Advanced Air UK Ltd

Burrell Way

Thetford

Norfolk IP24 3QU

Tel: 01842 765657

Email: [email protected]

2530 CE Series

Smoke Fire Damper

Due to continuous product development Advanced

(U.K.) Ltd reserves the right to change any

information without prior notice

Date

Issue

Sheet

Spec Number

April 2018

C

30 of 34

TS2530CE-01

G:\PRODUCTS\DMP - 2500 Series\05 Product Data\2530\Tech Sub\2530CE\TS2530CE-01 Technical Sub Rev C.docx

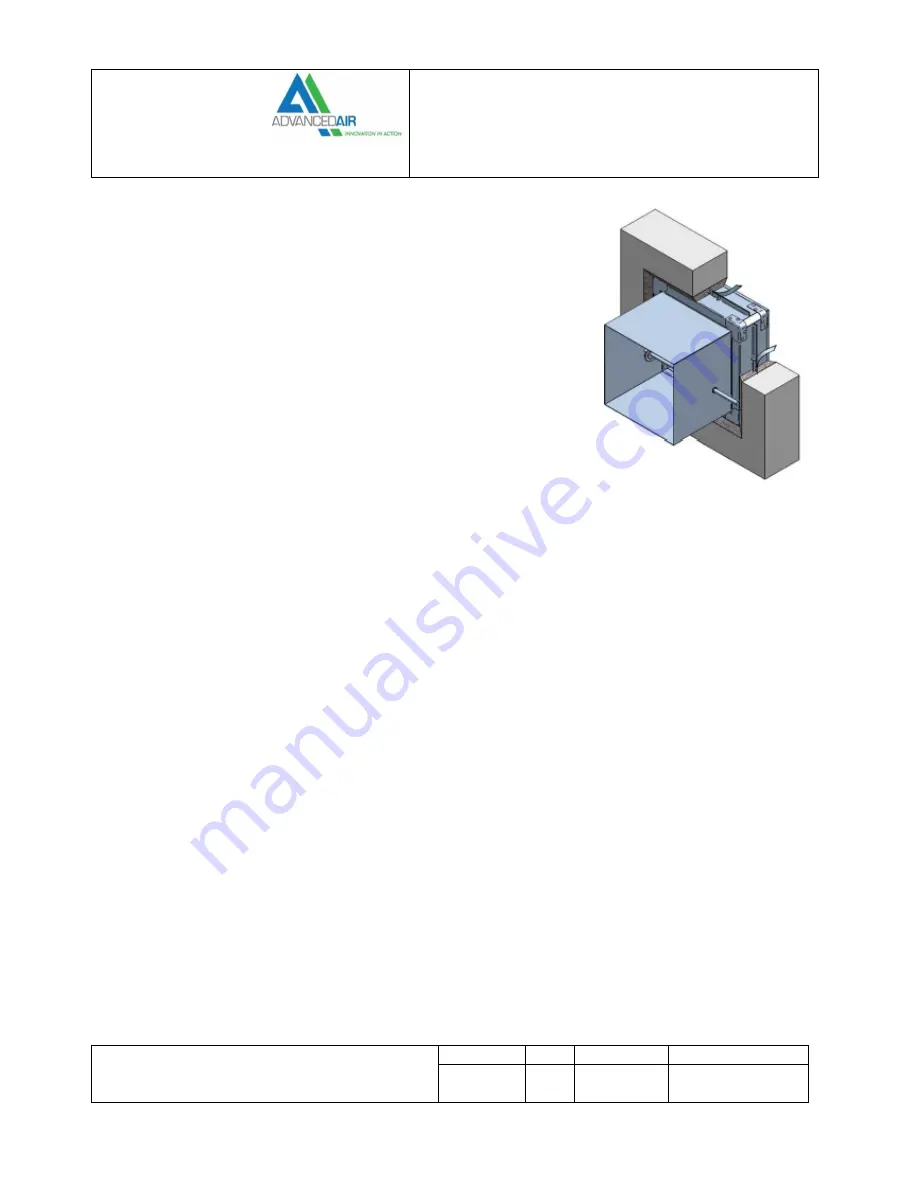

Blockwork wall HEVAC frame

Classification

E120 (ve i↔o)S

Pre Installation Notes

1.

Ensure that the damper is kept in a clean dry environment.

2.

Remove all packaging and any transit ties and check that the damper frame and

blades are clean and free of any freight matter.

3.

Examine the assembly for distortion, denting or surface damage which could

inhibit the operation of the damper.

4.

Operate the damper blades in the appropriate mounting position. It is important

that the blades operate freely and without undue pressure being applied.

Installation Procedure

1.

Vertical builders work barrier to have an appropriately sized lintel to ensure an

opening clearance for the expansion frame.

2.

The opening in the wall must be cleaned, free of dust and any other contaminants which could impair the mortar

adhesion. A clearance gap 25mm (min) to 50mm (max) must be maintained around the expansion frame of the damper

(barrier contractor).

3.

The damper shall be fitted centrally in the wall opening.

4.

The tabs on the factory fitted galvanised steel expansion frame shall be bent out to tie the damper into the wall with the

penetration seal.

5.

The ‘Penetration Seal’ must have a structural and fire rated compatibility with both the barrier and the damper and have

sufficient strength to retain the fire damper within the wall in a fire situation. (4:1 mortar mix).

6.

The mortar mix will be applied up to the installation frame face, take care not to leave any air pockets in the mix.

7.

The ductwork connecting to the damper spigots must overlap by 40mm, leaving a 10mm clearance for any duct expansion

in a fire situation.

8.

All ductwork connections must be sealed with an approved ductwork sealer, and fixed with low resistance fixings such as

aluminium alloy rivets or nylon bolts.

9.

All connecting ductwork must be independently supported within 1m of the connections.

10.

An access cover should be fitted on the appropriate side of the barrier to enable inspections and maintenance work.