2 8

S P I R I T

I T

F L O W - X

I N S T R U C T I O N M A N U A L | I M / F L O W X - E N

Flow-X

Tx+

Tx-

Rx+

External

Tx/Rx-

Tx/Rx+

Rx+

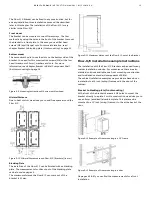

Figure 6-30 2-wire RS-485 connection

For a

2-wire RS-485

connection the Tx+ and Tx-

terminals must be connected, while the Rx+ and Rx-

terminals may remain unconnected (no need for jumpers).

Flow-X

Tx+

Tx-

Rx+

External

Rx-

Rx+

Rx+

Tx-

Tx+

Figure 6-31 4-wire RS-485 connection

RS-485

connections need terminating resistors to

reduce voltage reflections that can cause the receiver to

misread the logic level.

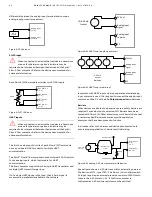

Proving signals

The connection of the prover signals depends on the Spirit

IT

Flow-X type and the prover set-up.

Flow-X/P

Ball prover / Compact prover

Connect the flow pulse signals to the corresponding modules

Connect all detector signals to

all

run modules

All applicable prove signals (except the detector signals) may

be distributed over the available modules (they only have to be

connected once):

–

prover pressure(s)

–

prover temperature(s)

–

prover densitometer

–

4-way valve commands and statuses

–

prover commands and statuses

Master meter proving based on pulses

Connect the flow pulse signals to the corresponding run

module(s) and master meter module

Connect a digital output of the “Master Meter” module to a

digital input (prove detector in) of itself and

all

run modules

Master meter proving based on totals

No connections to be made (except from the pulse inputs in

case of pulse meters)

X/P

Ball / Compact prover

Figure 6-32: Proving with a ball or compact prover on an X/P flow

computer.

Prover pressure(s)*

Prover temperature(s)*

Prover densitometer*

4-way valve commands*

Prove start command*

Plenum pressure commands*

* Connect to one of the run modules

PANEL

RUN X

RUN Y

Pu

ls

e

in

Pu

ls

e

in

Pr

ov

e

de

te

ct

or

(s

)

in

Pr

ov

e

de

te

ct

or

(s

)

in