31

■

SUPPLEMENT ON DRAIN PIPING

1. Drain hose installation

* After checking the drainage, wrap the supplied packing and drain pipe insulator around the pipe.

NOTE

There is possibility to cause water leakage unless the above steps are carried out.

2. Checkpoint after installation

After installation of indoor and outdoor units, panels and electrical wiring, check the following items.

Checkpoint Symptom

Check

Remark

1 Are indoor and outdoor units correctly installed?

Fall, vibration, noise

2 Is gas leakage tested?

No cooling, no heating

3

Is insulation completed?

(Refrigerant piping and drain piping)

water leakage

4 Is drain water running smoothly?

water leakage

5 Does the power voltage meet the nameplate?

Inoperative, burnout

6 Is there miswiring or incorrect connection?

Inoperative, burnout

7 Is the ground construction completed?

Ground leakage

8

Is the wire gauge followed by the recommended

specifications?

Inoperative, burnout

9

Are the air intake and air outlet of the indoor and

outdoor units sealed by any obstacles?

No cooling, no heating

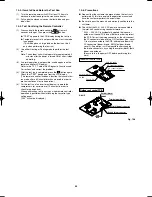

Drain port

Indoor unit

Indoor unit

Drain port may possibly be damaged

if polyvinyle chloride adhesive is used.

*

Apply approx. 2g of the adhesive on both sides of the

supplied drain hose with a joint socket and hard PVC pipe.

Wipe off the protrusion-adhesive with a soft cloth.

*

However, do not use the hard

PVC pipe joint allowable more

than 55mm insertion.

*

Do not use adhesive here.

20mm or more

5mm

57mm

Align the hose band with end of the hose and

tighten so that it does not contact the bead.

(Torque 2.5 - 3.4N.m)

Adhere with polyvinyle chloride adhesive.

Hose band

Bead

Bead

Packing (supplied)

Drain insulator (supplied)

Note:

Be sure to tightly insert the hard

PVC pipe joint (including elbow)

minimum 20mm or more.

Soft polyvinyle chloride socket

Drain hose

Hard PVC socket (VP25)

Hard PVC pipe

(VP25 field supplied)

(supplied)

(Drainage check section

on drain port, transparent,

ABS resin)

(supplied)

Drain port

Indoor unit

Indoor unit

Drain port may possibly be damaged

if polyvinyle chloride adhesive is used.

*

Apply approx. 2g of the adhesive on both sides of the

supplied drain hose with a joint socket and hard PVC pipe.

Wipe off the protrusion-adhesive with a soft cloth.

*

However, do not use the hard

PVC pipe joint allowable more

than 55mm insertion.

*

Do not use adhesive here.

20mm or more

5mm

57mm

Align the hose band with end of the hose and

tighten so that it does not contact the bead.

(Torque 2.5 - 3.4N.m)

Adhere with polyvinyle chloride adhesive.

Hose band

Bead

Bead

Packing (supplied)

Drain insulator (supplied)

Note:

Be sure to tightly insert the hard

PVC pipe joint (including elbow)

minimum 20mm or more.

Soft polyvinyle chloride socket

Drain hose

Hard PVC socket (VP25)

Hard PVC pipe

(VP25 field supplied)

(supplied)

(Drainage check section

on drain port, transparent,

ABS resin)

(supplied)

Airwell̲PAC-i̲eng.indb 31

Airwell̲PAC-i̲eng.indb 31

2009/07/09 16:13:27

2009/07/09 16:13:27

Summary of Contents for OU-PSINV-25HR

Page 75: ...75 ...