18

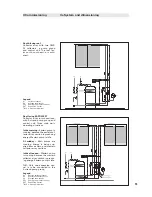

The dimensioning of the expan-

sion vessel in the collector cir-

cuit must be such that, even af-

ter an interruption to the power

supply of the circulation pump

in the collector circuit during

the time of maximum solar irra-

diation intensity, operation can

be automatically resumed once

the power supply is restored,

and once the liquid in the collec-

tor has condensed again.

If the heat transfer medium can

vaporise in conditions of stagna-

tion, the expansion vessel must

be installed in such a manner

that upon stagnation, fluid is

forced out of the collector, but

no steam.

Note

If it is possible for the heat trans-

fer medium to vaporise in condi-

tions of stagnation, this entails a

specific dimensioning rule!

In addition to the usual dimen-

sioning for closed space-heat-

ing systems (expansion of the

entire heat transfer medium),

the expansion vessel must be

able to compensate for a vol-

ume which corresponds to the

total volume of the heat transfer

medium in the collector group

and all connecting pipes be-

tween the collectors, plus an

additional 10%.

It must be ensured that damage

to the expansion vessel cannot

Intrinsically safe solar system

be caused by the hot heat trans-

fer medium. In particular, the

daily temperature cycle which

arises during normal system

operation must not cause the

hot heat transfer medium to

reach the expansion vessel.

The expansion vessel must be

installed in the cold section of

the collector circuit, i.e. in the

part of the collector circuit where

the heat transfer fluid flows from

the storage tank to the collector.

In cases of doubt, it is neces-

sary to install a suitable cooling

line, e.g. coiled pipe or cooling

vessel, in front of the expansion

vessel.

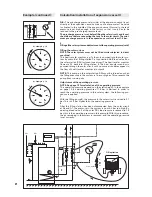

Automatic bleed valves

We do not recommend automatic bleed valves! If, however, there is

no alternative, automatic bleed valves must always be installed verti-

cally. It is only permissible to install automatic bleed valves or similar

systems if a tight-sealing manual shut-off valve (e.g. ball valve) is

situated immediately ahead of each one.

After automatic bleeding of the system, the tight-sealing shut-off

valve must be closed manually, and remain closed. Only fittings

which are suitably temperature-resistant and pressure-resistant may

be installed, see p. 20, 6 bar.

!

The expansion vessel con only

be connected to the AMK col-

lectra ag pumps group, if it is a

tank with an integrated smooth

bore heat exchanger, chiefly a

hot water generator. When fill-

ing the tank through a plate

heat exchanger, a tank for cool-

ing off must be installed before

the expansion vessel.

In solar circuits with more than

one reservoir tank the expan-

sion vessel connection must al-

ways be made to the reservoir

tank with the lowest medium

Connecting the expansion vessel

temperature. The connection is

to be made at the outlet side

of the smooth bore heat ex-

changer (return flow solar-side),

although before any motor

switching valves, motor globe

valves or pumps groups (in flow

direction).

Solar systems with AMK col-

lectra ag vacuum tube collec-

tors must be completely bled.

At the upper connection to a

plate heat exchanger a heat-re-

sistant manual deaerator must

be installed. Depending on the

type of connection to the cool-

ing-off tank for the expansion

vessel a deaerator may need to

Bleeding

be installed there also. Manual

deaerators should be included

directly at the connection of the

smooth bore heat exchanger to

the reservoir tank.