2600 series Hydraulic Tooling

(HK914)

Alcoa Fastening Systems

5

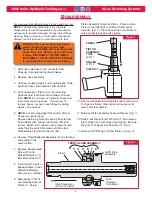

Piston

Trigger

Switch

Depressed

Hydraulic

Hoses

RETURN

side

PULL

side

Pressurized

Hydraulic Fluid

Return

Hydraulic Fluid

Piston Travel

Trigger

witch

Depressed

H d

li

Dump

Valve

H

Du

Va

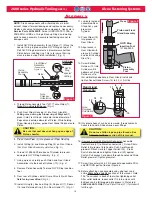

Piston

Trigger

Switch

Released

Hydraulic

Hoses

RETURN

side

PULL

side

Piston Travel

Trigger

witch

Released

H d

li

Dump

Valve

Pressurized

Hydraulic Fluid

Return

Hydraulic Fluid

Pull Pressure

(Pull Cycle)

When the Trigger Switch is depressed,

pressurized hydraulic fluid moves

through the PULL hose to the front side

of the Piston. The piston and nose

assembly collet move rearward, installing

the fastener. When the Piston reaches

the end of the PULL stroke, it uncovers

flats on the back of the Dump Valve.

These flats are designed to provide a

passage for hydraulic fluid from the PULL

side to the RETURN side of the Piston,

unloading or “dumping” the pressurized

fluid back to the Powerig tank.

Return Pressure

(Return Cycle)

When the trigger is released,

pressurized hydraulic fluid is directed to

the rear side of the Piston, causing the

Piston and collet to move forward,

allowing fluid on the PULL side to flow

back through the PULL side hose to the

Powerig tank, and pushing the nose

assembly and tool off of the swaged

(installed) fastener. When the Piston

reaches the end of the RETURN

stroke, pressure is built up, causing the

Powerig to shut off, completing the

cycle.

P

P

RINCIPLE

RINCIPLE

OF

OF

O

O

PERATION

PERATION