31

31

WARNING! Remove the battery before adjustment,

maintenance or cleaning. Failure to do so could result in

serious personal injury.

You may only make adjustments or repairs described in this manual.

For other repairs, contact the authorised service agent.

Consequences of improper maintenance may cause the chain brake

and other safety features to not function correctly, thus increasing

the potential for serious injury. Keep your chainsaw professionally

maintained and safe.

Sharpening the chain safely is a skilled task. Therefore, the

manufacturer strongly recommends that a worn or dull chain

is replaced with a new one, available at your authorised service

centre. The part number is available in the product specification

table in this manual.

Follow instructions for lubricating and chain tension checking and

adjustment.

After each use, clean the product with a soft dry cloth.

Check all nuts, bolts, and screws at frequent intervals for security

to ensure the product is in safe working condition. Any part that is

damaged should be properly repaired or replaced by an authorised

service centre.

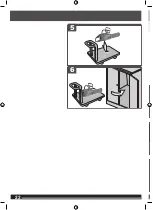

Replacing the guide bar and saw chain

See pages 16 - 18.

Make sure to remove the battery pack from the product. Wear

protective gloves.

Remove the bar mounting nuts using the combination wrench

provided.

Remove the chain cover.

Remove the bar and saw chain from the product.

Put the new chain in the correct direction onto the bar and make

sure that the drive links are aligned in the bar groove.

Attach the bar to the chain saw and loop the chain around the drive

sprocket.

Replace the chain cover and bar mounting nuts.

Finger-tighten the bar mounting nuts. The bar must be free to move

for chain tension adjustment.

Adjust the chain tension. Refer to the “Adjusting chain tension”

section.

Hold the tip of the guide bar up and tighten the bar mounting nuts

securely.

WARNING! A dull or improperly sharpened chain can

cause excessive motor speed during cutting which may result

in severe motor damage.

WARNING! Improper chain sharpening increases the

potential of kickback.

WARNING! Failure to replace or repair a damaged chain

can cause serious injury.

WARNING! The saw chain is sharp. Always wear protective

gloves when performing maintenance to the chain.

Inspecting and cleaning the chain brake

Always keep the chain brake mechanism clean by lightly brushing

the linkage free from dirt.

Always test the chain brake performance after cleaning. Refer to

“Checking and operating the chain brake” section in this manual for

additional information.

MAINTENANCE SCHEDULE

Daily check

Bar lubrication

Before each use

Chain tension

Before each use and

frequently

Chain sharpness

Before each use, visual

check

For damaged parts

Before each use

For loose fasteners

Before each use

Chain brake function

Before each use

Inspect and clean

Bar

Before each use

Complete saw

After each use

Chain brake

Every 5 hours of operation

Spare parts

Oregon

Chain

90PX045X

Bar

124MLEA041

Exploded view

If needed, an exploded view of the tool can be ordered. Please

state the machine type printed as well as the six-digit No. on the

label and order the drawing at your local service agents or directly

at: Techtronic Industries GmbH, Max-Eyth-Straße 10, 71364

Winnenden, Germany.

BATTERIES

Battery packs which have not been used for some time should be

recharged before use.

Temperatures in excess of 50°C (122°F) reduce the performance

of the battery pack. Avoid extended exposure to heat or sunshine

(risk of overheating).

The contacts of chargers and battery packs must be kept clean.

For an optimum life-time, the battery packs have to be fully charged,

after used.

To obtain the longest possible battery life remove the battery pack

from the charger once it is fully charged.

For battery pack storage longer than 30 days:

Store the battery pack where the temperature is below 27°C and

away from moisture.

Store the battery packs in a 30% - 50% charged condition.

Every six months of storage, charge the pack as normal.

TRANSPORTING LITHIUM BATTERIES

Lithium-ion batteries are subject to the Dangerous Goods

Legislation requirements.

Transportation of those batteries has to be done in accordance with

local, national and international provisions and regulations.

■

The user can transport the batteries by road without further

requirements.

■ Commercial transport of Lithium-Ion batteries by third parties is

subject to Dangerous Goods regulations. Transport preparation

and transport are exclusively to be carried out by appropriately

trained persons and the process has to be accompanied by

corresponding experts.

When transporting batteries:

■

Ensure that battery contact terminals are protected and

insulated to prevent short circuit.

■

Ensure that battery pack is secured against movement within

packaging.

■ Do not transport batteries that are cracked or leak.

Check with forwarding company for further advice

SYMBOLS

Safety alert

Read and understand all instructions before

operating the product, follow all warnings and

safety instructions.

Wear eye, ear and head protection.

Wear non-slip safety footwear when using the

product.

Wear non-slip, heavy duty gloves.

Wear eye and face protection.

Wear upper body protection.

Wear leg protection.

Beware of chain saw kickback and avoid contact

with bar tip.

Do not expose to rain or damp condition.

Moving direction of the chain.

(Marked under the chain cover)

Hold and operate the saw properly with both

hands.

Do not operate the saw using only one hand.

Remove the battery pack before starting any work

on the product.

Do not burn used battery packs.

Never charge a damaged battery pack. Replace

with a new one.

Summary of Contents for ACS183060

Page 1: ...ACS18B30 ACS183060 ...

Page 2: ...2 2 ENGLISH 1 2 3 Picture section with operating description and functional description 4 ...

Page 4: ...4 4 20 19 12 10 ...

Page 5: ...5 5 START STOP 8 16 21 13 14 23 15 ...

Page 6: ...6 6 12 13 6 9 10 11 8 7 ...

Page 7: ...7 7 17 18 16 15 14 1 2 3 4 5 ...

Page 8: ...8 8 Remove the battery pack before starting any work on the machine 1 click 2 1 2 ...

Page 9: ...9 9 75 100 0 25 50 75 25 50 ...

Page 10: ...10 10 2 1 3 ...

Page 11: ...11 11 5 4 6 Only finger tighten APPROX 4 5 5 mm ...

Page 12: ...12 12 FLATS APPROX 4 5 5 mm 2 3 1 ...

Page 13: ...13 13 2 3 1 ...

Page 14: ...14 14 1 2 3 START STOP ...

Page 15: ...15 15 BRAKE ON BRAKE OFF ...

Page 16: ...16 16 2 3 1 ...

Page 17: ...17 17 5 6 7 4 Only finger tighten ...

Page 18: ...18 18 FLATS APPROX 4 5 5 mm 8 ...

Page 19: ...19 19 2 1 ...

Page 20: ...20 20 ...

Page 21: ...21 21 2 3 1 4 ...

Page 22: ...22 22 6 5 ...

Page 23: ...23 23 Figure 1 Figure 6 Figure 2 Figure 3 Figure 5 1 3 2 5 cm 2 in 5 cm 2 in Figure 4 ...

Page 33: ...uct ant 30 ing 14 bH out 224 ...

Page 34: ......

Page 35: ......