INSTALLATION

Before installing the detection and actuation system, the System

Planning portion of this manual should have been reviewed for

particular application resulting in a system layout sketch. Always

read the procedure before installing each component to become

familiar with the correct installation steps as they apply to the

particular application and sketch.

NOTICE

For ease of installation, the fire suppression

system should be installed before the detection

and actuation system.

INSTALLATION MATERIALS

All hardware and tools should be on hand before beginning the

installation. Check the Component Index, Page 37, to make

certain all necessary system components are available.

Material to be supplied by the installer includes:

– Ample cable ties or 1/4 in. (6 mm) clamps to guide and support

the detection wire.

– Non-wire braid hose (1/4 in.) to be used as a protective cover-

ing for the detection or power wire at points of securement and

when passing through bulkheads.

– Actuation line (1/4 in. hydraulic hose) and fittings to connect the

electric detection and actuation system actuator to the fire

suppression system. (See applicable ANSUL Fire Suppression

Systems installation manual for additional details.)

Tools required to perform the installation include:

– Drill and Drill Bit Set (or welding equipment)

– 1/8 in. Blade Screwdriver

– 1/4 in. Blade Screwdriver

– Phillips Screwdriver

– Standard Sidecutters

– Small Sidecutters (1/4 in. cut)

– Wire Stripper

– Low Wattage Soldering Pencil (35 watt)

– Rosin Core Solder (60/40)

– Rubberized Electricianʼs Tape

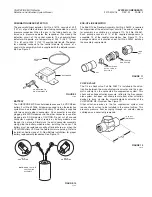

MOUNTING BRACKET INSTALLATION

Three mounting bracket options are available:

• Mounting control module and pneumatic actuator on same

bracket

• Separate brackets for control module and pneumatic actuator

• Control module retrofit bracket to existing CHECKFIRE MP

bracket

Bolting

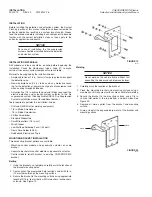

1. Using the bracket as a template, carefully mark the location of

the bracket mounting holes.

2. Center punch the premarked hole locations and drill 3/8 in.

(10 mm) holes through the mounting surface.

3. Secure the bracket to the mounting surface using appropriate

length of 5/16 in. (8 mm) bolts with flat washers, lockwashers,

and nuts. See Figure 19.

FIGURE 19

002761

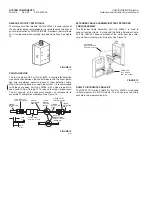

Welding

NOTICE

Never weld on the vehicle frame without first

consulting the owner and vehicle manufacturer.

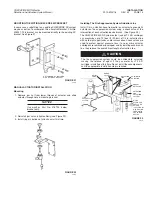

1. Carefully mark the location of the bracket.

2. Clean the mounting bracket and mounting surface using a

wire brush until clean steel surfaces are available for welding.

3. Secure the bracket to the mounting surface using 1/8 in.

(3 mm) fillet welds at the top, bottom, and both sides. See

Figure 20.

4. Remove all weld spatter from the bracket and mounting

surface.

5. Prime and paint the exposed bare metal of the bracket and

mounting surface.

FIGURE 20

002762

INSTALLATION

PAGE 12

REV. 02 2012-MAY-18

CHECKFIRE MP-N Electric

Detection and Actuation System Manual

WELD

WELD