2

Contents

0 Data

OWR 20 data

Notes

3

General planning notes

4

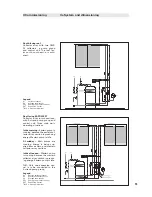

I Installation

Ia Tiled roofs

5

Ib Flat roofs

10

II Commissioning

IIa System and dimensioning

- South and east/west systems

14

- OWR 20 dimensioning

15

IIb Hydraulic connections

16

IIc Expansion vessel

- Expansion vessel calculation

17

- Intrinsically safe solar system

18

- Example: expansion vessel calculation

20

IId Protective devices

- Lightning protection

22

- Scald protection

22

- Overheating protection

22

- Safety valve

22

IIe Maintenance/Repair

23

Quic

k mounting guide f

or installation personnel:

Pa

g

e

The solar collect

or syst

em is t

o be installed b

y qualified personnel only

.

Pac

kaging

+ T

ranspor

t:

3

Store collector

s cor

rectly; don

’t throw the pac

kaged bo

xes.

Transpor

t collector

s in pac

kaging only

.

Collector mounting:

T

iled roof

5-9

W

ork preparations as shown on page 5-8, assembly as shown on page 8-9.

Flat roof

10-1

3

W

ork preparations as shown on page 1

0-1

1, assembly as shown on page 1

2-1

3.

Collector connections

to a collector field:

Compensator

s and

8/9/1

2

The screw connections of the compensator

s are to be tightened with a tightening torque of max. 1

5 Nm.

U-pipes/Blind caps

8/9/1

2

The included high temperature flat g

ask

ets must be used.

S

ensor placement

in the collector field:

S

ensor

9/1

3

The collector sensor must be inser

ted into the sensor well all the w

ay (1

8-1

9 cm) at the solar liquid outlet

(flow).

The sensor cable must be fixed to av

oid shif

ting (e.g. snow load, animals).

Connecting the solar pipes with

the solar collector field

S

olar pipes

9/1

3

At

tention is to be paid to the male connector

s, shown in the pictures on page 9/1

3.

The connection labeled

„hot“ is the flow

. The connections must not be confused.

Expansion vessel

The cor

rect connection of the expansion vessel is determined by the site management.

The pre c

harge

pressure must be adjusted before the filling of the system.

Expansion vessel pre c

harge pressure = Ok collector up to middle of expansion vessel in bar + 0.5 bar

,

but at least at 1

.0 bar

P

ressure test

Af

ter the mounting of the collector field, solar pipes, pump groups and the heat consumer

s the system

must be c

hec

ked for absolute leakproofness (e.g. compressed air at 2-3 bar for at least 2-3 hr

s.),

or with fluid (e.g. 4 bar for at least 2-3 hr

s.)

Filling of the solar system

resp.

21 16

Connect filling station to

A

O +

A1

. Fill system slowly

. The bleed valve at the pump station is closed.

R

emo

ve flow meter

.

Do not fill in dir

ect sunshine!

Flushing the system

resp.

21 16

The flushing cleans the system and bleeds the whole facility

.

This flushing is to be done thoroughly and

without inter

ruption.

S

olar controller:

The controller set

tings are to be set by the site management. Chec

king of the cor

rect electric connections.

Commissioning:

Af

ter initial star

t-up an acceptance testing protocol is to be completed, dated and signed by the installer

and by the operator

. This document belongs to the operator of the facility

.

IMPOR

TANT

:

Don't use an

y zinced components in the solar cir

cuit!

Tyf

ocor LS is a complet

e mixt

ur

e.

Don't mix with w

at

er!