9

Installing the platform

About installing the AssayMAP head

AssayMAP Bravo Platform Installation Guide

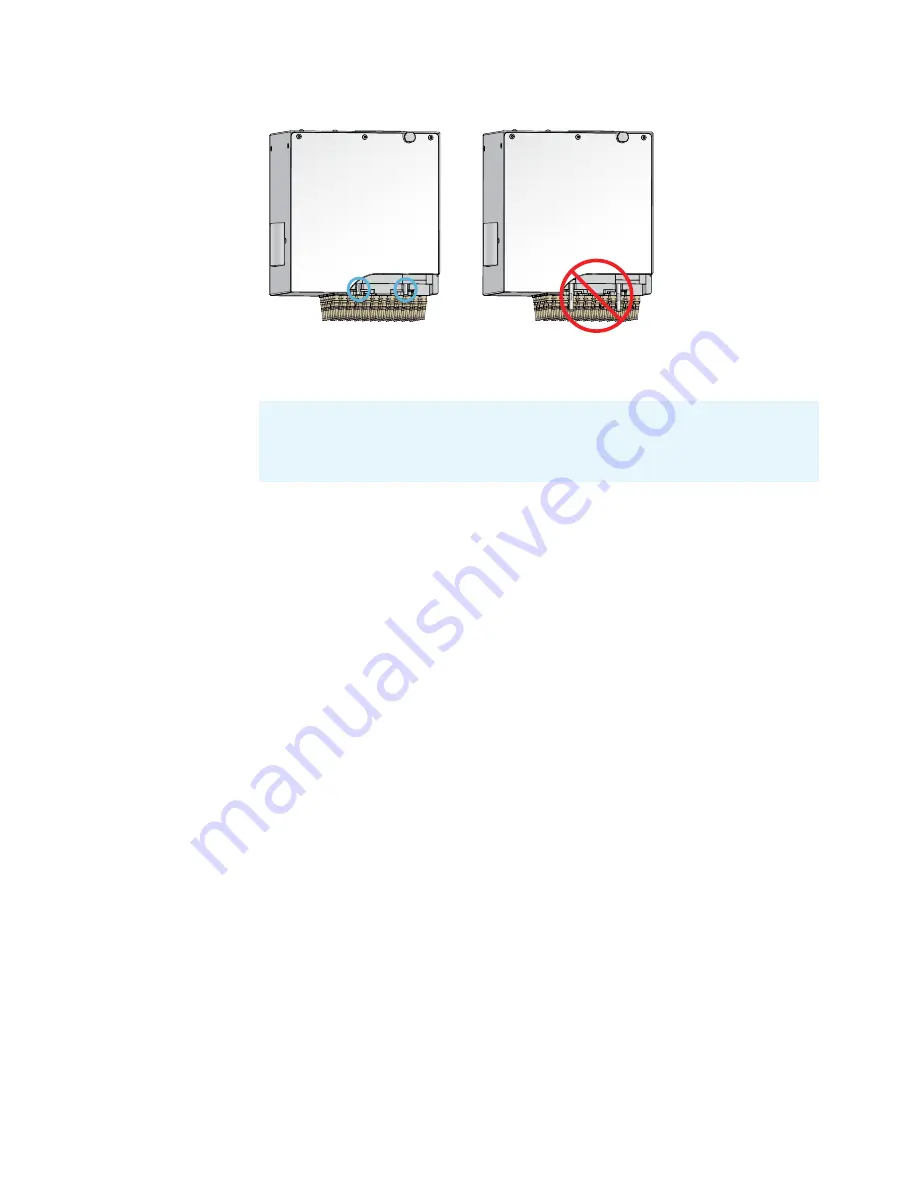

Figure

Bravo 96AM Head with tip-box stripper pins retracted (left) and extended (right)

Retracting the tip-box stripper pins

To retract the tip box stripper pins:

1

Place the Bravo 96AM Head upside down on a stable surface, so that the

probes are facing up and the front of the 96AM Head (logo side) is facing

you.

If directional arrows appear on the pins, gently rotate the pins so that the

arrows are facing you.

2

Insert the end of a 2- mm hex wrench into the head of one of the pins, and

very gently push the pin down into the pipette head until you feel the pin

stop.

Verify that the pin is properly seated. If the pin has an arrow, the square

end of the arrow should disappear or be barely visible.

IMPORTANT

If the pin hits a stop before it retracts completely, the pin

locking mechanism is above instead of below the locking dowel. While

removing any downward pressure on the pin head, gently rotate the pin

in quarter- turn increments until you feel the pin drop into the seated

position.

3

When the pin is properly seated, rotate it counterclockwise no more than

180

°

until it locks.

4

Repeat this procedure for the other pins.

CAUTION

If you apply too much force when pressing down or rotating the pin to retract it,

the locking mechanism at the tip of the pin can bend or break. A damaged pin cannot lock in

the retracted position. Use only gentle pressure to push down and rotate the pin to lock it into

place.