Rockwell Automation Publication 1756-UM540E-EN-P - December 2017

175

Troubleshoot Your Module

Chapter 9

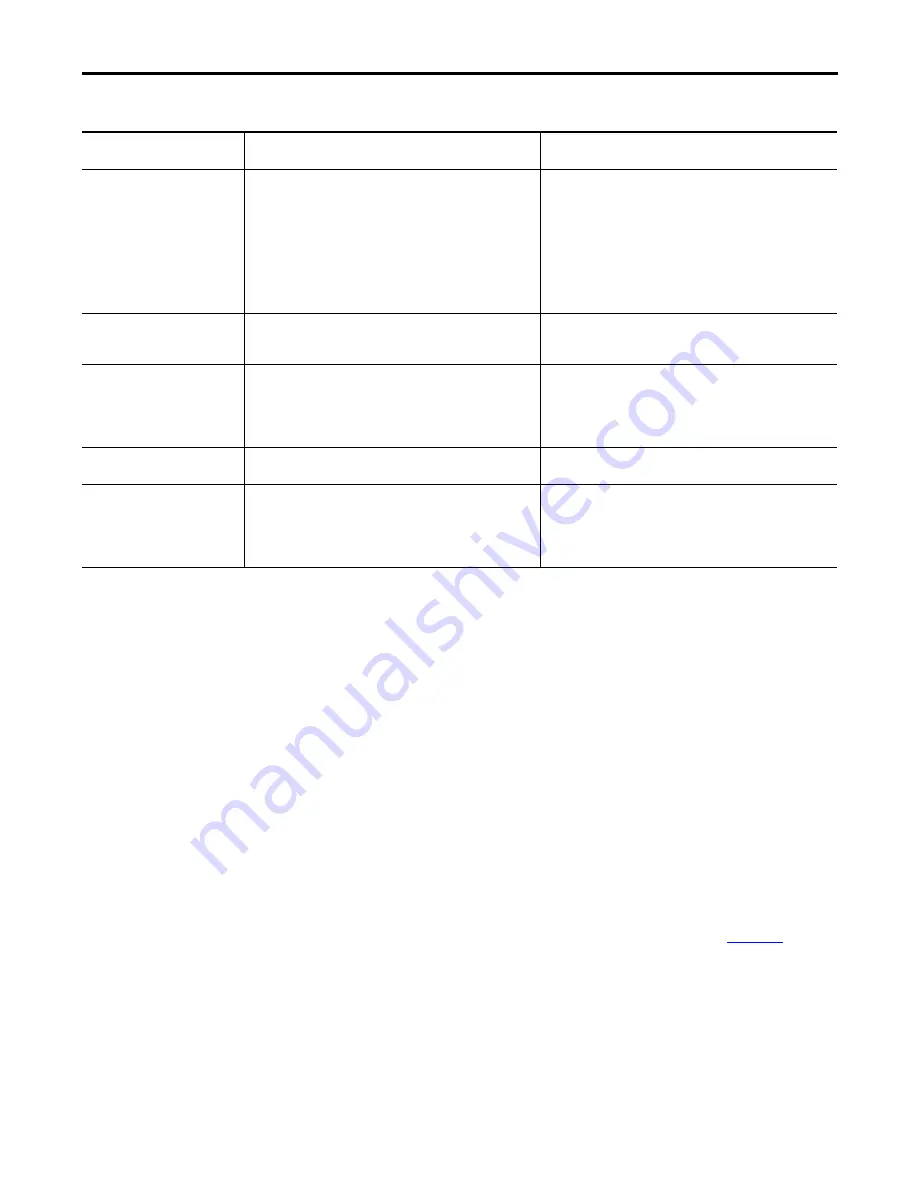

1756-IF8I Module - Incorrect Input Voltage/Current Readings

To determine the cause of the incorrect reading, first determine the nature of the

incorrect reading. For example, the module can perform as follows:

•

The module always reads maximum.

•

The module always reads minimum/zero/negative.

•

The module reads voltage/current erratically (data jumping around).

•

The module reads with an offset over the entire range.

First, complete the following tasks.

1.

Check the status indicators to verify that the module is powered and

communicating.

Red or flashing green status indicators indicate a problem. For more

information on the 1756-IF8I module status indicators,

2.

Make sure that wiring is intact and correct, and that the current or voltage

input is wired to the corresponding terminals and with proper polarity.

Incorrect reading soon after module

installation

One of the following:

•

Incorrect readings at initial module installation and configuration

are often the result of installation and configuration errors.

•

Incorrect readings at installation of an existing, previously-

working module are more likely the result of a hardware failure.

One of the following:

•

If error is occurring on a new module installation and

configuration, make sure that those tasks were completed

corrected and correct any errors you find.

•

If the error is occurring on an existing, previously-working

module, diagnose the hardware failure and correct it. If more than

one channel is experiencing the incorrect readings in this case,

disconnect all thermocouples except one. This can help determine

if it is external hardware or the module itself is the cause

Grounded RTD

Due to the module's excitation current traveling on an RTD lead that

is grounded there can be errant ground paths which would cause

inaccuracies to the RTD measurements.

Eliminate the ground or use a signal conditioner/isolator.

Lead Compensation

An RTD sensor requires at least three leads to compensate for lead

resistance error, caused by resistance mismatch. The amount of error

eliminated depends upon the difference between the resistance

values of the lead wires. The closer the resistance values are to each

other, the greater the amount of error that is eliminated

To verify that the lead resistance values match as closely as possible:

•

use heavy gauge wire (16–18 gauge)

•

keep lead distances less than 1000 feet

•

use quality cable that has a small tolerance impedance rating.

Sensor Offset

The software configured Sensor Offset value is summed with the

input data value.

Verify that the Sensor Offset feature is desired.

Programming and Configuration

One of the following:

•

Input value read from correct data tag.

•

Channel configured for correct range.

•

Signal and Engineering units are set correctly and equal.

If the incorrect input data value is in a secondary location, for

example, an HMI device, verify the base tag value in the controller.

Correct module configuration as needed.

Table 25 - Troubleshoot Incorrect RTD Readings (continued)

Possible Cause of Incorrect

Reading

Description

Recommended Action