(Refer to Monitoring Temperature Values).

A skilled and experienced technician must examine the heating

and air outlet system before the machine is put in operation again.

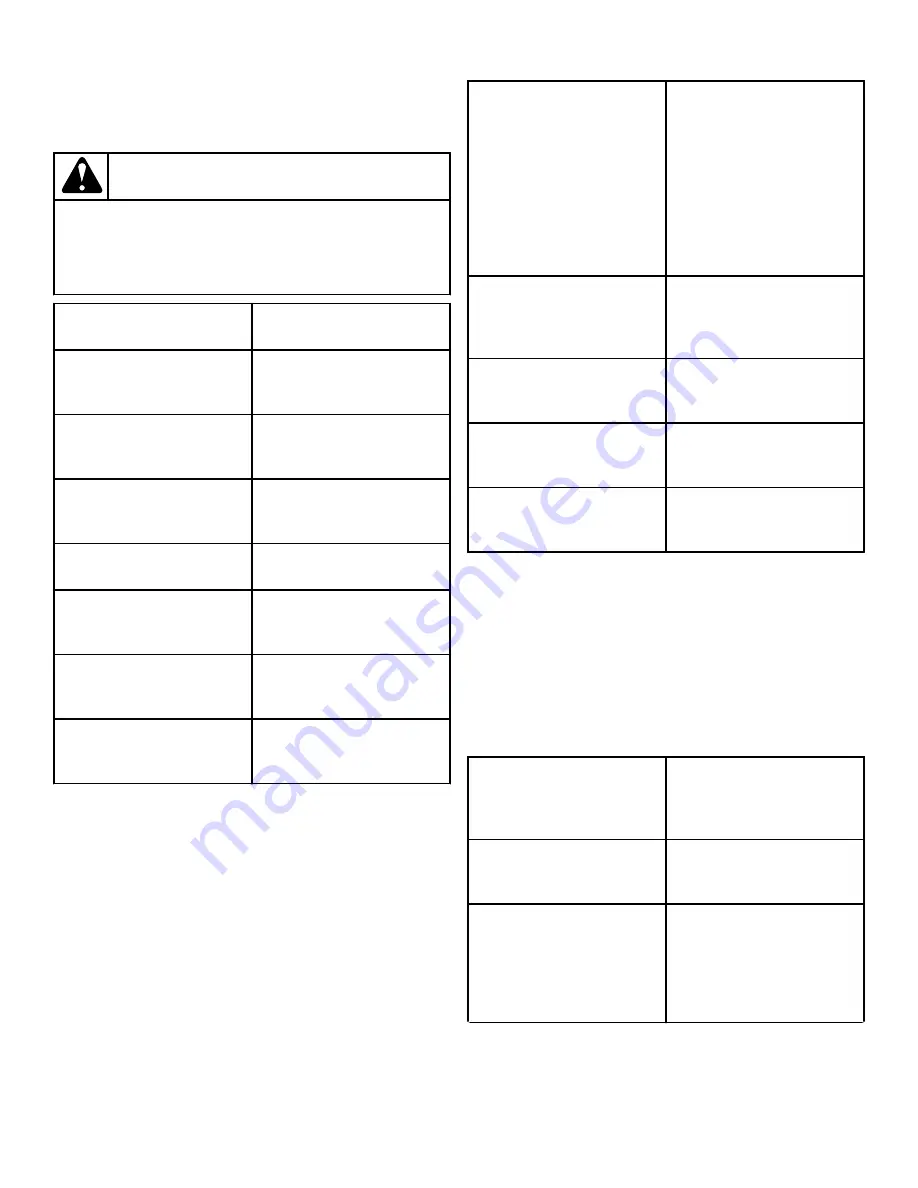

WARNING

IF FAILURE 37 OCCURS WE CAN EXPECT THERE IS

RISK OF BURN AND NECESSARY ACTIONS MUST

BE TAKEN TO REDUCE TEMPERATURE.

C143

1. Check the air outlet system. If the airflow is not sufficient,

adjust the air outlet system.

2. Check the temperature sen-

sor.

If the temperature sensor is not

measuring correctly, replace

the temperature sensor.

3. Check the heating system.

If the heating system is bro-

ken, repair or replace the heat-

ing system.

4. Check the heating contactor

(valve).

If the heating contactor (valve)

is not functional, repair or re-

place the component.

5. Check the wiring.

If the wiring is damaged, re-

pair the wiring.

6. Check the Safety Thermo-

stats ST1 & ST2.

The Safety Thermostats should

go open before failure 37 is

generated.

7. Check the output relay that

controls the heating system.

If the output relay is not func-

tional, replace the control

board.

8. Check the input Signal by

monitoring the state at the

Service menu.

If the input is not functional,

replace the control board.

Failure 39: Error Fan

Machine With Heat Pump (HP)

Error 39 is displayed as soon as an electronic protection of the

fan motor is activated.

A qualified technician must examine the water heating system

and air exhaust system before the machine is put in operation

again.

DIAGNOSE:

1. Check if the contact of the

electronic protection of the

fan motor is connected when

the fan is operating (CMF –

On).

NOTE: If supply voltage

is not fed into the fan,

the protection contact is

in the open state.

If the contact is disconnected,

the fan motor is overheated

or the fan is damaged: wait

until the fan cools down - ap-

prox. 15 minutes. In case the

fault is a temperature prob-

lem and the fan is not dam-

aged, the error will not reac-

tivate when the machine is

restarted.

2. Check if the airflow is ob-

structed. Also check if the ro-

tation of the drum and fan are

obstructed/limited.

Check if the lint filter is clog-

ged, if so, clean it. Check the

heat exchangers, if clogged

with dust, clean them.

3. In case the electronic pro-

tection of the motor does not

connect within 15 minutes.

It is likely the fan is damaged,

replace the fan.

4. Check if the power supply

and control circuits of the fan

are interrupted.

If the circuits are interrupted,

repair them.

5. Check the input signal based

on the state as indicated in the

Service menu.

If the input is not functional,

replace the programmer board.

Failure 40: Phase Error

Machine With Heat Pump (HP)

Error 40 may occur when the sequence of phases is incorrectly

connected in the power supply system.

If error 40 occurs during the operation, it is either due to a failure

of one phase of the power supply system or due to a significant

difference of voltage in the individual phases.

DIAGNOSE:

1. The fault occurred after the

machine was installed.

Change the sequence of phases

respective to the power supply

system on the machine supply

cable.

2. The fault occurred during

machine operation.

Check if unwanted failures in

the machine power supply sys-

tem occurred.

3. The fault occurred during

machine operation - check (ac-

cording to the wiring diagram)

if interruptions in the power

supply circuits of the individu-

al machine circuits occurred.

Check the state of the pilot re-

lay which monitors the phases.

If the wiring is not continuous,

repair the wiring.

Table continues...

Troubleshooting

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

51

Part No. D1621ENR3

Summary of Contents for SGHP190E

Page 2: ......