23

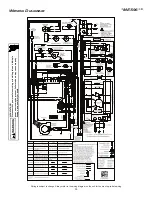

A semi-rigid connector to the gas piping can be used outside

the cabinet per local codes. From the elbow, the length of pipe

and the fittings required will vary by the side chosen, location

of union and cabinet width. The union may be placed inside

or outside of the cabinets.

Alternate

Gas Line

Location

Plug in

Alternate

Gas Line

Hole

* Ground

Joint

Pipe

Union

Gas Valve

*Ground

Joint

Pipe

Union

Manual Shut Off Valve

(upstream from

ground joint

pipe union)

Grommet

in Standard

Gas Line

Hole

Drip Leg

Burner

Manifold

* NOTE: Union may be inside furnace cabinet where allowed by local codes.

UPFLOW

Figure 29

Manual Shut Off Valve

(upstream from

ground joint pipe union)

Drip Leg

Plug in Alternate Gas Line Hole

Grommet in

Standard Gas Line Hole

Alternate

Union

Location

Burner

Drain Trap

Gas Valve

Plug in Main Gas Line Hole

Manifold

UPFLOW - HORIZONTAL LEFT

Figure 30

Gas Piping Checks

Before placing unit in operation, leak test the unit and gas con

-

nections.

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector, or other

approved testing methods.

NOTE:

Never exceed specified pressures for testing. Higher

pressure may damage the gas valve and cause subsequent

overfiring, resulting in heat exchanger failure.

Disconnect this unit and shutoff valve from the gas supply piping

system before pressure testing the supply piping system with

pressures in excess of ½

psig (3.48 kPa).

Isolate this unit from the gas supply piping system by closing

its external manual gas shutoff valve before pressure testing

supply piping system with test pressures equal to or less than

½

psig (3.48 kPA).

Circulating Air & Filters

Duct work - Air Flow

Duct systems and register sizes must be properly designed

for the CFM and external static pressure rat ing of the furnace.

Ductwork should be designed in accor dance with the rec

-

ommended methods of “Air Conditioning Contractors of

America” Manual D.

Install the duct system in accordance with Standards of the

National Board of Fire Underwriters for the Installation of Air

Conditioning, Warm Air Heating and Ventilating Systems.

Pamphlets No. 90A and 90B.

.

Figure 31

A closed return duct system must be used, with the return duct

connected to the furnace.

NOTE:

Ductwork must never be

attached to the back of the furnace.

For upflow installations

requiring 1800 CFM or more, use either two side returns or

bottom return or a combination of side/bottom. Flexible joints

may be used for supply and return con nections to reduce

noise transmission. To prevent the blower from inter fering

with combustion air or draft when a central return is used, a

connecting duct must be installed between the unit and the

utility room wall. Never use a room, closet, or alcove as a

return air chamber.

Checking Duct Static

E

DGES

OF

SHEET

METAL

HOLES

MAY

BE

SHARP

. U

SE

GLOVES

AS

A

PRECAUTION

WHEN

REMOVING

SHEET

METAL

FROM

RETURN

AIR

OPENINGS

.

WARNING

Refer to your furnace rating plate for the maximum ESP

(external duct static) rating.