2600 series Hydraulic Tooling

(HK914)

Alcoa Fastening Systems

14

Always check the simplest possible cause of a

malfunction first (example: a loose or disconnected

trigger line). Then proceed logically and eliminate

each possible cause until the defect is found.

Where possible, substitute known good parts for

suspected defective parts. Use the following steps

as an aid in troubleshooting.

1.

Tool fails to operate when trigger is pressed.

a. Inoperative POWERIG® Hydraulic Unit. See

applicable instruction manual.

b. Loose electrical connections.

c. Damaged trigger assembly.

d. Loose or faulty hose coupling.

2.

Tool operates in reverse.

a. Reversed hose connections between hydraulic

unit and tool.

3.

Tool leaks hydraulic fluid.

a. Defective tool O-rings or loose connections at

tool.

4.

Hydraulic couplers leak fluid.

a. Damaged or worn O-rings in Coupler Body

Coupler

5.

Hydraulic fluid overheats.

a. Unit not operating properly. See units manual.

b. Unit running in reverse (918; 918-5 only). See

unit’s manual.

6.

Tool operates erratically and fails to install

fastener properly.

a. Low or erratic hydraulic pressure. Air in

system.

b. Damaged or worn Piston O-ring in tool.

c. Excessive wear on sliding surfaces of tool

parts.

7.

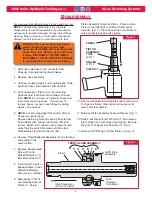

Pull grooves on fastener pintail stripped during

PULL stroke.

a. Operator not sliding anvil completely onto

fastener pintail.

b. Incorrect fastener grip.

c. Worn or damaged jaw segments.

d. Metal particles in jaw grooves.

e. Excessive sheet gap.

8.

Collar of fastener not completely swaged.

a. Improper tool operation. See No. 6.

b. Scored anvil.

9.

Tool "hangs up" on swaged collar of fastener.

a. Improper tool operation. See No. 6.

b. RETURN pressure too low.

c. Not enough collar lubricant.

d. Nose assembly not installed correctly.

10.

Pintail of fastener fails to break.

a. Improper tool operation - - see No. 6.

b. Pull grooves on fastener stripped - - see No. 7.

c. PULL pressure too low.

11.

Nose will not release broken pintail.

a. Nose assembly not installed correctly.

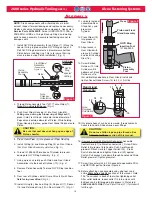

Service Kit:

All Models

- 2600KIT

Assembly Tool Kit:

Assembly Tool Kit: All Models

- 123110

Includes: (Figs. 3 & 6))

Spacer

- 123112

Piston Assembly Tool

- 123111

GLYD Ring Insertion Tool

- 121694-2600

T

T

ROUBLESHOOTING

ROUBLESHOOTING

K

K

ITS

ITS

& A

& A

CCESSORIES

CCESSORIES