AL-MEISTER ALM3222 Instruction Manual <Rev.2>

Page

28

of

52

5. AUTOMATIC OPERATION (cont’d)

5-2. SETTINGS

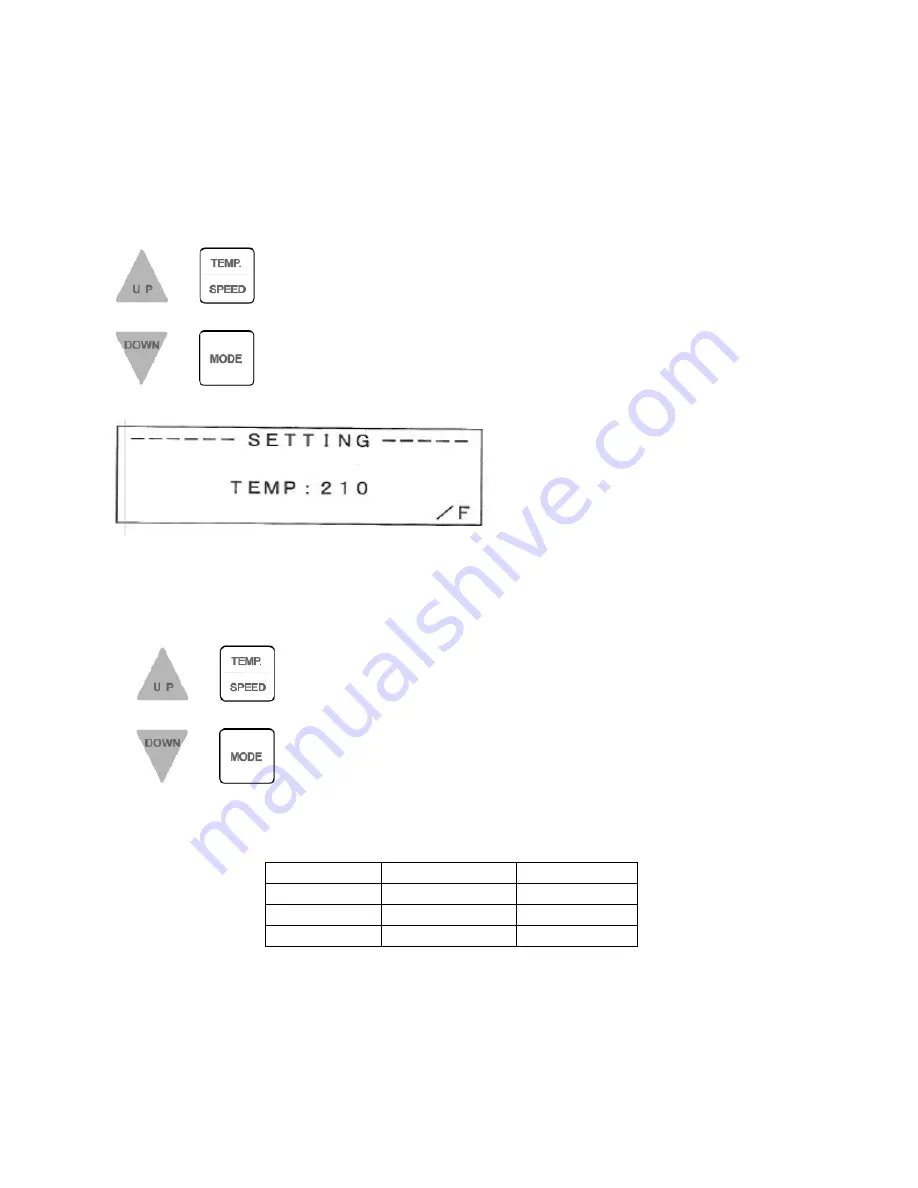

5-2-1. SET TEMPERATURE

Press TEMP./SPEED button once.

* The default is set at 210F. This is the

power on default and may not be hot

enough for some paper stocks.

Press UP or DOWN button to set temperature. Temperature can be set between 170F and 270F in 10F

increments. The temperature display blinks.

Press TEMP./SPEED button to confirm the temperature.

This table shows an example of temperature settings for different film and paper thicknesses. It also

pays to experiment with different temperatures and speeds to achieve quality laminations.

Film thickness Copying paper

Thicker paper

1.5mil

210F - 40"/min

220F - 40" /min

3mil – 4mil

220F - 40" /min

230F - 40" /min

5mil

230F - 40"/min

240F - 40" /min