44

10. TEST RUN

10-1. Preparing for Test Run

●

Before attempting to start the air conditioner, check the

following:

(1) All loose matter is removed from the cabinet especially

steel filings, bits of wire, and clips.

(2) The control wiring is correctly connected and all electrical

connections are tight.

(3) The protective spacers for the compressor used for

transportation have been removed. If not, remove them

now.

(4) The transportation pads for the indoor fan have been

removed. If not, remove them now.

(5) The power has been supplied to the unit for at least 5

hours before starting the compressor. The bottom of

the compressor should be warm to the touch and the

crankcase heater around the feet of the compressor should

be hot to the touch.

(Fig. 10-1)

(Power must be turned ON at least

5 hours before attempting test run)

Power mains switch

ON

Fig. 10-1

(6) Both the gas and liquid tube service valves are open. If

not, open them now. (Fig. 10-2)

Liquid tube

Gas tube

Fig. 10-2

(7) Request that the customer be present for the test run.

Explain the contents of the instruction manual, and then

have the customer actually operate the system.

(8) Be sure to give the instruction manual and warranty

certificate to the customer.

(9) When replacing the control PCB, be sure to make all the

same settings on the new PCB as were in use before

replacement.

The existing EEPROM is not changed, and is connected to

the new control PCB.

■

4WK, C, D Types

10-2. Caution

●

This unit may be used in a single-type refrigerant

system where 1 outdoor unit is connected to 1 indoor

unit, and also in a system where 1 outdoor unit is

connected to multiple indoor units (maximum 4).

* If multiple indoor units are used, also refer to “10-8. System

Control.”

●

The indoor and outdoor unit control PCB utilizes

a semiconductor memory element (EEPROM). The

settings required for operation were made at the time of

shipment.

Only the correct combinations of indoor and outdoor

units can be used.

●

This test run section describes primarily the procedure

when using the wired remote controller.

10-3. Test Run Procedure

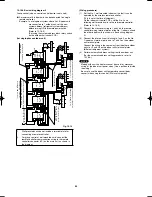

YES

YES

YES

NO

NO

NO

Recheck the items to check

before the test run.

Check the combination (wiring) of

indoor and outdoor units.

(See 10-8-1 to 5)

(See 10-4)

Is system “single-type”?

(1 indoor unit is connected

to 1 outdoor unit and remote

controller)

Is group control with

multiple outdoor units used?

Turn ON the indoor and

outdoor power.

Indicate (mark) the

combination number.

(See 10-8-5)

Automatic

address

Set the remote controller to

“test run”.

(See 10-5)

Can

operation be

started?

Return the remote controller

to normal control.

Turn ON the

indoor and

outdoor power.

(Automatic

Address)

(See 10-8-3)

Setting the Outdoor

Unit System

Address

Set the outdoor

unit system

address.

(See 10-8-4)

Automatic Address

Setting

Use the remote

controller to

perform automatic

address setting.

Refer to “Table of Self-

Diagnostic Functions”

to check the system.

In addition, refer to 10-

8-1 to 5 and correct

any items that need to

be corrected.

Note: Check the indoor-side

drainage.

(*1) Required for

simultaneous-operation

multi systems and for

group control.

(*1)

Fig. 10-3

Airwell̲PAC-i̲eng.indb 44

Airwell̲PAC-i̲eng.indb 44

2009/07/09 16:13:34

2009/07/09 16:13:34

Summary of Contents for OU-PSINV-25HR

Page 75: ...75 ...