1 Operation Points and Startup

1-8

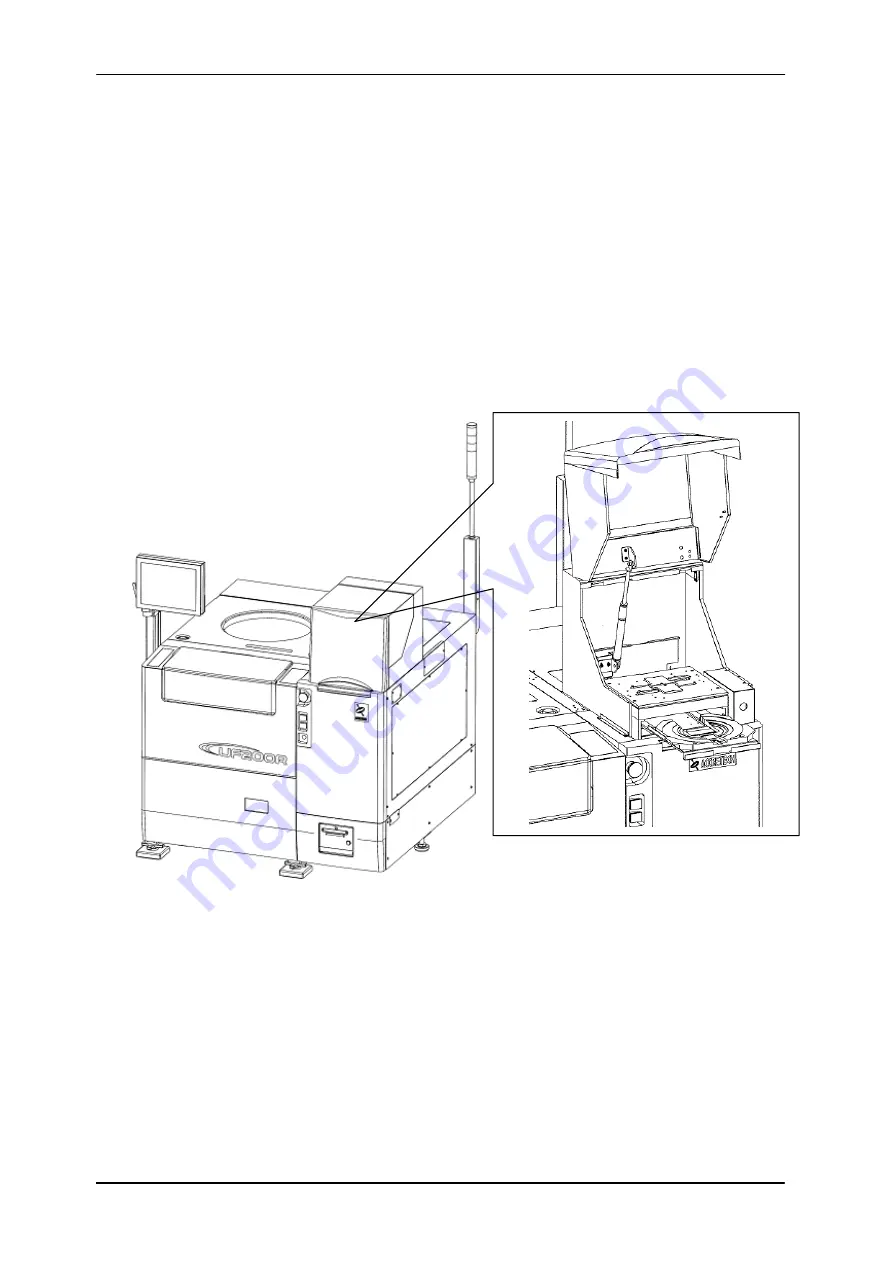

1.7 Loader

Unit

The cassette elevator in the loader unit supports 5-, 6- and 8-inch cassettes.

In UF200R, processing of new cassettes and locking/unlocking of the inspection tray are

performed with buttons on the display/touch panel.

Touch the “NEW CST” button to process new cassettes, and the “Lock/Unlock” button to

lock/unlock the inspection tray.

To set a wafer onto the inspection tray, or to remove the wafer from the inspection tray, first

unlock the inspection tray by touching the “Lock/Unlock” button. Then, pull out the tray as

shown below, and set or remove the wafer.