15000-MNL-01 Rev A

27

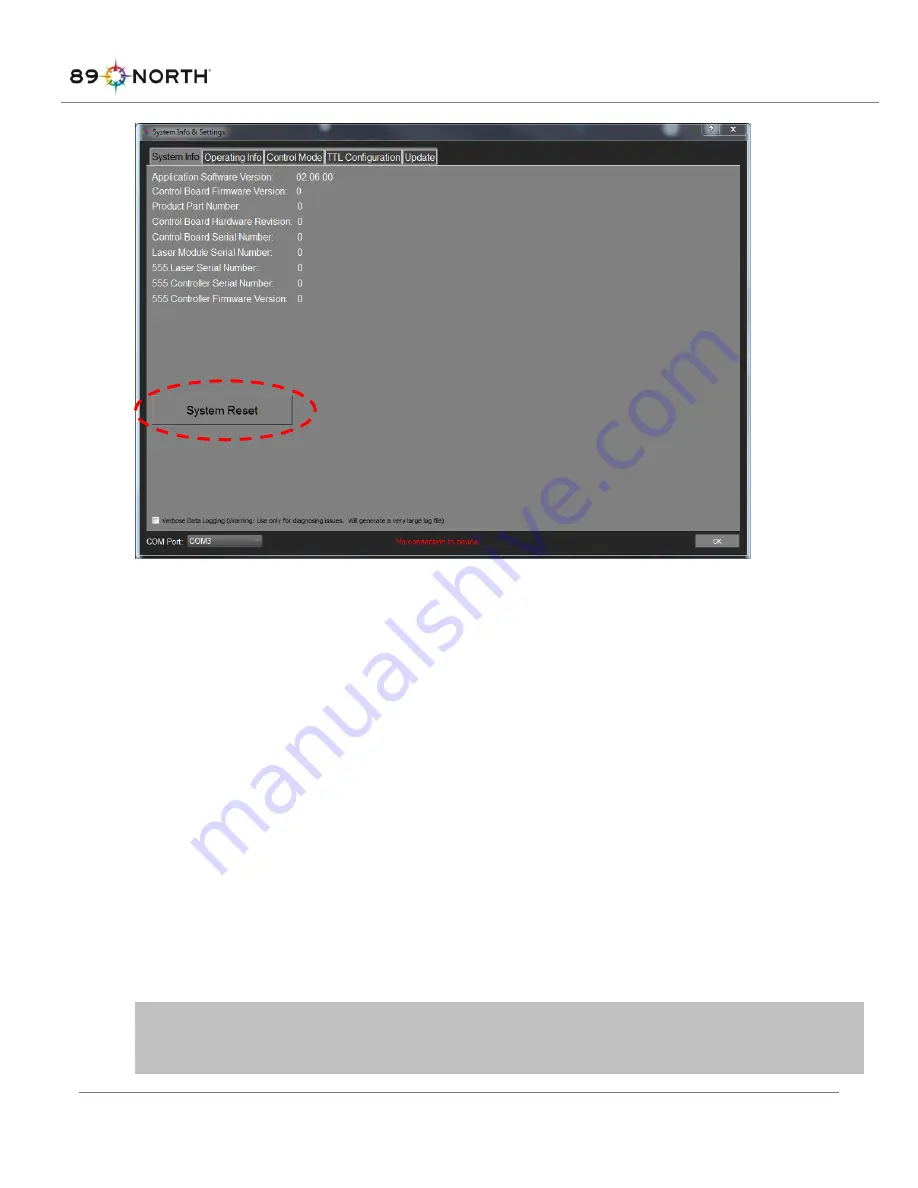

Figure 21: System Reset Button

System Status Indicators

A multi-color System Status indicator ring LED is located on the front panel soft power switch. The System

Status Indicator LED has 3 possible states in normal operation:

•

Yellow, solid: Indicates the system is in Warm-Up mode

•

Green, solid:

Indicates the system is in Idle or Run mode, ready to be operated and produce

laser emission

•

Red, solid:

Indicates the system is has a fault

Other indications are utilized for factory service modes. If the Status Indicator LED displays a color or blink

rate other than described above, contact 89 North.

See “

Laser Ready Indicators

As shown in Figure 4, the front panel of the LDI includes two Laser Ready Indicators. These indicators

illuminate blue when laser emission through the corresponding aperture can occur. Both Laser Ready

Indicators will remain extinguished while the system is in Warm Up mode since laser emission is prevented

in this mode. Once the system has completed warm up, the Laser Ready Indicator will illuminate blue for

any aperture which is capable of producing laser emission and has a fiber installed.

WARNING:

Laser Ready Indicators will illuminate blue whenever the corresponding aperture is

capable of producing laser emission.