Cleaning, maintenance and repair

150

KG / KX / KE BAH0063-6 04.16

12.3.2

Repositioning/replacing the gear wheels

on the WHG/KX / WHG/KG Special / Super (specialised workshop)

When the gearbox cover is opened, transmission fluid runs out.

To prevent contamination from escaping fluid,

raise the mounted implement using the tractor's three-point

hydraulics until the implement is inclined about 30° forwards

park the implement on solid ground and reduce the oil level by

draining off the transmission fluid.

Only reuse the collected transmission fluid if it has not been

contaminated by dirt particles.

DANGER

Secure the raised soil tillage implement which is attached to the

tractor against unintentional lowering by using suitable support

elements or a crane.

12.3.2.1 Repositioning/replacing the gear wheels on the WHG/KX

1. Couple the soil tillage implement to the

tractor.

2. Uncouple the seed drill.

3. Tilt the implement about 30° forwards using

the tractor's three-point hydraulic system.

4. Switch off the tractor PTO shaft, apply the

tractor parking brake, switch the tractor

engine off and remove the ignition key.

5. Secure the raised implement using suitable

support elements or a crane.

6. Open the gearbox cover.

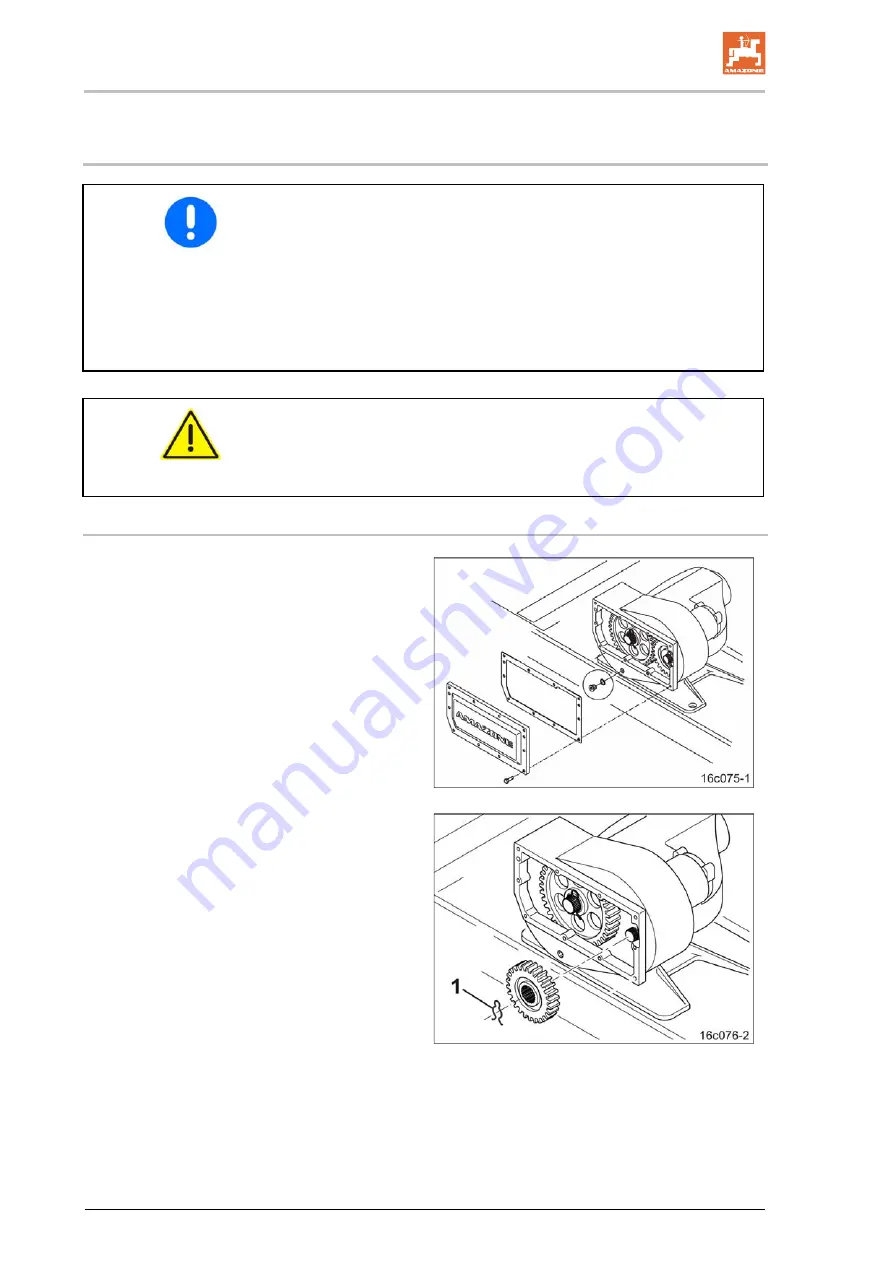

Fig. 157

7. Remove the retaining springs (Fig. 157/1).

8. Remove the gear wheels and, using the

speed table,

swap them around or

replace with a different set of gear

wheels.

9. Fit the retaining springs.

10. Close the gearbox cover and cover gasket.

11. Lower the implement.

12. Check the gearbox for leak points.

13. Check the oil level.

Fig. 158