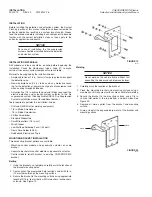

MOUNTING THE CONTROL MODULE

The CHECKFIRE MP-N Control Module can be mounted to either

a flat, rigid surface or utilizing one of the three bracket options.

If mounting the control module to a flat, rigid surface, use the

appropriate fasteners.

If mounting the control module to the MP-N bracket, complete the

following steps:

1. With the bracket securely mounted, position the holes in the

control module mounting flanges over the threaded studs on

the bracket. Using the supplied mounting hardware, securely

fasten the control module to the bracket with four lock

washers and nuts.

2. If utilizing the MP retrofit bracket, first fasten the retrofit

bracket onto the existing MP bracket by using the supplied

fasteners. With the MP retrofit bracket securely fastened,

position the holes in the control module mounting flanges over

the threaded studs and securely fasten.

Remove the cover from the control module.

If the internal 3.6

VDC battery is in place, disconnect the wire plug until the

field wiring is complete.

If the strain relief(s) and plug(s) are not in place, coat the male

threads with Dow Corning 737 RTV Sealant or equal and install in

holes of module back box.

At this point, the external field wiring can be installed.

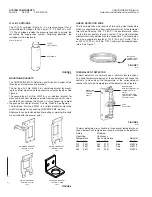

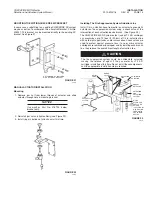

GAS MOTOR ACTUATOR ASSEMBLY

Mounting

1. The gas motor must be mounted in a location where it will not

be subjected to damage or corrosion.

2. The gas motor can be mounting in either the horizontal or

vertical position.

3. It must be mounted within 10 ft (3.1 m) linear cable length of

the CHECKFIRE Control Module.

NOTICE

After automatic system actuation, the

internal gas motor device must be

replaced. Make certain assembly is

mounted in an accessible location.

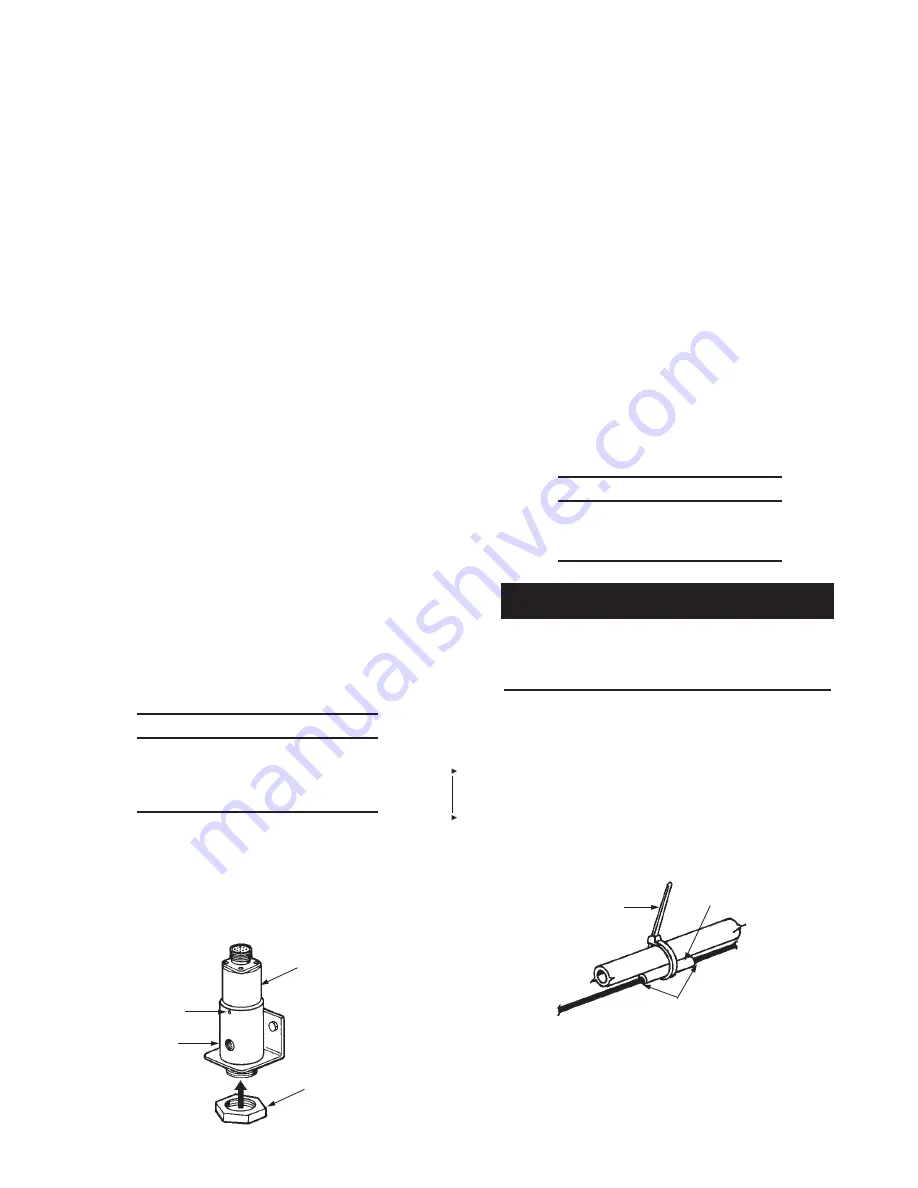

4. Securely mount the actuator bracket, Part No. 54923, either

by welding or bolting to a rigid surface.

5. Remove locknut from gas motor body, position body in

bracket hole and reinstall locknut. Wrench tighten. See Figure

24.

Note: For proper installation, make certain the gas

motor is threaded fully, 6 threads, onto the actuator body

and properly secured with the allen head set screw.

FIGURE 24

003925

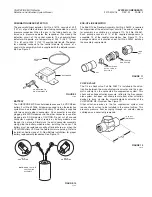

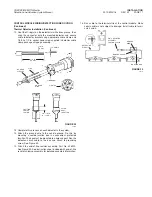

CONTROL MODULE WIRING/DETECTION WIRE ROUTING

Mounting

1. Using the system layout sketch, investigate each point where

the wire will be secured to the vehicle. Keep in mind all the

guidelines in the System Planning Section. Do this on a

vehicle that has been operated recently to avoid securing the

wire too close to extremely hot components.

2. After the vehicle has cooled, loosely route the wire from the

start of the hazard throughout the proposed path through the

hazard areas. If splicing is required, see Splicing, Page 16, for

detailed information.

3. Secure the detection wire by completing the following steps:

See Figure 25.

a. Start at the beginning of the detection wire leading into the

hazard area. Secure the detection wire every 12 to 18 in.

(30 to 45 cm) using black nylon cable ties, Part No. 56691,

and protective coverings, Part No. 56692, at points of

securement. Secure more often if necessary. Attach the

wire to mounting surfaces, decks, struts, etc., always

keeping System Planning guidelines in mind.

NOTICE

The minimum bend radius for detection

wire must not be less than 2 1/2 in. (64

mm).

Detection wire must never be routed through a hole or

near sharp edges without being properly protected.

Failure to protect the wire from being cut or abraded

could cause it to short, causing a false discharge.

b. Secure the wire at least once immediately before it passes

through a hole in a vertical or horizontal surface. At the

hole, a 1/4 in. (6 mm) rubber sleeve, Part No. 56692, or a

special grommet to fit the hole should be used to protect

the wire from wear due to vibration. If the rubber sleeve

might slide from under the cable tie and off the wire, tape

the rubber sleeve to the wire using electricianʼs tape to

keep it from sliding (see Figure 25). This hose protection

should also be used at locations where the wire would rub

against other hard surfaces, rough edges, or sharp

corners.

FIGURE 25

000872

!

CAUTION

INSTALLATION

PAGE 14

REV. 02 2012-MAY-18

CHECKFIRE MP-N Electric

Detection and Actuation System Manual

LOCK

NUT

GAS

MOTOR

SET

SCREW

ACTUATOR

BODY

CABLE TIE

1/4 IN.

RUBBER SLEEVE

TAPE AT

BOTH ENDS