17

Vessel selection according to

SKWI 93-1

It must be possible for the ex-

pansion vessel to take in at least

the calculated volume

Vnom

(given in litres).

The typical intake volumes of

the individual tank sizes can be

read directly from

table

2

and

thus the suitable tank can be de-

termined. When making the se-

lection, it must be ensured that

the system's values for

Hp

and

Pact

respectively are within the

threshold values in the table

.

Other threshold values are pos-

sible. Generally, Boyle-Mari-

otte's gas law applies. This is

based on the premise that the

product of volume and pressure

in the pressure tank is to remain

constant in all operational situa-

tions. As Pneumatex tanks have

no volume-restricting fittings,

the gas law can be applied for

the tank, in the form

Vs ∙ Pt =

Ve∙ Pe

for all special cases, un-

til the maximum construction

pressure (Pcons = 6 bar) has

been reached. Here, the follow-

ing applies:

Vs = system volume of the tankwhen

empty on the water side.

Ptank = pre charge pressure at the

tank (P absolute value).

Ve = final volume of air content, i.e.

difference between total tank vol-

ume and water volume taken in.

Pe =

final pressure in tank, which aris-

es if the volume Ve is reached (P

absolute value).

In all cases, the applicable official

regulations must be adhered to!

Expansion vessel calculation

Calculation

For correct dimensioning of an

expansion vessel, the following

system data must be known:

-

Total system content VS,

(i.e. the

sum of the content of any stor-

age tanks, pipes, radiators, etc.

in the solar system).

-

Maximum supply tempera-

ture tsupply

for the heating

system's dimensioning condi-

tions.

-

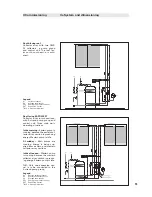

System's static height Hp,

i.e.

height from the centre of the

tank to the system's highest

bleed point

(cf. fig.).

For systems with a maximum

supply temperature above boil-

ing point at atmospheric pres-

sure, the saturation pressure

at the relevant system compo-

nent is to be taken into account

as well as the static height.

-

Construction pressure Pcons

of the most important system

components, which must be

greater than or equal to the

safety valve's

activation pres-

sure Pact

whereby any static

height differences must be

taken into account.

-

Expansion volume Vnom

This is to be calculated accord-

ing to the formula:

Vnom

=

VS

∙F∙x (litres).

V S

= total system content in litres

when cold

F = thermal expansion factor

according to tavg

(see tab. 1)

x = safety margin factor

x = 3; up to 30kW nominal

power

x = 2; 30 to 150kW

nominal

power

x = 1.5; over 150kW

nominal

power

Example calculation: page 20/21

!

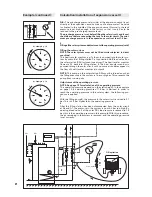

II Commissioning

IIc Expansion vessel

Intrinsically safe system, see also next page

Thermal expansion factor F

tavg = 30 °C 40 °C 50 °C 60 °C 70 °C 80 °C 90 °C 100°C 110°C

F =

0.004 0.008 0.012 0.017 0.022 0.029 0.035 0.043 0.051

Assumed filling temperature 10°C = t1

Tsupply = supply temperature °C

Treturn = return temperature °C

tavg = average water temperature in the system =

t

treturn

2

min. required pre charge pressure in tank = Hp + 0.5 bar

min. required activation pressure SV Pact = Pwork + A - B

normal working pressure (Pwork) =

Pact

1.3

EXT

= expansion vessel

SV1

= safety valve