©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932

l&M V 6584 R16 sec1

www.ascovalve.com

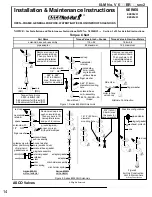

Remove red cap or retainer from top of solenoid base

sub-assembly. For 3-way construction with pipe adapter

(Figure 3), remove pipe adapter, nameplate and solenoid.

Omit steps 4 and 5.

Push down on solenoid: Then using a suitable screwdriver,

insert blade between solenoid and nameplate/retainer. Pry

up slightly and push to remove. NOTE: Series 8202O/H

solenoids have a spacer between the nameplate/retainer and

solenoid.

Remove solenoid from solenoid base sub-assembly.

Reassemble in reverse order of disassembly. Use exploded

views for identification and placement of parts.

Torque pipe adapter to 90 inch-pounds maximum [10,2 Nm

maximum]. Then make up piping or tubing to pipe adapter

on solenoid.

3.

4.

5.

6.

7.

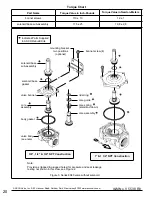

Disassembly and Reassembly of Solenoids

Remove solenoid, see

Solenoid Replacement.

Remove spring washer from solenoid base sub-assembly.

For 3-way construction, remove pipe adapter and plugnut

gasket.

1.

2.

Unscrew solenoid base sub-assembly from valve body.

Remove internal solenoid parts for cleaning or replacement.

Use exploded views for identification and placement of

parts.

If the solenoid is part of a valve, refer to basic valve instal-

lation and maintenance instructions for further disassembly.

Torque solenoid base sub-assembly and adapter to 175±25

in-lbs [19,8±2,8 Nm].

3.

4.

5.

6.

ORDERING INFORMATION FOR ASCO

SOLENOIDS

When Ordering Solenoids for ASCO Solenoid

Operators or Valves, order the number stamped on

the solenoid. Also specify voltage and frequency.

lnstallation & Maintenance Instructions

1

3

Summary of Contents for E-STOP09

Page 28: ...28...