31

drop out first followed by stages three, two and one. To achieve

maximum efficiency, stages will reignite if the system water

temperature drops below the stage Set Point minus the Set

Point Differential.

Note: Once a stage is satisfied, the blower associated with that

stage will allow a 25 second postpurge before it deactivates.

11. Once all of the stages have been satisfied, the pump will run

for the programmed post-circulate cycle (factory default 45

seconds). See Procedure for Setting Pump Delay on page 30

of the manual.

12. The control now enters the idle state. This is indicated on the

display by the "Standby" LED. The control will continue to

monitor temperature and the state of other system devices. If

the water temperature at the designated system controller

drops below the set-point value minus the switching

differential, and the thermostat circuit or tank probe circuit

closes, the control will return to step 2 and repeat the entire

operating cycle. During this idle state, if the control detects an

improper operating state for external devices such as the ECO

switch, air pressure switch, gas pressure switch, etc., the

appropriate LED(s) on the Display Board will illuminate

indicating the nature of the fault.

PREVENTATIVE MAINTENANCE

These boilers are designed to give many years of efficient and

satisfactory service when properly operated and maintained. To

assure continued good performance, the following

recommendations are made.

The area around the unit should be kept clean and free from lint

and debris. Sweeping the floor around the boiler should be done

carefully. This will reduce the dust and dirt which may enter the

burner and heat exchanger, causing improper combustion and

sooting.

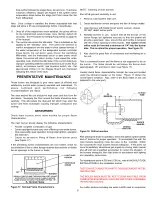

MAIN BURNERS

Check main burners every three months for proper flame

characteristics.

The main burner should display the following characteristics:

•

Provide complete combustion of gas.

•

Cause rapid ignition and carry over of flame across entire burner.

•

Give reasonably quiet operation during initial ignition, operation

and extinction.

•

Cause no excessive lifting of flame from burner ports

(see Figure 17).

If the preceding burner characteristics are not evident, check for

accumulation of lint or other foreign material that restricts or blocks

the air openings to the burner or boiler.

Figure 17. Normal Flame Characteristics

NOTE: Cleaning of main burners.

Shut off all gas and electricity to unit.

1. Remove main burners from unit.

2. Check that burner venturi and ports are free of foreign matter.

3. Clean burners with bristle brush and/or vacuum cleaner.

DO NOT distort burner ports.

4. Reinstall burners in unit. Ensure that all the screws on the

burner flange are tightened securely so that the gasket will

provide a good seal. Also, ensure that each orifice is centered

with the venturi opening of every burner.

The washer of the

orifice must be inserted a minimum of 1/4" into the burner

tube. This is critical for proper operation. See Figure 18.

5. Also check for good flow of combustion and ventilating air to

the unit.

This is a powered burner and the flame is not supposed to be on

the burner. The flame should be just above the burner deck

approximately 1/8” and blue in color (see Figure 17).

Visually check flame characteristics through the view port located

under the left-hand header on the boiler. Figure 17 shows the

normal flame condition. Also, refer to the flame label on the unit

(adjacent to the view port).

Figure 18. Orifice Insertion

After placing the boiler in operation, check the ignition system safety

shut-off devices for proper operation. To accomplish this with the

main burners operating, close the valve on the manifold. Within

four seconds the main burners should extinguish. If this does not

occur immediately, discontinue gas supply by closing main manual

shut-off and call a qualified serviceman to correct the situation. If

the burners extinguish, then light boiler in accordance with lighting

and operating instructions.

For installations above 4,500 feet (1350 m), refer to HIGH ALTITUDE

INSTALLATIONS in the installation section.

THE FLOW OF COMBUSTION AIR TO THE BOILER MUST NOT BE

OBSTRUCTED.

THE BOILER AREA MUST BE KEPT CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER FLAMMABLE

VAPORS AND LIQUIDS.

Any safety devices including low water cutoffs used in conjunction