6-39

ASDI Operations and Maintenance – TX Models – P/N: 52368

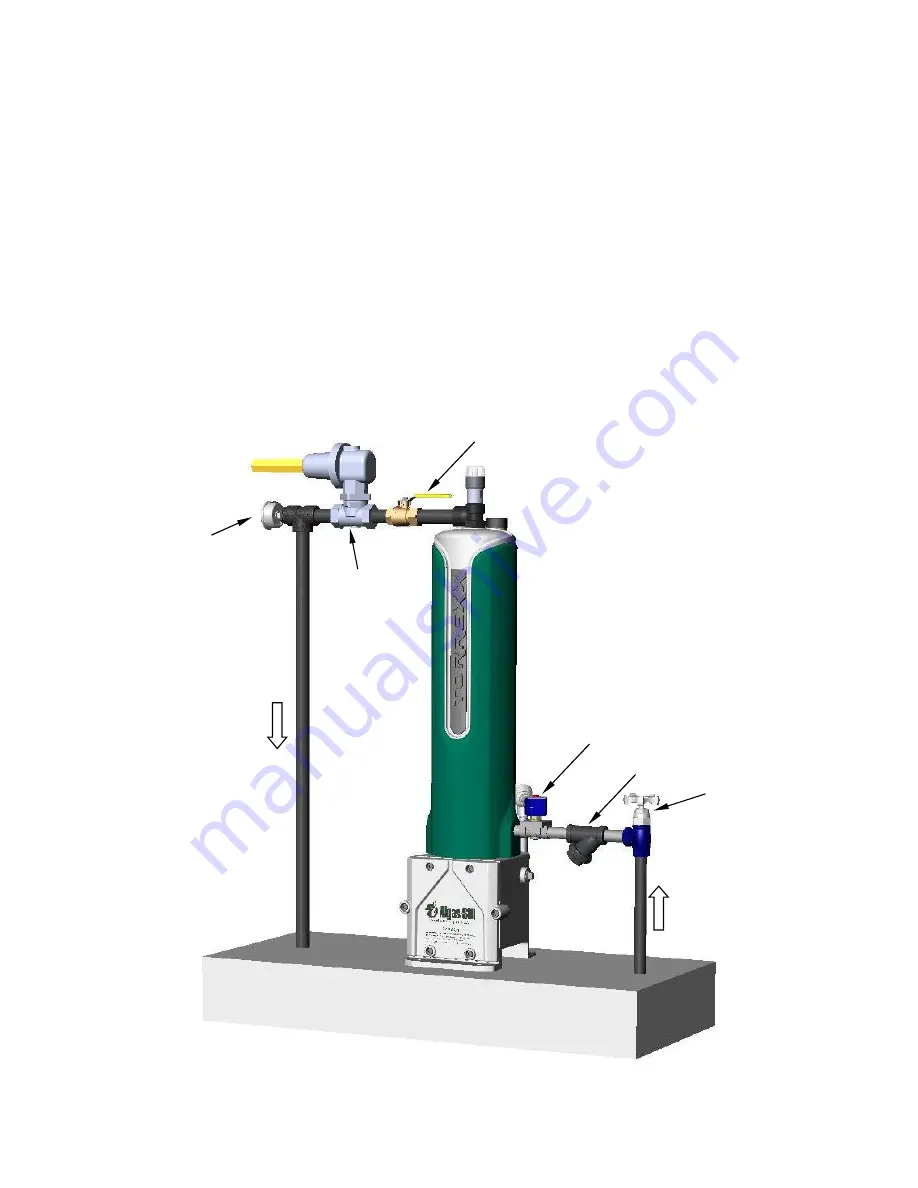

Solenoid

Valve

Leak

Test

1) Shut off the outlet isolation valve. The inlet isolation valve should be

open. Start the vaporizer and allow it to heat up until the heaters shut off.

This allows any accumulated liquid in the vaporizer to be forced back

toward the supply tank.

2) Disconnect the vaporizer by shutting off the power at the disconnect.

Shut off the inlet isolation valve. Cautiously bleed off any LPG pressure

in the vaporizer and outlet supply piping. When the pressure reaches no

pressure in the vaporizer, remove and then reinstall pressure gauge and

verify 0 pressure.

3) Turn on the inlet isolation valve. The solenoid valve is closed and you

should not have any pressure build up in the vaporizer. If pressure

increases, the solenoid valve is leaking and needs to be repaired or

replaced.

Figure 15 – Solenoid Valve Leak Test Components

VAPOR DISCHARGE OUTLET

ISOLATION VALVE

SOLENOID VALVE

STRAINER

LIQUID INLET

ISOLATION VALVE

LIQUID IN

VAPOR OUT

FIRST STAGE

REGULATOR

VAPOR

PRESSURE

GAUGE

Summary of Contents for TORREXX TX100

Page 8: ......

Page 56: ...APPENDIX A TECHNICAL INFORMATION ...

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 83: ...ASCO Valve used by Algas SDI ...

Page 86: ...ASCO Valve used by Algas SDI ...

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......