20

801805

Section 3 Troubleshooting (Dryer)

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15. TIMER DOES NOT ADVANCE IN AUTOMATIC CYCLE

POSSIBLE CAUSE

TO CORRECT

Inoperative cycling thermostat.

• Test thermostat and replace if inoperative.

Inoperative resistor (Electric Models).

• Test resistor and replace if inoperative.

Heater assembly does not heat or burner does not

ignite.

• Refer to Paragraph 4.

Heater assembly or burner cycles off prematurely.

• Refer to Paragraph 8.

Improper or inadequate exhaust system.

• Refer to INSTALLATION INSTRUCTIONS (supplied

with dryer) for exhaust requirements.

Drying large load.

• Timer will not advance until the load is almost dry.

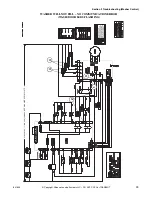

Broken, loose or incorrect wiring.

• Refer to wiring diagram.

Timer motor is inoperative.

• Select a drying cycle and activate start switch.

• Rotate timer knob until signal sounds.

• Release timer knob.

• Signal should stop within ten minutes. If not, replace

timer.

Inoperative seals (air leaks).

• Check and replace any inoperative seals in the following

areas:

1. Seal between loading door and front panel.

2. Seal between front panel and front bulkhead.

3. Seal between blower cover and air duct.

4. Seal between cylinder and front or rear bulkhead.

5. Gap between air duct and filter mounting.