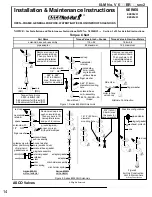

lnstallation & Maintenance Instructions

SERIES

8003G/H

8007G/H

8202G/H

l&M V 6584 R16 sec1

OPEN-FRAME, GENERAL PURPOSE, WATERTIGHT/EXPLOSIONPROOF SOLENOIDS

ASCO® solenoid valves with design change letter

“G” or “H’’ in the catalog number ( ex. 821 0G I) have

an epoxy encapsulated ASCO® Red Hat II® solenoid.

This solenoid replaces some of the solenoids with

metal enclosures and open frame constructions. Follow

these installation and maintenance instructions if your

valve or operator uses this solenoid.

See separate instructions for basic valve.

* DIN Plug Connector Kit No. K236034:

Use this kit

only for solenoids with DIN terminals. The DIN plug

connector kit provides\a two pole with grounding con-

tact DIN Type 43650 construction (See Figure 6).

OPERATION

Series 8003G/H and 8007G/H - When the solenoid is energized,

the core is drawn into the solenoid base sub-assembly.

IMPORTANT: When the solenoid is de-energized, the initial

return force for the core, whether developed by spring,pres-

sure, or weight, must exert a minimum force to overcome re-

sidual magnetism created by the solenoid. Minimum return

force for AC construction is 11 ounces, and 5 ounces for DC

construction.

Series 8202G/H - When the solenoid is energized, the disc

holder assembly seats against the orifice. When the solenoid is

de-energized , the disc holder assembly returns.

IMPORTANT:

Initial return force for the disc or disc holder assembly,

whether developed by spring, pressure, or weight, must

exert a minimum force to overcome residual magnetism

created by the solenoid. Minimum return force is 1 pound, 5

ounces.

INSTALLATION

Check nameplate for correct catalog number, service, and watt-

age. Check front of solenoid for voltage and frequency.

A WARNING: Electrical hazard from the acces-

sibility of live parts. To prevent the possibility of

death, serious injury or property damage, install

the open • frame solenoid in an enclosure.

FOR BLACK ENCLOSURE TYPES 7 AND 9 ONLY

ACAUTlON: To prevent fire or explosion, do not install

solenoid and/or valve where ignition temperature of hazard-

ous atmosphere is less than 165’C. On valves used for steam

service or when a class “H” solenoid is used, do not install

in hazardous atmosphere where ignition temperature is less

than 180’C. See nameplate/ retainer for service.

NOTE:

These solenoids have an internal non-resetable thermal

fuse to limit solenoid temperature in the event that extraordinary

conditions occur which could cause excessive temperatures.

These conditions include high input voltage, a jammed core,

excessive ambient temperature or a shorted solenoid, etc. This

unique feature is a standard feature only in solenoids with black

explosionproof/dust-ignitionproof enclosures (Types 7 & 9).

A CAUTION: To protect the solenoid valve or operator,

install a strainer or filter, suitable for the service involved

in the inlet side as close to the valve or operator as possible.

Clean periodically depending on service conditions. See

ASCO Series 8600 and 8601 for strainers.

DESCRIPTION

Catalog numbers 8003G/H, 8007G/H and 8202G/H and are ep-

oxy encapsulated pull-type soleoids. The green solen01d with

lead wires and 1/2 conduit connection is designed to meet En-

closure Type !-General Purpose, Type 2-Dripproof, Types 3 and

3S-Raintight, and Types 4 and 4X-Watertight. The black solenoid

on catalog numbers prefixed “EF” or “EV” is designed to meet

Enclosure Types 3 and 3S-Raintight, Types 4 and 4X-Watertight,

Types 6 and 6P-Submersible, Type7, Explosionproof Class I,

Division! Groups A, B, C, & D and Type 9, -Dust-lgnitionproof-

Class II, Division! Groups E, F & G. The Class II, Groups F &

G Dust Locations designation is not applicable for solenoids or

solenoid valves used for steam service or when a class “H” so-

lenoid is used. See Temperature Limitations section for solenoid

identification and nameplate/ retainer for service. When installed

just as a solenoid and not attached to an ASCO valve, the core

has a 0.250-28 UNF-2B tapped hole, 0.38 or 0.63 minimum full

thread.

NOTE:

Catalog number prefix “EV” denotes stainless steel

construction.

Solenoid catalog numbers 8202G/HI, 8202G/H3, 8202G/ H5 and

8202G/H7 are epoxy encapsulated push-type, reverse-acting so-

lenoids having the same enclosure types as previously stated for

Catalog numbers 8003G/Hl and 8003G/ H2. 8007G/H are 3-way

solenoid operators with a pipe port or adapter, exhaust protector

or vent at the top of the solenoid base sub-assembly.

Series 8003G/H, 8007G/H and 8202G/H solenoids are avail-

able in:

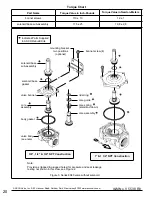

Open-Frame Construction:

The green solenoid may be

supplied with 1/4” spade, screw or DIN terminals. (Refer to

Figure 4)

Panel Mounted Construction:

These solenoids are specifi

-

cally designed to be panel mounted by the customer. Refer to

Figures specified in this l&M and the section on Installation

of Panel Mounted Solenoid for details.

Optional Features For Type 1 • General Purpose Construction

Only

Junction Box: This junction box construction meets Enclosure Types

2, 3, 3S, 4, and 4X. Only solenoids with 1/4” spade or screw terminals

may have a junction box. The junction box provides a 1/2” conduit

connection, grounding and spade or screw terminal connections within

the junction box. (See Figure 5)

- SERVICE NOTICE-

l&M V 6584 R16 sec1

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932

www.ascovalve.com

10

Summary of Contents for E-STOP09

Page 28: ...28...