Page

40

of

125

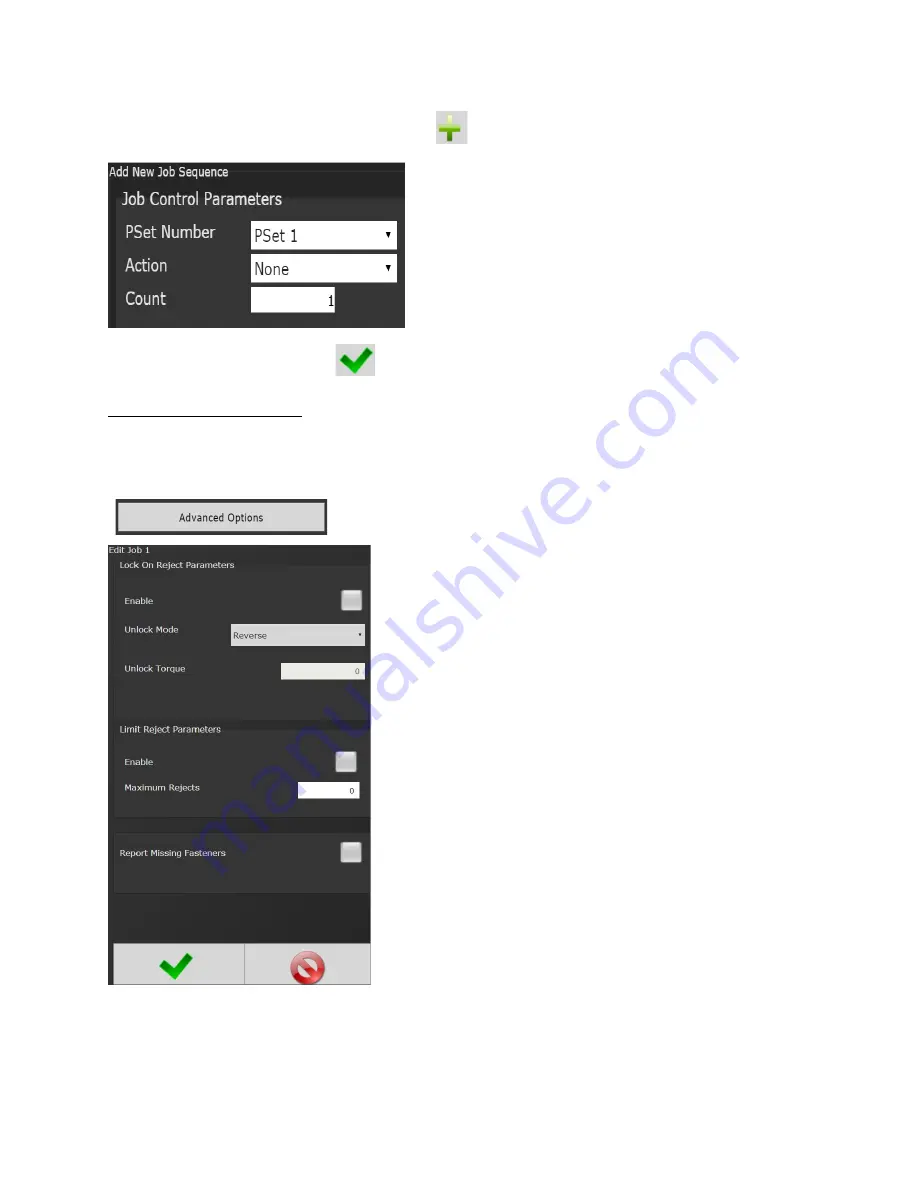

After appropriate values are entered, press

to go to Add New Job Sequence screen.

PSet Number

: Choose any current PSet already

configured in controller.

Action:

•

None:

Will stay in current sequence.

•

Next:

will advance to next sequence set up after

count is reached.

•

Count:

Fastener number required to complete

sequence.

Once values are entered press

two times to return to Job screen

4.3.2 Advanced Options

Lock on Reject:

When enabled this prevents tool from starting a new rundown if the result of the

last rundown was a reject. Tool remains locked until one of the four Unlock Mode conditions

above are satisfied.

Unlock Mode:

Reverse:

Running tool in disassembly mode.

Reverse and Throttle:

Running tool in disassembly mode.

Reverse and Unlock Torque:

Exceeding “Unlock Torque”

while tool is in the disassembly direction (Backing off a

rejected fastener).

MFB:

Pressing MFB button on tool (Regardless of MFB

configuration).

Unlock Torque:

If Unlock Mode is set to “Reverse and

Unlock Torque”, this torque value must be exceeded

when the tool is in the disassembly direction in order to

unlock the tool.

Limit Reject Parameters

Enable/Disable

Maximum:

Rejects Enter # of rejects allowed

Report Missing Fasteners:

Add an option to each JOB that would allow us to report

any missing fasteners. When it is set the controller will

report an NOK rundown for each fastener that is defined

in the JOB but has not been ran. These NOK results will be reported whenever a new job is

started AND the prior JOB is incomplete.

These generated NOK results are treated like any other fastening. They are displayed on the run

screen, stored in the results and transmitted on all protocols.