page 30: ...30 NOTES...

Page 31: ...31 NOTES...