3M 3 in. Random Orbital Buffer

2

Revision 06009

To reduce the risks associated with vibration:

• If any physical hand/wrist discomfort is experienced, work should be stopped promptly to seek medical attention. Hand, wrist and arm

injury may result from repetitive work, motion and overexposure to vibration.

To reduce the risks associated with loud noise:

• Always wear hearing protection while operating this tool. Follow your employer’s safety policy or local/national standards for personal

protective equipment requirements.

To reduce the risks associated with fire or explosion:

• Do not operate the tool in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. The abrasives are able to

create sparks when working material, resulting in the ignition of the flammable dust or fumes.

• Refer to MSDS of the material being worked as to potential for creating fire or explosion hazard.

To reduce the risks associated with hazardous dust ingestion or eye/skin exposure:

• Use appropriate respiratory, skin protection, and/or local exhaust as stated in the MSDS of the compound used and of the material

being worked on.

To reduce the risks associated with hazardous voltage:

• Do not allow this tool to come into contact with electrical power sources as the tool is not insulated against electrical shock.

To reduce the risks associated with skin abrasion, burns, cuts, or entrapment:

• Keep hands, hair, and clothing away from the rotating parts of the tool.

• Wear suitable protective gloves while operating tool.

• Do not touch the rotating parts during operation for any reason.

• Do not force tool or use excessive force when using tool.

To reduce the risk associated with whipping or hazardous pressure-rupture:

• Ensure supply hose is oil resistant and is properly rated for required working pressure.

• Do not use tools with loose or damaged air hoses or fittings.

• Be aware that incorrectly installed hoses and fittings might unexpectedly come loose at any time and create a whipping/impact hazard.

To reduce the risk associated with fly off of abrasive product or parts:

• Use care in attaching, backup pad; following the instructions to ensure that they are it is securely attached to the tool before use.

• Never over-tighten accessory fasteners.

CAUTION!

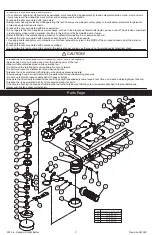

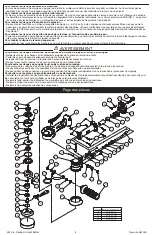

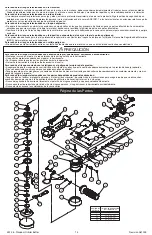

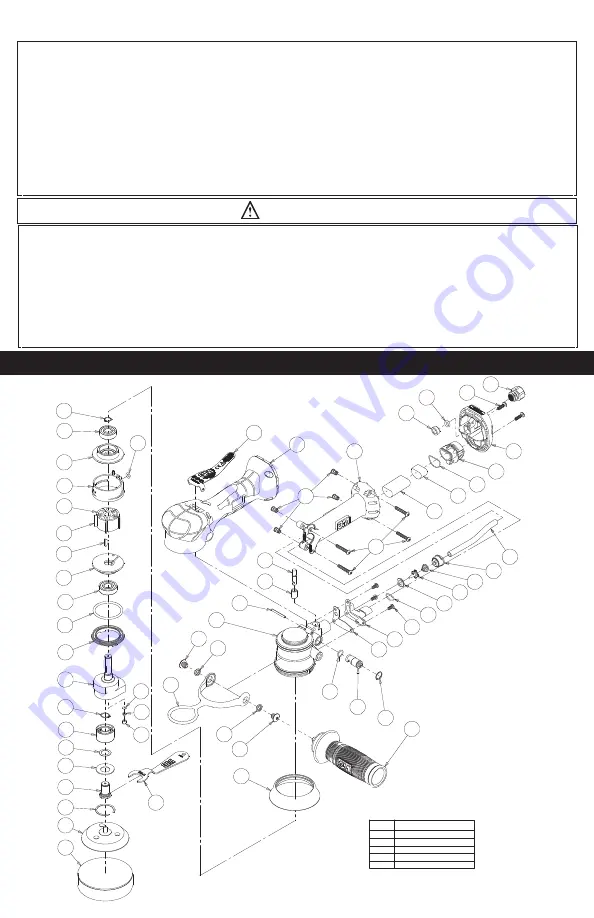

Parts Page

RAG 03/04/09

MDR 03/04/09

-RELEASE FOR PRODUCTION

A

DESCRIPTION / DATE

R

REVISION RECORD

SCREW, BUTTON HEAD TORX M4.0 X 15 mm BLACK

2

1

Y

L

B

M

E

S

S

A

G

N

I

H

S

U

B

T

E

L

N

I

T

P

N

8

1

-

4

/

1

3

1

0

0

A

P

X

0

6

1

G

N

I

R

-

O

m

m

8

7

.

1

x

m

m

6

.

7

9

0

5

0

A

P

X

8

5

59

XPA1398

Y

T

Q

N

O

I

T

P

I

R

C

S

E

D

N

/

P

T

I

1

G

N

I

R

G

N

I

N

I

A

T

E

R

L

A

N

R

E

T

X

E

0

4

0

0

A

P

X

1

1

S

D

L

E

I

H

S

2

-

G

N

I

R

A

E

B

8

X

6

2

X

0

1

1

2

0

0

A

P

X

2

1

E

T

A

L

P

D

N

E

R

A

E

R

3

3

8

1

A

P

X

3

1

G

N

I

R

-

O

m

m

0

.

2

x

m

m

5

2

4

0

0

A

P

X

4

1

Y

L

B

M

E

S

S

A

R

E

D

N

I

L

Y

C

5

7

1

2

A

P

X

5

1

R

O

T

O

R

D

E

N

I

H

C

A

M

5

0

0

0

B

P

X

6

5

E

N

A

V

0

1

0

0

A

P

X

7

1

Y

E

K

F

F

U

R

D

O

O

W

m

m

3

1

x

m

m

3

1

4

0

0

A

P

X

8

1

E

T

A

L

P

D

N

E

T

N

O

R

F

2

3

8

1

A

P

X

9

1

S

D

L

E

I

H

S

2

-

G

N

I

R

A

E

B

8

X

8

2

X

2

1

9

1

0

0

A

P

X

0

1

1

G

N

I

R

-

O

m

m

1

.

3

x

m

m

4

.

9

3

5

4

0

0

A

P

X

1

1

1

D

A

E

R

H

T

M

M

0

5

-

G

N

I

R

K

C

O

L

3

9

9

1

A

P

X

2

1

13

XPB0479 3 in. x 1/2 in. ORBIT AirSHIELD™ SHAFT BALANCER - 20.0 mm MOTOR

1

1

R

E

T

L

I

F

2

2

1

0

A

P

X

4

1

1

E

V

L

A

V

K

C

E

H

C

L

L

I

B

K

C

U

D

1

2

1

0

A

P

X

5

1

1

R

E

N

I

A

T

E

R

E

V

L

A

V

0

2

1

0

A

P

X

6

1

17

XPA0090 11.9 mm (15/32 in

1

G

N

I

R

G

N

I

N

I

A

T

E

R

).

18

XPA0938 12 x 28 x 16 DOUBLE ROW ANGULAR CONTACT BEARING - 1 SEAL

1

1

K

H

T

2

.

0

x

D

O

0

.

8

1

x

D

I

1

.

2

1

R

E

C

A

P

S

6

1

0

0

A

P

X

9

1

1

R

E

H

S

A

W

E

L

L

I

V

E

L

L

E

B

7

1

0

0

A

P

X

0

2

1

E

L

D

N

I

P

S

2

1

3

0

B

P

X

1

2

1

D

E

R

5

8

4

S

M

P

-

M

3

R

O

F

H

C

N

E

R

W

D

A

P

m

m

7

1

6

7

7

1

A

P

X

2

2

1

G

N

I

R

G

N

I

N

I

A

T

E

R

8

1

0

0

A

P

X

3

2

24

N/A

1 Back-up Pad supplied with each tool (type determined by model)

1

1

lo

o

t

h

c

a

e

h

ti

w

d

ei

lp

p

u

s

t

o

n

si

d

a

P

g

ni

ff

u

B

A

/

N

5

2

1

C

5

8

4

S

M

P

-

R

E

G

N

A

H

D

N

A

H

o

w

T

4

5

9

1

A

P

X

6

2

2

D

E

R

5

8

4

S

M

P

-

G

U

L

P

D

E

D

A

E

R

H

T

8

M

5

5

9

1

A

P

X

7

2

2

G

N

I

R

R

E

C

A

P

S

5

6

8

1

A

P

X

8

2

1

R

E

F

F

U

B

-

D

U

O

R

H

S

C

A

V

-

N

O

N

W

L

.

ni

3

8

0

5

0

B

P

X

9

2

30

XPB0390 MACHINED DIE-CAST

1

R

E

F

F

U

B

-

G

N

I

S

U

O

H

R

O

T

O

M

1

N

I

P

G

N

I

R

P

S

R

E

D

N

I

L

Y

C

4

0

0

0

A

P

X

1

3

1

E

V

E

E

L

S

E

V

L

A

V

5

1

0

0

A

P

X

2

3

1

R

E

F

F

U

B

-

Y

L

B

M

E

S

S

A

M

E

T

S

E

V

L

A

V

5

9

9

1

A

P

X

3

3

1

G

N

I

R

-

O

m

m

5

.

1

x

m

m

9

3

4

0

0

A

P

X

4

3

1

5

8

4

S

M

P

-

L

O

R

T

N

O

C

D

E

E

P

S

™

D

N

A

H

o

w

T

H

S

U

L

F

4

2

2

2

A

P

X

5

3

1

G

N

I

R

G

N

I

N

I

A

T

E

R

L

A

N

R

E

T

N

I

9

3

0

0

A

P

X

6

3

T

P

O

E

L

D

N

A

H

E

D

I

S

M

3

0

6

9

1

A

P

X

7

3

1

R

E

F

F

U

B

-

T

E

K

S

A

G

2

9

9

1

A

P

X

8

3

1

R

E

F

F

U

B

-

E

L

Z

Z

O

N

T

S

U

A

H

X

E

R

O

T

O

M

7

8

3

0

B

P

X

9

3

3

W

E

R

C

S

P

A

C

D

A

E

H

N

O

T

T

U

B

T

E

K

C

O

S

X

E

H

8

X

4

M

4

6

6

0

A

P

X

0

4

1

H

T

D

I

W

m

m

3

.

1

X

.

D

.I

m

m

0

.

1

1

,

G

N

I

R

-

O

4

1

1

2

A

P

X

1

4

1

T

A

E

S

E

V

L

A

V

9

0

0

0

A

P

X

2

4

1

E

V

L

A

V

7

0

0

0

A

P

X

3

4

1

G

N

I

R

P

S

E

V

L

A

V

4

1

0

0

A

P

X

4

4

1

Y

L

B

M

E

S

S

A

L

A

E

S

E

N

I

L

R

I

A

0

3

7

0

A

P

X

5

4

1

R

E

F

F

U

B

-

G

N

I

B

U

T

T

E

L

N

I

6

5

9

1

A

P

X

6

4

4

W

E

R

C

S

P

A

C

D

A

E

H

N

O

T

T

U

B

T

E

K

C

O

S

5

2

x

4

M

2

1

5

0

A

P

X

7

4

4

M

M

4

T

R

E

S

N

I

D

E

D

A

E

R

H

T

1

7

0

0

A

P

X

8

4

1

R

E

F

F

U

B

-

E

L

D

N

A

H

5

2

3

0

C

P

X

9

4

1

R

E

F

F

U

B

-

P

I

R

G

E

L

I

T

P

E

R

G

7

6

0

0

D

P

X

0

5

51

XPA2079 3M ROB 11,000 RPM 12.0 mm (1/2 in.) ORBIT THROTTLE LEVER

1

1

)

s

e

ni

h

c

a

M

M

P

R

0

0

0

,

0

1

r

o

f(

T

R

E

S

N

I

R

E

L

F

F

U

M

3

4

0

2

A

P

X

2

5

1

R

E

F

F

U

B

-

R

E

L

F

F

U

M

4

7

1

2

A

P

X

3

5

1

H

T

D

I

W

m

m

0

.

1

X

.

D

.I

m

m

0

.

9

1

,

G

N

I

R

-

O

1

8

0

2

A

P

X

4

5

1

R

E

F

F

U

B

,

P

A

C

T

S

U

A

H

X

E

5

4

4

0

B

P

X

5

5

1

D

E

R

5

8

4

S

M

P

-

P

A

C

D

N

E

T

S

U

A

H

X

E

/

T

E

L

N

I

2

5

9

1

A

P

X

6

5

1

G

N

I

R

E

V

I

T

P

A

C

T

E

L

N

I

0

1

5

0

A

P

X

7

5

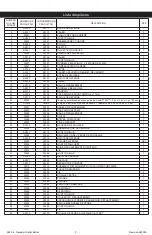

ITEM NO. TORQUE SETTINGS in.-lbs (N-m)

12

55 - 65 (6.2 - 7.3)

40

21 - 30 (2.4 - 3.4)

47

20 - 25 (2.2 - 2.8)

59

27 - 30 (3.0 - 3.4)

60

60 - 72 (6.8 - 8.1)

40

41

42

43

44

46

45

56

22

1

2

3

5

4

7

6

8

9

10

11

12

13

14

15

16

17

18

19

38

20

39

48

21

23

25

24

51

33

32

50

53

54

55

59

60

58

57

49

30

31

27

28

26

28

27

37

29

34

35

36

47

52

PERMISSION OF X'POLE PRECISION TOOLS INC. IS PROHIBITED.

DRWN BY / DATE

MATERIAL

PROPRIETARY AND CONFIDENTIAL

PROPERTY OF X'POLE PRECISION TOOLS INC. ANY REPRO-

STD TOL

0.1

PRECISION

X'POLE

0.5°

XX/XX +/-

TOOLS INC.

RAG

03/04/09

.XX +/-

DUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN

03/04/09

SEE BOM

ENG APP / DATE

ANGLES +/-

CKD BY / DATE

0.05

NA

NA

MDR

XPC0332

P/N

TITLE

.X +/-

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE

.XXX +/-

3M 3 in. (77 mm) x 1/2 in. (12 mm) ORBIT, 11,000

RPM RANDOM ORBITAL BUFFER PARTS PAGE