CONTROL MODULE WIRING/DETECTION WIRE ROUTING

(Continued)

Wiring (Continued)

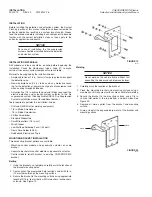

2. Route the detection wire through a strain relief at the bottom

of the MP-N control module, to the terminal strip in the control

module. Make certain wire is not exposed to damage. See

Figure 27.

3. On the terminal block at the control module, install the wires to

terminals No. 3 and 4. See Figure 27.

Note:

It is not necessary

to be concerned about polarity when installing these wires.

FIGURE 27

002765

Thermal Detector Installation

When installing the ANSUL spot detectors, use only components

approved by ANSUL. These components consist of the following:

– Mounting Bracket Shipping Assembly, Part No. 416221 –

Consists of one mounting bracket.

– Detector Clamp Package Shipping Assembly, Part No. 416214

(for use with protective tubing) – Consists of (2) cable clamps,

(2) 1/4-20 x 1/2 in. socket head screws, (4) flatwashers,

(2) spacers, and (2) 1/4-20 x 5/8 in. socket head screws.

– Detector Clamp Package Shipping Assembly, Part No. 416762

(for use without protective tubing) – Consists of (2) cable

clamps, (2) 1/4-20 x 1/2 in. socket head screws, (4) flatwashers,

and (2) 1/4-20 x 5/8 in. socket head screws.

– Detector Connector Package Shipping Assembly, Part No.

416213 – Consists of (2) connector housings, (6) pins, and

(2) heat shrinkable sleeves.

– Protective Tubing Shipping Assembly, Part No. 416215 –

Consists of 100 ft (30.5 m) of tubing.

– Multi-Conductor Cable, Part No. 417055 – Cable must be

purchased by installer and must have a temperature rating of

392 °F (220 °C) minimum, 16-18 gauge, two conductor with

drain, minimum O.D. of 0.230 in. (5.8 mm).

– AMP crimping tool, Part No. 416784.

To properly install the thermal detector, complete the following:

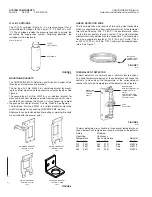

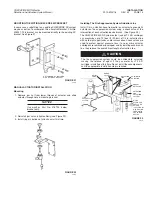

1. Secure the mounting bracket(s) near the hazard. Make certain

the bracket does not shield the detector from the heat or

flame.

2. Attach the correct temperature range spot detector to the

bracket using (2) two flatwashers and (2) two 1/4-20 x 5/8 in.

socket head screws supplied in detector clamp package. See

Figure 28.

FIGURE 28

000875

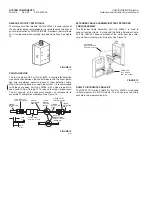

3. Starting at the ANSUL CHECKFIRE Control Module, measure

and route the cable to the first detector.

Note:

If protective

tubing is to be used, make certain cable is run through it

between each detector.

4. The circuit cable is 3 conductor. It consists of two insulated

wires and one bare ground wire. Cut all wires equal in length

and strip the outer jacket and inner sheath back 1 1/4 in.

(32 mm).

Note:

Make certain not to cut into the insulation on

the two insulated wires or cut into the bare ground wire. See

Figure 28.

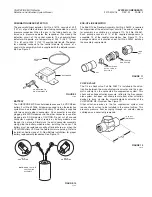

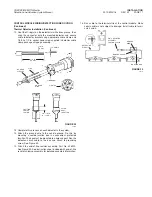

5. With the outer jacket and sheath cut back, strip the insulation

on the two inner wires 1/4 in. (6 mm). See Figure 29.

6. Slide the rubber sleeves from the AMP connector over the 3

wires. The small end of the sleeves must be toward the striped

end of the wires. See Figure 29.

7. Slide a piece of heat shrinkable tubing onto the cable. See

Figure 29.

8. Crimp the pins onto all three wires, using AMP crimping tool,

AMP part No. 90277-1. See Figure 29. This tool is required for

proper crimping. It can be purchased through your local elec-

tronics distributor or is available through ANSUL as Part No.

416784.

9. Press the pins into the connector housing. The two insulated

wires go into holes 2 and 3 and the bare ground wire goes into

hole 1. Make certain each locks into place. The bare ground

wire must go into hole 1 but it makes no difference which of

the two insulated wires goes into hole 2 or 3. See Figure 29.

10. Press the rubber sleeves into the connector holes.

11. Fit the heat shrinkable tubing over the connector so it covers

approximately 3/8 in. to 1/2 in. (9 mm to 13 mm) of the

connector. Heat the tubing with an approved heat gun, shrink-

ing the tubing onto the connector and cable to form a tight,

waterproof fit. See Figure 29.

INSTALLATION

PAGE 16

REV. 02 2012-MAY-18

CHECKFIRE MP-N Electric

Detection and Actuation System Manual

CABLE

CLAMP

PROTECTIVE

SLEEVE

SHRINK

TUBING

1/4-20 x 1/2 IN.

SOCKET HEAD

SCREW

1/4-20 x 5/8 IN.

SOCKET HEAD

SCREW (2)

MOUNTING

BRACKET

SPOT

DETECTOR

RUBBER

SLEEVES

PINS

DETECTION

CIRCUIT

3 4