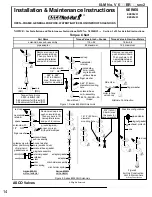

MODEL: T101R

24 HR DIAL TIME SWITCH (SPSTI

TYPE 3R RAINPROOF ENCLOSURE

SUITABLE FOR POOL EQUIPMENT CONTROL IF

INSTALLED 5FT. OR MORE FROM EDGE OF POOL.

40 A RESISTIVE, INDUCTIVE, TUNGSTEN

OR 1000 VA PILOT DUTY 120/208/240 VAC;

2 HP (24 FLA) - 120 VAC; 5 HP (28 FLA) - 240 VAC

16 A ELECTRONIC BALLAST 277 VAC

�• LR3

.----

730

-----,

C

US

UL

HOLOGRAM

LABEL

A

WARNING

_.....,

____________________ _

Risk of Fire or Electric Shock

• Disconnect power at the circuit breaker(s) or disconnect switch(es) before installing or servicing.

• Installation and/or wiring must be in accordance with national and local electrical code requirements.

• Use wires rated at least 90

°

C - COPPER conductors ONLY.

• For outdoor locations, raintight, or wet location, conduit hubs that comply with requirements of

UL514B (standard for fittings for conduit and outlet boxes) are to be used.

• Replace plastic insulator covering terminals before powering ON.

• KEEP DOOR CLOSED AT ALL TIMES when not servicing.

A

AVERTISSEMENT

Risque d'incendie ou de choc electrique

• Utiliser des fils classes 90

°

c minimum - Conducteurs en CUIVRE UNIQUEMENT.

• Pour les emplacements exterieurs, etanches

a

la pluie ou les emplacements mouilles, des entrees de

conduit qui sont conformes aux exigences de UL514B (norme pour les pieces de fixation pour conduit

et boites de sortie) doivent etre utilisees .

.,............. • Rotate timer dial clockwise only.

• Do not move the clock hands on the timer. Moving the clock hands can damage the timer.

CLOCK MOTOR: 120 VAC, 60 HZ.

CLOCK MOTOR VOLTAGE AND CYCLE MUST BE AS SPECIFIED.

TO

ORDER REPLACEMENT, INDICATE PART NO. (WG--) ON MOTOR COVER.

TIME

DIAL

WIRING

DIAGRAM

D.

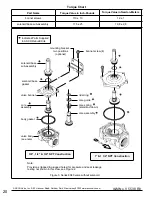

WIRING INSTRUCTIONS: Remove 1/2 inch of insulation from wire ends. Tighten terminal screws firmly

(2-18 in- lbs). Use solid or stranded COPPER conductors only. May use two wires of the same size and type.

��:;�:

�ii

,:i't

75•c INSu��g�H�· MOTOR

---....

PRESSURE PLATE

WIRE SIZE (AMP) ATION

(AWG)

TEMP(

°

C)

"V-■

--TERMINAL SCREW

SINGLE PHASE

120V.

240V.

240V.

14 15

90

12

20 90

10

30 90

8

40 90

1/2

1

2

2

21/2 N/A

3

5

PROGRAMMING INSTRUCTIONS

N/A

1. TO SET "ON" AND "OFF" TIMES: Hold trippers against edge of CLOCK-

DIAL, pointing to time (AM or PM) when ON and OFF operations are desired,

tighten tripper screws firmly. For additional tripper pairs on CLOCK-DIAL order

156T1978A.

2. TO SET TIME-OF-DAY: Pull CLOCK-DIAL outward. Turn in either direction and

align the exact time-of-day on the CLOCK-DIAL (the time now, when switch is

being put into operation) to the pointer. DO NOT MOVE POINTER.

OPERATING INSTRUCTIONS

• TO OPERATE SWITCH MANUALLY: Move MANUAL LEVER below CLOCK-DIAL

left or right as indicated by arrows. This will not effect next operation.

• IN CASE OF POWER FAILURE, reset CLOCK-DIAL to proper time-of-day. See

programming instructions.

INTERMATIC INCORPORATED

SPRING GROVE, ILLINOIS 60081-9698

154--01994

8

Summary of Contents for E-STOP09

Page 28: ...28...