15

CONVENTIONAL SPACE HEATING INSTALLATION

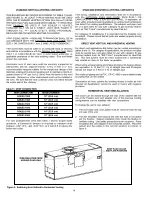

Modern fin type boilers are exceptionally fast heating units. The low

water volumes in relation to firing rates require special attention to

water flow rates for smooth, efficient operation. These

considerations for the A. O. Smith copper heat exchanger boilers

are covered below.

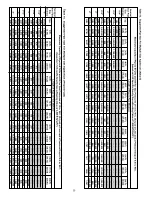

Refer to table 4 showing flow rate vs. pressure drop and temperature

rise.

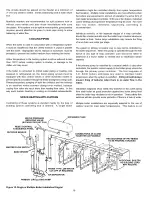

Figure 10 shows a typical installation of the boiler.

A system with several flow controlled zones, or with a 3-way mixing

valve system could present a flow rate to the boiler of less than

required for a maximum of 50°F (28°C) temperature rise. Design

system with compensating bypasses to the boiler.

A system bypass should be installed as shown in figure 10 to

prevent boiler circulation starvation when the system zones call for

reduced flow.

This bypass may also be used with multiple boilers manifolded for

reverse-return flow. The system bypass would be installed from

boiler outlet to suction side of pump.

The boiler piping system of a hot water heating boiler connected to

heating coils located in air handling units where they may be

exposed to circulating refrigerated air, must be equipped with flow

control valves or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle. It is highly recommended

that the piping be insulated.

INSTALLATION AS BOILER REPLACEMENT

Installation as boiler replacement on an old system with large water

volume may result in condensation within the boiler on cold starts.

This condensing of water vapor in the combustion area can be

prevented if a portion of the system water flow is diverted past the

boiler to cause an increase in boiler temperature rise.

BYPASS BALANCING

With systems where water temperature can be expected to drop

appreciably due to long standby periods, or heavy draw down, a

bypass pipe of at least 1" size with a balancing cock should be

installed between the boiler inlet and outlet (see figure 10). When

the system first starts, the valve should be slowly opened until the

condensing ceases. This adjustment remains at a permanent

setting to establish required temperature rise across the boiler.

AIR SEPARATOR

An air separator as shown in the piping diagram is reccommended

especially for modern commercial hydronic systems.

VENT VALVES

It is recommended that automatic, loose key or screwdriver type

vent valves be installed at each convector or radiator.

SYSTEM HEADERS

Split systems with individual supply and return lines from the boiler

room should normally have this piping connected to supply and

return manifold headers near the boiler. To achieve good water

distribution with minimum pressure drop for several circuits,

manifolds should be larger than system loops.

SYSTEM INSTALLATION

GENERAL

If the system is to be filled with water for testing or other purposes

during cold weather and before actual operation, care must be

taken to prevent a down draft entering the boiler or freezing air from

contacting the system. Failure to do so may cause the water in the

system to freeze with resulting damage to the system. Damage

due to freezing is not covered by the warranty.

Good practice requires that all piping, etc., be properly supported.

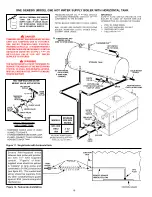

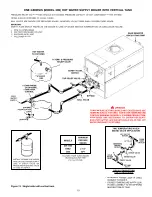

The boilers described in this manual may be used for space

(hydronic) heating or for the heating of potable water. If the heater

is to be used for hydronic space heating, follow the instructions on

pages 15-17 given for equipment required for installation as in

Figure 10. However, if units are to be used for heating potable

water, the information describing specific systems is found on

pages 17-19. See figures 11 and 13. Installations must comply

with all local codes.

HYDRONIC INSTALLATION

The following is a brief description of the equipment required for

installations noted in this manual. All installations must comply

with local codes (see figure 10).

Table 12: INSTALLATION ITEMS

NO.

SUGGESTED ITEMS FOR INSTALLATION

1.

PAIR OF SHORT PIPE NIPPLES, PAIR OF BOILER

LOOP TEES AND BALL VALVE BETWEEN SYSTEM

SUPPLY

AND RETURN - ONE SET PER EACH BOILER

2.

BOILER PIPE LOOP (See Sizing Data Table 4.)

3.

BOILER CIRCULATING PUMP (See Sizing Data Table 4.)

4.

THERMOMETER

5.

PRESSURE GAUGE

6.

LOW WATER CUTOFF (If Required By Local Code.)

7.

SAFETY FLOW SWITCH (Factory-Installed)

8.

RELIEF VALVE (Factory-Installed)

9.

BOILER INLET - OUTLET

10.

SYSTEM SUPPLY TEMPERATURE THERMOMETER

11.

DRAIN or BLOW-DOWN VALVE

WATER SUPPLY LINE

These boilers can be used ONLY in a forced circulation hot water

heating system. The pump must be interlocked with the boiler to

prevent boiler operation without water circulation. See maximum

and minimum flow rate information. Since most forced circulation

systems will be of the closed type, install the water supply line as

shown on piping diagram, figure 10.

Severe damage will occur if

the boiler is operated without proper water flow circulation.

Fast filling of large pipe, old radiator installations (where high

pressures are not available) requires bypassing of the pressure

reducing valve. Generally, pressure purging is not possible with a

well pump system. High point air venting is essential. For details,

refer to OPERATION section of this manual on page 22.

If the system is of the open type, a pressure reducing valve will not

be required as the water supply to the system will be controlled by

a manually operated valve. An overhead surge tank is required. A

MINIMUM PRESSURE OF 15 PSI (100 kPa) MUST BE MAINTAINED

ON THE BOILER AT ALL TIMES to avoid potential damage to the

boiler that may not be covered by the warranty.