01

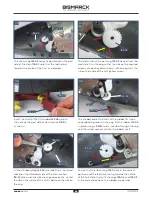

. ASSEMBLING THE RUDDERS AND COGS

01

02

123-02

PWM

123-03

123-04

123-05

123-01

123-06

123-07

123-03

123-05

118-01

118-01

1

2

3

STAGE 123

THE TWIN RUDDERS

COMPONENTS CHECKLIST

Fit the port cog

123-03

(marked L) on the raised socket

on the port side of the stern

118-01

, as indicated. Note

the position of the three ribs: rib

1 (on the inside of the

hull) sits between the ribs

2 and 3 on the cog.

Position the cog support

123-05

on the hull assembly

so that it sits on the raised screw sockets in the stern

section

118-01

.

123-01:

Motor for the rudders

123-02:

Large cog

123-03:

Port cog (L)

123-04:

Starboard cog (R)

123-05:

Cog support

123-06:

Two rudders

123-07:

Cable label (D1)

PWM:

Five 2 x 4mm PWM

screws

27

27

AGORA

MODELS

PB

AGORA

MODELS