20

9.6

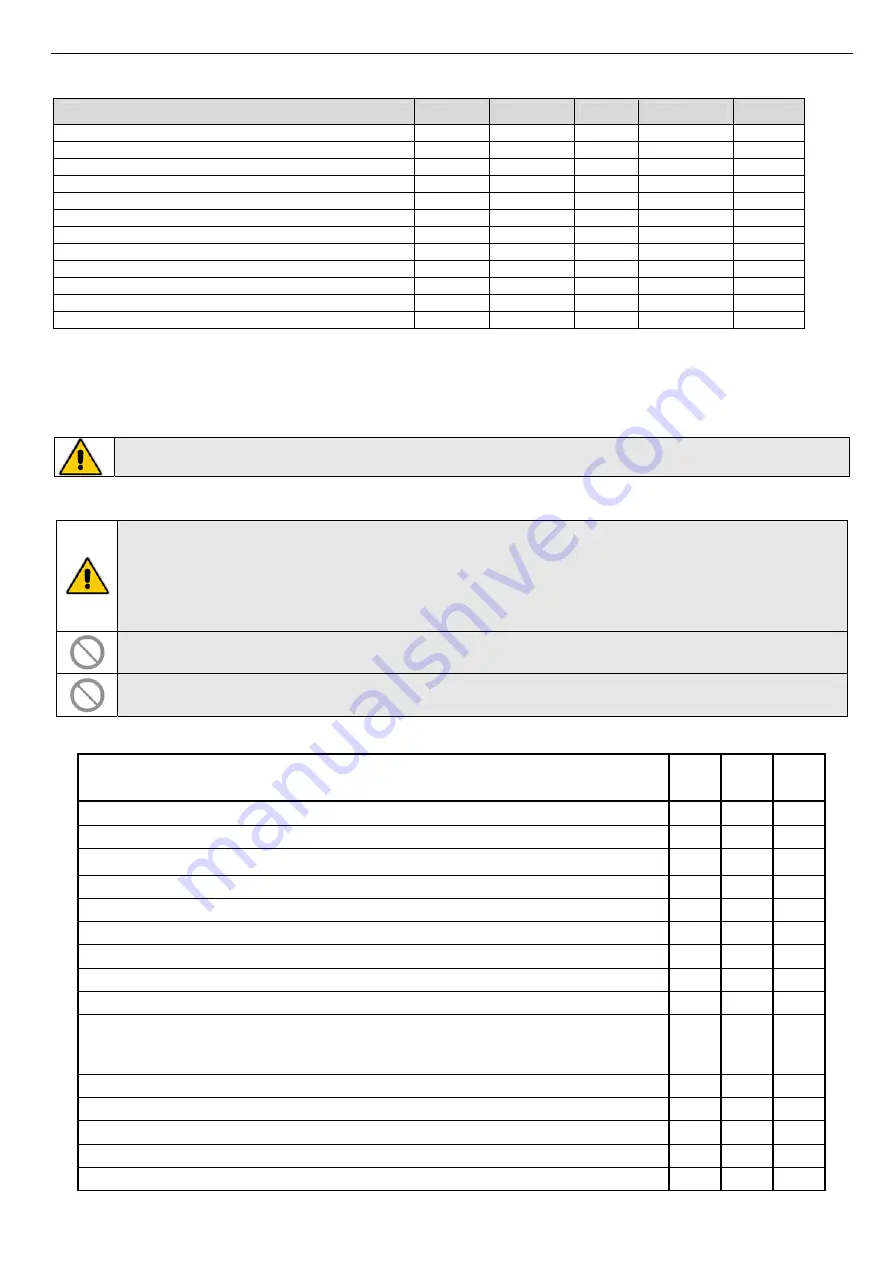

ALARMS

LIST

Error

description

Code

Compressor

Pump

Resistances

Fan

Inverter

hardware

malfunctioning

E75

OFF

OFF

Compressor’s

tension

too

high

E76

OFF

OFF

Power

supply

tension

out

of

bounds

E78

OFF

OFF

Compressor

not

power

supplied

E79

OFF

OFF

Inverter

time

out

malfunctioning

E80

OFF

OFF

Compressor

inlet

sensor

E63

OFF

OFF

OFF

OFF

Compressor

outlet

sensor

E64

OFF

OFF

OFF

OFF

High

pressure

transductor

E65

OFF

OFF

OFF

OFF

Low

pressure

transductor

E66

OFF

OFF

OFF

OFF

Outdoor

air

sensor

for

climate

adjust

E67

OFF

OFF

OFF

OFF

High

pressure

E01

OFF

OFF

Low

pressure

E02

OFF

OFF

10

SHUTDOWNS

FOR

LONG

PERIODS

•

Turn

off

all

the

indoor

terminal

units

of

the

users.

•

Close

the

water

faucet.

•

Turn

off

the

switch

QF

general

differential

to

OFF.

If

the

temperature

drops

below

freezing

point

(0°C)

there

is

serious

danger

of

frost:

providing

a

mixture

of

water

and

glycol

in

the

system,

otherwise

drain

the

water

system

and

the

hydraulic

circuits

of

the

heat

pump.

11

MAINTENANCE

AND

PERIODIC

CHECKS

WARNING:

All

the

operations

described

in

this

chapter

HAVE

TO

BE

CARRIED

OUT

BY

TRAINED

STAFF

ONLY.

Before

any

operation

or

before

entering

the

inner

components

of

the

unit,

be

sure

that

the

power

supply

is

disconnected.

The

compressor’s

heads

and

discharge

piping

are

usually

at

high

temperature

levels.

Be

very

careful

when

operating

in

their

surroundings.

Aluminium

coil

fins

are

very

sharp

and

can

cause

serious

wounds.

Be

very

careful

when

operating

in

their

surroundings.

After

servicing

operations,

re

‐

install

the

cover

panels,

and

fix

them

by

means

of

screws.

The

refrigerant

circuits

must

not

be

filled

with

refrigerant

gas

other

than

that

indicated

on

the

nameplate.

The

use

of

a

different

refrigerant

can

cause

severe

damage

to

the

compressor.

It

is

forbidden

to

use

refrigerant

oils

other

than

those

specified

in

this

manual.

The

use

of

different

oil

can

cause

serious

damage

to

the

compressor.

It

is

a

good

rule

to

carry

out

periodic

checks

in

order

to

verify

the

proper

operation

of

the

unit.

OPERATION

1

month

4

month

6

month

Filling

the

water

circuit.

x

Presence

of

bubbles

in

the

water

circuit.

x

Check

out

that

safety

and

control

devices

work

correctly

(indoor

and

outdoor

units)

x

Check

out

possible

oil

leakage

from

compressor

(outdoor

unit).

x

Check

out

possible

water

leakages

from

the

hydraulic

circuit

(outdoor

unit).

x

Check

out

the

proper

working

of

the

flow

switches

(outdoor

unit).

x

Check

out

that

the

crankcase

resistances

are

properly

supplied

and

functioning

(outdoor

unit).

x

Clean

the

metallic

filters

of

the

hydraulic

circuit.

x

Clean

the

finned

coil

by

means

of

compressed

air

or

water

jet

(outdoor

unit).

x

Check

out

that

all

the

terminals

on

the

electric

board

as

well

as

on

the

terminals

of

the

compressor

are

properly

fixed.

Clean

from

time

to

time

the

remote

control

switch’s

sliding

and

fixed

contacts

(indoor

and

outdoor

units).

x

Tightening

of

water

connections.

x

Check

out

the

tightening

and

the

balancing

of

the

fan

blades

(outdoor

unit).

x

Correct

voltage.

x

Correct

absorption.

x

Check

the

refrigerant

charge.

x

Summary of Contents for PACK DUE 12

Page 1: ......

Page 39: ...38 22 2 OUTDOOR UNITS 22 2 1 Wiring diagram of PACK DUE 9...

Page 40: ...39 22 2 2 Wiring diagram of PACK DUE 12...

Page 41: ...40 22 2 3 Wiring diagram of PACK DUE 16...

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......