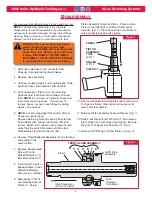

POWER SOURCE CONNECTIONS

Coat hose fitting threads with a non-hardening

Teflon

TM

thread compound such as Slic-tite.

TM

1. Use Huck POWERIG

®

Hydraulic Unit, or

equivalent, that has been prepared for operation

per applicable instruction manual. Check both

PULL and RETURN pressures, and if required,

adjust to pressures given in

S

S

PECIFICATIONS

PECIFICATIONS

.

2. First, turn hydraulic unit to OFF, and then,

disconnect power supply from unit. Connect

tool's hoses to Powerig unit.

3. Connect tool's control switch electrical cord to

hydraulic unit.

4. Connect hydraulic unit to power supply. Turn

unit to ON. Hold tool trigger depressed for 30

seconds; depress trigger a few times to cycle

tool and to circulate hydraulic fluid. Observe

action of tool and check for leaks. Turn unit to

OFF.

5. Select nose assembly for fastener to be

installed. Disconnect tool's control switch

electrical cord from hydraulic unit; disconnect

unit from power supply. Attach nose assembly

to tool.

6. Reconnect hydraulic unit to power supply.

Reconnect tool's switch control cord to unit.

Check operation of nose assembly; install

fasteners in test plate of correct thickness with

proper size holes. Inspect installed fasteners. If

fasteners do not pass inspection, see

T

ROUBLESHOOTING

to locate and correct tool

malfunction.

WARNING: Be sure to connect Tool’s

hydraulic hoses to POWERIG Hydraulic

Unit before connecting Tool’s switch

control cord to unit. If not connected in

this orderand disconnected in the

reverse order, severe personal Injury

may occur.

2600 series Hydraulic Tooling

(HK914)

Alcoa Fastening Systems

7

P

P

REPARATION

REPARATION

FOR

FOR

U

U

SE

SE

WARNING: Correct PULL and

RETURN pressures are required for

operator’s safety and for Installation

TooI’s function. Pressure Gauge T-

124883CE is available for checking

pressures. See Tool S

PECIFICATIONS

and Gauge Instruction Manual.

Failure to verify pressures may result

in severe personal injury.

WARNINGS:

Read full manual before using tool.

A half-hour training session with qualified

personnel is recommended before using

Huck equipment.

When operating Huck installation equipment,

always wear approved eye and ear protection.

Be sure there is adequate clearance for the

operator’s hands before proceeding.

*

Slic-Tite is a registered trademark of LA-CO Industries, Inc.

*

TEFLON is a registered trademark of DuPont Corp.

*

LUBRIPLATE is a registered trademark of LUBRIPLATE Lubricants Co.

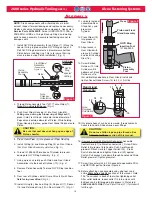

GOOD SERVICE PRACTICES

Sealants, Lubricants, Hydraulic Fluid &

Service Kits

•

Rub Slic-Tite TEFLON thread compound, or

equivalent, on pipe threads to prevent leaks

and for ease of assembly.

•

Smear LUBRIPLATE

®

*

No. 130-AA, or

equivalent, on O-rings and mating surfaces to

prevent damaging O-rings on rough or sharp

surfaces. Also, increases ease of assembly.

(LUBRIPLATE in a tube, 502723).

CAUTION: Do not let disconnected hoses and

couplers contact a dirty floor. Keep harmful

material out of hydraulic fluid. Dirt in

hydraulic fluid causes valve failure In Tool

and In POWERIG Hydraulic Unit.

CAUTION: Do not use TEFLON

®

* tape on pipe

threads. Pipe threads may cause tape to shred

resulting in tool malfunction. (Slic-Tite is

available in stick form as Huck P/N 503237.)

Huck recommends that only Huck Powerig

Hydraulic Units be used as a power source

for Huck installation equipment. Hydraulic

power units that deliver high pressure for

both PULL and RETURN, AND ARE NOT

EQUIPPED WITH RELIEF VALVES ARE

SPECIFICALLY NOT RECOMMENDED AND

MAY BE DANGEROUS.