04 * GB_neu.qxp 08.06.2005 9:39 Uhr Seite 2

7

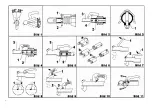

fitting bolt (Fig 2 / Item1). Leave bolts for centring the

shock absorber in the draw bar tube.

Push the ball type coupling and if necessary the

spacer hoop (Fig 5 /Item 4) on the draw bar, so that

the fastening drill holes match. Position distance

bush.

Punch the hexagonal screw M12 x75/80 (Fig 2/Item

2) using the fitting bolt. (Shock absorber is threaded

on).

Insert the second hexagonal screw M12 x75/80 (Fig

2/Item 4).

ATTENTION:

To ensure that the shock absorber is

threaded on, push the draw bar in and out.

If resistance can be felt, the shock absorber is hung

in position.

Screw self-locking hexagonal nuts (use new nuts

supplied) on the screws and tighten using tightening

moment (see table).

Note:

Where there is a cross union a profile disk (Fig

3 / Item1) must be included with the vertical screw.

ATTENTION:

Self-locking nuts may only be used

once.

Shock absorber NOT hung on the fixing bolt.

Slacken and remove self-locking nuts for the

hexagonal bolts. Pull hexagonal bolts out; lift off old

ball type coupling. Push ball type coupling onto the

drawbar so that the fastening drill holes match with

one another. Put distance bush in place (Fig 5).

Insert hexagonal bolts M12x75/80 (Fig 4/Item 1 and

2) and thread distance bush on with them.

Screw self-locking hexagonal nuts on the screws and

tighten using tightening moment (see table).

ATTENTION:

Where there is a cross union a profile

disk (Fig 3 / Item1) must be included with the vertical

screw.

ATTENTION:

Self-locking nuts may only be used once.

TIGHTENING MOMENT:

* Screw quality 8.8 ** AE = overrun device

Operation

for model AK 160/ AK 300/ AK 350:

Swivel range:

Keep swivel range of vertical

±

25

°

(Fig. 1).

Keep swivel range of horizontal

±

20

°

(Fig. 1).

ATTENTION:

If this is exceeded the components will

be overloaded. Function is no longer ensured!

Coupling in place:

Open the ball-type coupling drawbar = to do this, pull

the coupling handle upward in the direction of the

arrow (Fig 7/Item.1). The coupling mechanism has

an “open position”, i.e. as long as the coupling is not

placed on the ball, the coupling handle remains open.

Place the opened ball type coupling drawbar on the

trailer ball of the towing vehicle.

The tongue load causes the ball type coupling

drawbar to lock into place into the starting position

with an audible sound automatically.

For safety reasons also push the handle down

manually (Fig 7 / Item 1).

It is locked and secured automatically.

The trailer ball is coupled correctly when the trailer

device pushes out the green cylinder of the locking

display and the green cylinder becomes visible (Fig 7

/ Item 2).

The coupling mechanism is locked correctly when the

coupling handle can no longer be pushed down by

hand.

ATTENTION: If the ball type coupling drawbar is no

longer coupled to the trailer ball, the trailer can

detach itself from the towing vehicle.

Uncoupling:

Open the coupling handle and lift the ball type

coupling drawbar up on the trailer coupling on the

towing vehicle.

Lifting up and off where there are larger tongue loads

can be made easier by using a jockey wheel.

Wear display:

A wear display on the coupling handle (Fig, 8) shows

if the wear limit of the trailer ball of the towing

vehicle, or the trailer coupling has been reached or

not.

To do this couple the ball type coupling drawbar to

the towing vehicle and drive approx. 500 m with the

car & trailer. The driving movement will give the

coupling mechanism maximum reset. Finally check

the wear as follows.

If the green display is visible on the coupling handle

when coupled (see Fig 8 / Item 2) the ball type

coupling drawbar in its new state or the wear in the

trailer ball is within the permitted boundary/ies.

If the green display on the coupling handle is

completely covered when coupled and only the red

display is visible (Fig 8/Item 1) then the causes are as

follows as a rule:

• Trailer ball in the bottom most wear boundary Ø 49

or less - ball type coupling drawbar without wear.

• Ball type coupling drawbar and trailer ball show

wear.

Overrun device model**

Tightening moment*

AL-KO 60S/2

60 Nm

AL-KO 90S/3

70 Nm

all other overrun devices

86 Nm

AL-KO 2,8VB/1

210 Nm

Summary of Contents for 605 363

Page 1: ...605 363 Zugkugelkupplung DK RUS I H SLO F LT N LV S CZ D NL EST SK GB FIN P E PL GR f...

Page 3: ...1...

Page 45: ...2 4 43...

Page 49: ...2 4 47...

Page 53: ...2 4 1 51...

Page 57: ...8 1 55 2 4...

Page 61: ...2 4 59...

Page 63: ...50 30 RUS_neu qxp 08 06 2005 11 21 Uhr Seite 4 61...

Page 65: ...2 4 63...

Page 69: ...2 4 67 67...

Page 73: ...2 4 71...

Page 77: ...2 a 4 75...

Page 81: ...2 4 79...

Page 85: ...2 4 83...

Page 87: ...AL KO AL KO 371 912 ETI 50mm GR_neu qxp 08 06 2005 11 31 Uhr Seite 5 85...