EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that the product

described under “Technical Data” fulfills all the relevant

provisions of the directives 2011/65/EU (RoHs), 2014/30/

EU, 2006/42/EC, 2000/14/EC, 2005/88/EC, and the following

standards have been used:

EN 60745-1:2009+A11:2010

EN 60745-2-13:2009+A1:2010

EN ISO 3744:2010

EN 55014-1:2006+A1:2009+A2:2011

EN 55014-2:2015

EN 50581:2012

Measured sound power level 94.2 dB(A)

Guaranteed sound power level 99 dB(A)

Conformity assessment method to Annex V Directive 2000/14/

EC amended by 2005/88/EC

Notified body, 0197 TÜV Rheinland LGA Products GmbH;

Tillystraße 2 D - 90431 Nürnberg, Germany has carried out

EC type approval, and the certificate number is : BM 50367224

0001

Winnenden, 08 March 2017

Alexander Krug

Managing Director

Authorised to compile the technical file.

Techtronic Industries GmbH

Max-Eyth-Straße 10,

71364 Winnenden,

Germany

Summary of Contents for ACS183060

Page 1: ...ACS18B30 ACS183060 ...

Page 2: ...2 2 ENGLISH 1 2 3 Picture section with operating description and functional description 4 ...

Page 4: ...4 4 20 19 12 10 ...

Page 5: ...5 5 START STOP 8 16 21 13 14 23 15 ...

Page 6: ...6 6 12 13 6 9 10 11 8 7 ...

Page 7: ...7 7 17 18 16 15 14 1 2 3 4 5 ...

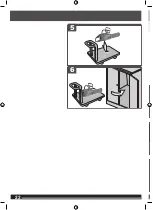

Page 8: ...8 8 Remove the battery pack before starting any work on the machine 1 click 2 1 2 ...

Page 9: ...9 9 75 100 0 25 50 75 25 50 ...

Page 10: ...10 10 2 1 3 ...

Page 11: ...11 11 5 4 6 Only finger tighten APPROX 4 5 5 mm ...

Page 12: ...12 12 FLATS APPROX 4 5 5 mm 2 3 1 ...

Page 13: ...13 13 2 3 1 ...

Page 14: ...14 14 1 2 3 START STOP ...

Page 15: ...15 15 BRAKE ON BRAKE OFF ...

Page 16: ...16 16 2 3 1 ...

Page 17: ...17 17 5 6 7 4 Only finger tighten ...

Page 18: ...18 18 FLATS APPROX 4 5 5 mm 8 ...

Page 19: ...19 19 2 1 ...

Page 20: ...20 20 ...

Page 21: ...21 21 2 3 1 4 ...

Page 22: ...22 22 6 5 ...

Page 23: ...23 23 Figure 1 Figure 6 Figure 2 Figure 3 Figure 5 1 3 2 5 cm 2 in 5 cm 2 in Figure 4 ...

Page 33: ...uct ant 30 ing 14 bH out 224 ...

Page 34: ......

Page 35: ......