12

17

18

16

19

20

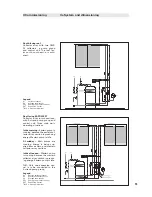

The final step is to fasten the

pivot bolts at the lower end of

the supports. The standing sup-

ports are pre-configured in the

factory for approximately 40°.

The collector can be mounted at

a more shallow angle by moving

the lower end inwards. Moving

the upper end inwards makes

the angle steeper. The supports

can also be cut to length in

order to achieve an even more

shallow angle.

The central connecting expan-

sion joint is to be screwed tight

on one side. Hydraulic connec-

tions: see page 18

Another support is to be di-

mensioned for installation of

the second collector. Follow the

same procedure as for the first

collector.

The central connecting expan-

sion joint is to be tightened us-

ing two spanners diametrically

opposed.

The other two expansion joints

are also to be installed. Dur-

ing insertion, it is necessary to

squeeze the expansion joints

together a little.

Screw the U-bend in place. With

the blind cover, all connections

are now sealed (torque max. 15

Nm).

The sensor is to be inserted on

the collector's input and output

side. Pierce the rubber plug, for

example with a 5mm drill bit.

The rubber plug is to be com-

pletely pulled out, in order to

make sure that the sensor is

inserted into the sensor well.

The sensor is then to be inserted

together with the plug.

21

22

23

24

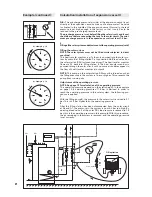

Warning!

Please observe the hydraulic

connection variants on page 16.

In the following steps, the in-

stallation of expansion joints is

described for the case where

the unit is connected accord-

ing to the Tichelmann principle

(see page 16, diagram A or B).

The collectors can also be con-

nected conventionally on one

side (see page 16, diagram C)

or conventionally on alternating

sides from the left or from the

right (see page 16, diagram D).

Only the lower connections are

required here (see page 16).

We recommend connection ac-

cording to the Tichelmann prin-

ciple (see page 16, diagram A

or B).