22

American Dryer Corp.

450370 - 2

NOTE:

Fuse 1 is for computer power rated at 1/2-amp. If

fuse blows, it is a computer board fault. Fuse 2 is for 24V

control power rated at 5-amp. If fuse blows, it is a 24V

control fault.

S.A.F.E. System Theory of Operation

While the dryer is in an idle state or 20-seconds after the heat

turns off, the Phase 7 control monitors the S.A.F.E. system

probe located in the top of the tumbler chamber and records

the minimum temperature. If the minimum recorded S.A.F.E.

system probe temperature is no less than 120° F (48° C) and

the control detects a 50° rise in temperature, this will be the

trip point and the S.A.F.E. system routine will activate.

While a drying cycle is in process and the heat has turned on

at least once, the Phase 7 control monitors the exhaust

temperature transducer. If the drying cycle temperature set

point is set greater than 160° F (71° C) and the control detects

an exhaust temperature rise 25° F greater than set point, this

will be the trip point and the S.A.F.E. system routine will activate.

If set point is below 160° F (71° C) the trip point will be 185° F

(85° C).

Once the S.A.F.E. system routine is activated, water will be

injected into the tumbler chamber. Anytime water is being

injected into the tumbler; the tumbler drive will turn the load for

1-second every 15-seconds. This process will continue for a

minimum of 2 minutes. After 2 minutes has elapsed, the control

will check if the temperature remained above trip point, if so

water will remain on. The control will continue to check if

temperature is above trip point every 30-seconds. If the water

has been on for a constant 10 minutes, the water will be turned

off regardless of the temperature. If the temperature has

dropped below trip point, the control will turn off the water prior

to 10 minutes.

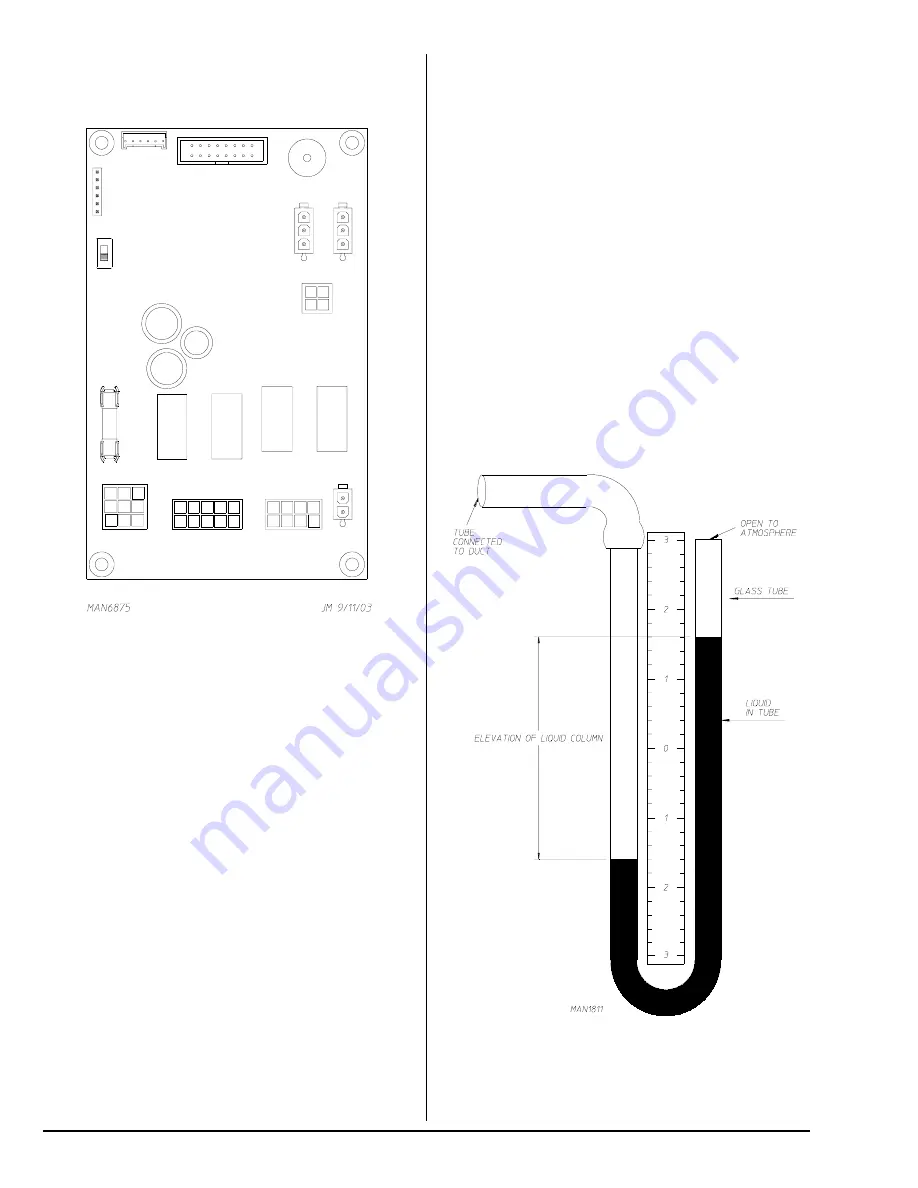

Static Pressure

The pressure of the air in sheet metal ducts is of great

importance for safe and efficient operation of the dryer. The

air pressures, as small as they are, have a large influence upon

the performance of the dryer. There are three (3) pressures

present within a duct. The velocity pressure, which is the

pressure due to the moving stream of air, the static pressure,

which is the outward push of the air against the walls of the

duct, and the total pressure, which is the sum of the static and

velocity pressures. Only the total and static pressures can be

measured. The velocity pressure is then calculated from the

difference between the two. The static pressure is the most

influential and determining factor in the design of a dryer duct

system. ADC recommends that the dryer exhaust duct static

pressure not exceed 0.3 in WC (0.74 mb).

Gages used to measure such small air pressures utilize the

elevation of a column of water. This form of gage is called a

manometer. One form of this gage is known as a U-tube and

is shown in

Illustration #1

. When one end of the tube is

connected to the duct, the static (outward) pressure within the

duct forces the water column to be depressed in one leg of the

U-tube and up in the other. The elevation of the water column

in

Illustration #1

is 3.2 inches (8 mb).

Illus. #1