21

To ensure proper unit grounding, the ground wire should run

from the furnace ground screw located inside the furnace junc

-

tion box all the way back to the electrical panel.

NOTE:

Do not

use gas piping as an electrical ground. To confirm proper

unit grounding, turn off the electrical power and perform the

following check.

1. Measure resistance between the neutral (white)

connection and any unpainted surface.

2. Resistance should measure 10 ohms or less.

This furnace is equipped with a blower door interlock switch

which interrupts unit voltage when the blower door is opened

for servicing. Do not defeat this switch.

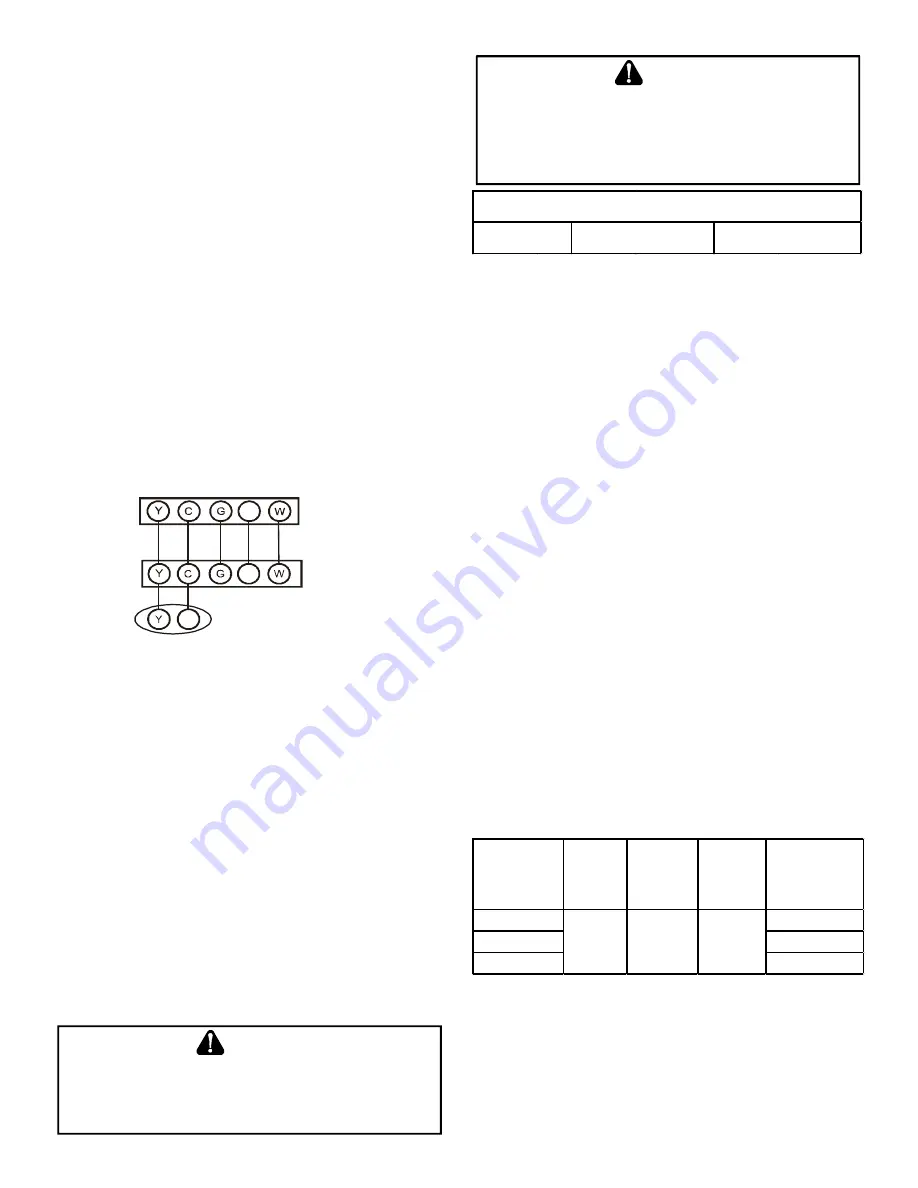

24 Volt Thermostat Wiring

Low voltage connections can be made through either the right or

left side panel. Thermostat wiring entrance holes are located in

the blower compartment. The following figure shows connections

for a “heat/cool system”.

This furnace is equipped with a 40 VA transformer to facilitate

use with most cooling equipment. Consult the wiring diagram,

located on the blower compartment door, for further details of

115 Volt and 24 Volt wiring.

R

C

Furnace Integrated

Control Module

Remote Condensing Unit

(Single-Stage Cooling)

R

Room

Thermostat

Figure 28

Single-Stage Heating Thermostat Application

A single-stage thermostat with only one heating stage is

needed to control this furnace.

Fossil Fuel Applications

This furnace can be used in conjunction with a heat pump in a

fossil fuel application. A fossil fuel application refers to a combined

gas furnace and heat pump installation which uses an outdoor

temperature sensor to determine the most cost efficient means

of heating (heat pump or gas furnace).

Strictly follow the wiring guidelines in the fossil fuel kit installation

instructions. All furnace connections must be made to the furnace

integrated control module and the “FURNACE” terminal strip on

the fossil fuel control board.

Gas Supply and Piping

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

GAS

MANIFOLD

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

. O

NLY

MINOR

ADJUSTMENTS

SHOULD

BE

MADE

BY

ADJUSTING

THE

GAS

VALVE

PRESSURE

REGULATOR

.

CAUTION

WARNING

P

OSSIBLE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

MAY

OCCUR

IF

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

. T

HE

APPROPRIATE

KITS

MUST

BE

APPLIED

TO

ENSURE

SAFE

AND

PROPER

FURNACE

OPERATION

. A

LL

CONVERSIONS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER

OR

SERVICE

AGENCY

.

Natural Gas

Minimum: 4.5" W.C. Maximum: 10.0" W.C.

INLET GAS SUPPLY PRESSURE

TABLE 4

The furnace rating plate includes the approved furnace gas input

rating and gas types. The furnace must be equipped to operate

on the type of gas applied. This includes any conversion kits

required for alternate fuels and/or high altitude.

Inlet gas supply pressures must be maintained within the ranges

specified in table 4. The supply pressure must be constant

and available with all other household gas fired appliances

operating. The minimum gas supply pressure must be main

-

tained to prevent unreliable ignition. The maximum must not

be exceeded to prevent unit overfiring.

High Altitude Derate

GMES96-U furnaces do not use ID plugs, thus do not require

any ID plug changes.

The furnace, as shipped, requires no change to run between

0-4500 feet. At all altitudes the air temperature rise must be

within the range listed on the the Specification Sheet ap

-

plicable to your model for the fuel used. Manifold pressure

adjustments and combustion analysis are required for all

installations above 4500 ft. Refer to “Gas Supply Pressure

Measurement” section for instruction on how to properly

measure and adjust manifold “outlet” pressure. The furnace

should operate for a minimum of 15 minutes before taking a

combustion sample. Combustion samples should be taken

from beyond the furnace exhaust and must be within provided

CO2% range. See table 5 for recommended manifold pres

-

sure adjustments and proper CO2% range. Gas heating val

-

ues can vary; further pressure adjustment may be necessary

to ensure furnace operates within acceptable CO2 range.

MODEL

Manifold

Presure

at 5000ft

Manifold

Pressure

at 7500ft

C02%

Natural

Gas

Max Allowable

Venting (3 in

only)

*MES960403BU

100ft

*MES960603BU

100ft

*MES960805CU

80ft

2.5" w.c. 2.4" w.c.

6.5 - 8.5

TABLE 5

Gas Valve

This unit is equipped with a 24 volt gas valve controlled during

furnace operation by the integrated control module. Taps for

measuring the gas supply pressure and manifold pressure are

provided on the valve.

The gas valve has a manual ON/OFF control located on the valve