43

KOOLMASTER PP20-VS2 rev.00

KOOLMASTER PP20-VS2

14. TECHNICAL SPECIFICA-

TIONS

Type

KOOLMASTER PP20-

VS2

Main supply Fuse F1

4A, slow-blow

Mains supply/fre-

quency

85-250V, 50/60Hz

0-10V outputs 1-2

0-10Vdc, 30mA

source max.

Precision on 0-10V

outputs

±1 %

14Vdc output

14 VDC ±10%, regu-

lated, 250 mA max.

Variable outputs 1,2

230VAC, 10A Max,

1.5HP (230VAC) /

0.5HP (115VAC)

Alarm contact

150 mA, 24 Vac or

dc max.

Pot + output

3.0V, 20 mA max.

Potentiometer inputs

1-20 K pot., linear

RH input

4-20 mA

Outside RH input

0-2.5V DC

Temperature inputs

1K @ 77 °F (25 °C),

NTC

Relays 1-20

Dry contact

15 A RES, 50/60 Hz

16 FLA @ 120 VAC

(1HP, 746 W)

12 FLA @ 240 VAC

(2HP, 1490 W)

Housing

IP54, plastic casing

Operating temperature

32 to 104°F (0 to

40 °C)

Storage temperature

5 to 122 °F (-15 to

50 °C)

Ambient relative

humidity

max. 95%

Pollution degree

2

Altitude

Up to 2000m

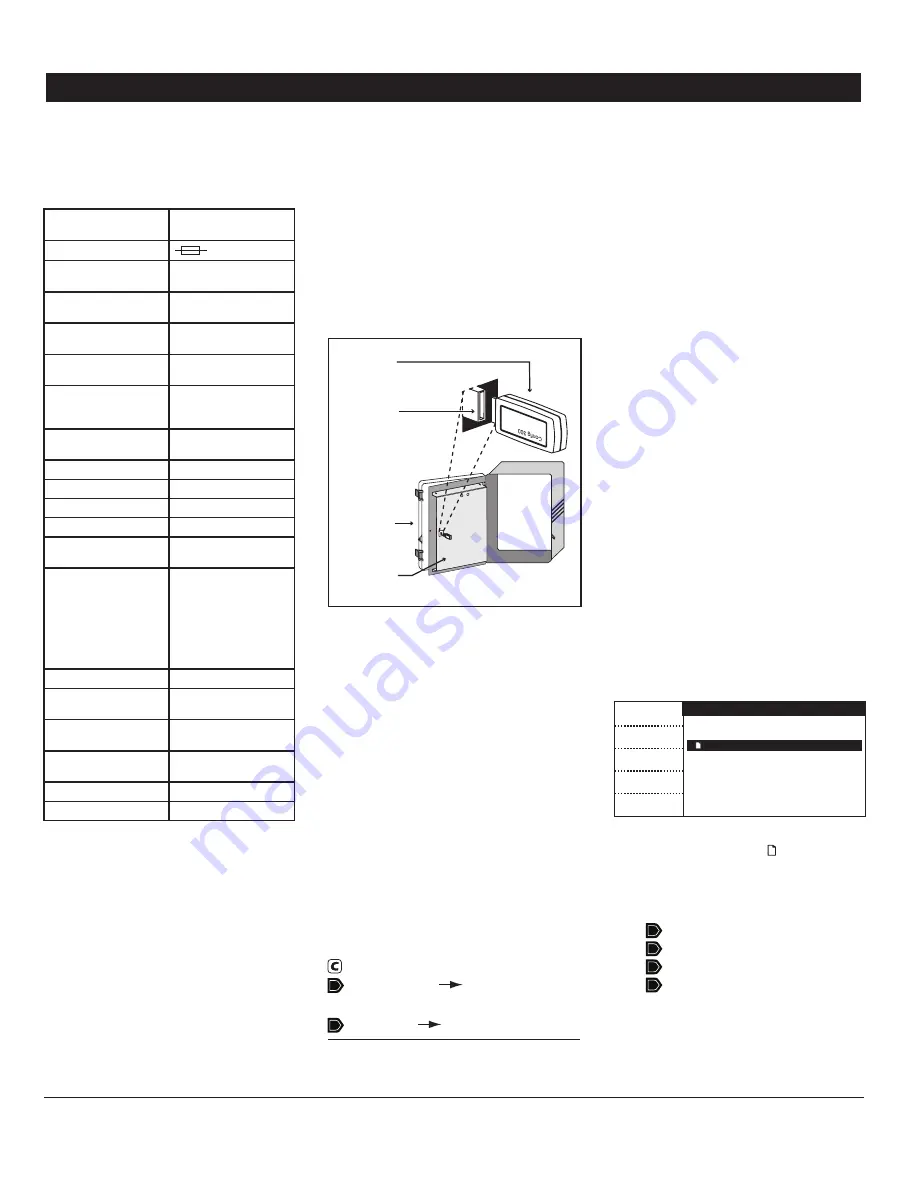

15. MEMORY CARD

Principle of Operation

15.1.

The memory card allows you to upgrade the

firmware or software of your controller with-

out loosing your parameter settings (firmware

and/or software upgrade). The card can also

be used to make a backup of your controller

settings or to copy these settings on another

controller of the same type.

Memory

Card

Connector

Cover

Front Panel

Various kind of files can be stored on the card:

configuration files (*.cfg files) and/or firmware

files (*.fir and *.bin files). Refer to section

14.3 to load or save a configuration file; refer

to section 14.4 to upgrade the firmware.

Accessing the Transfer

15.2.

Menu

Unscrew the screws located on the control-

1.

ler’s front panel then open the panel.

Insert the memory card in the connector

2.

located on the electronic board located on the

back of the front panel (see illustration).

Close the front panel then simultaneously

3.

press the up- and down-arrow keys for 3 sec-

onds to display the transfer menu.

Select the desired transfer menu:

4.

Current Conditions (Main Menu)

Memory Card

Controller

or

Controller

Memory Card

Configuration Transfer

15.3.

Configuration Files (*.cfg)

Configuration files are a set of instructions

that tells the controller what to do. These

files are divided into three parts:

1) Software (screen menus)

2) User data (parameter settings)

3) Potentiometer calibration

You can save your controller’s configuration

on the card or you can install a new configura-

tion into your controller. Note that it is now

possible to install a specific component of the

configuration without affecting the two other

components. For instance, you can upload

new controller software without affecting

your calibration & parameter settings.

Installing a New Configura-

15.3.1.

tion

The following procedure shows how to in-

stall a new configuration in your controller.

You can choose to install the whole new

configuration or to install a specific compo-

nent of it.

Access the transfer menu as explained in

1.

section 14.2 and select the

“Memory card to

controller”

menu.

Memory card to controller

Complete

Software

User Data

Pot. Calib

Exit

File_name.cfg

atm_0_7_30.bin

atm_0_7_30.fir

Select the proper configuration file (*.cfg)

2.

on the main screen. The icon indicates

which files can be used for the transfer.

Press the button that corresponds to the

3.

component(s) you want to install:

Complete (all components)

Software (screen menus)

User data (parameter settings)

Pot. Calib (inlet calib. settings)

Once the transfer is over, press Exit then

4.

remove the memory card from the connector.

Summary of Contents for Koolmaster PP20-VS2

Page 47: ......

Page 48: ...REV 00 M 890 00527 rev 00 ...