Page

5

of

44

3DGence Material Management System | version 1 | 03.2022

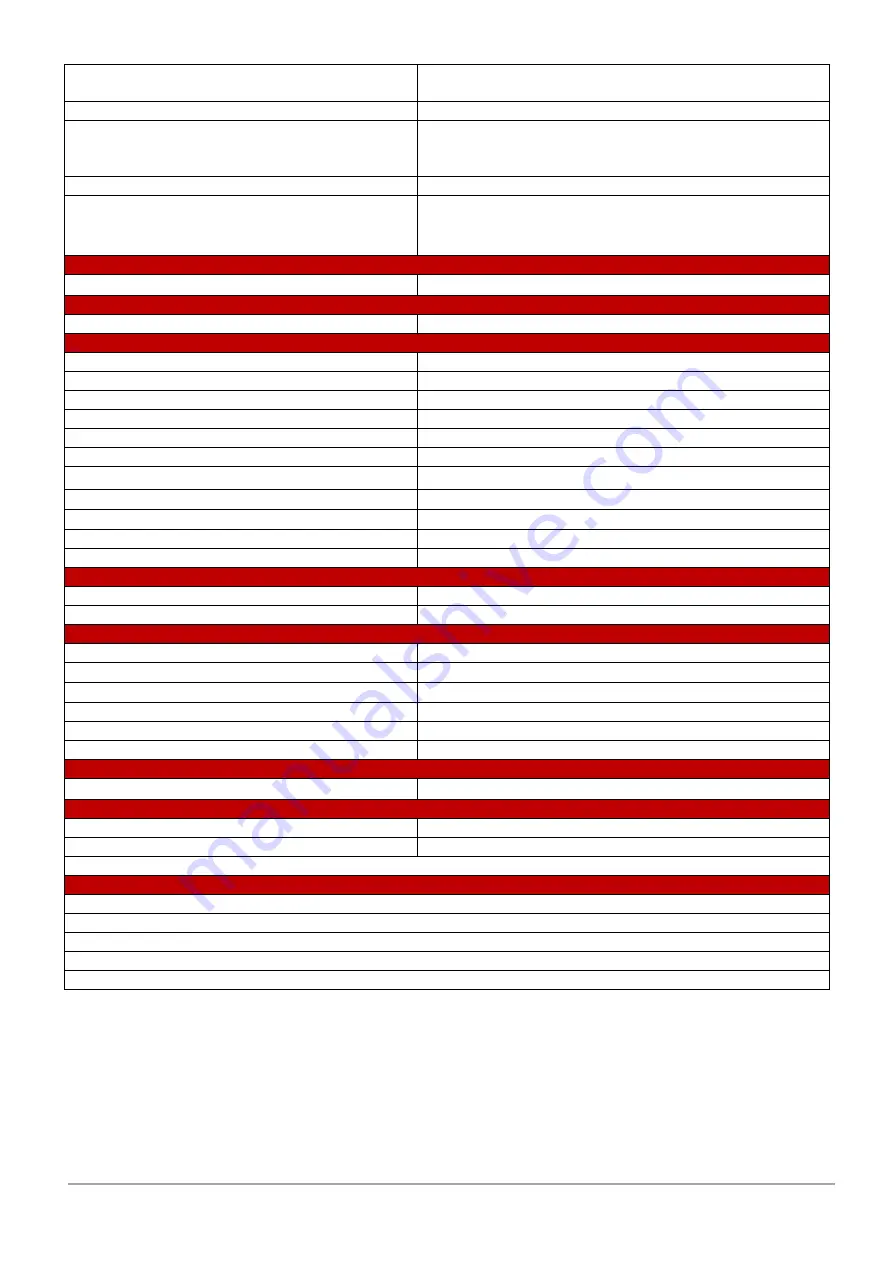

- 3 chambers: Plug NEMA L6 20A

- 6 chambers: 2x Plug NEMA L6 20A

Length of power supply cable

2200 mm

Voltage

- 1 chamber: 230V AC (210-250V AC)

- 3 chambers: 230V AC (210-250V AC)

- 6 chambers: 2x 230V AC (210-250V AC)

Frequency

50-60 Hz

Maximum power consumption of the device without

additional accessories

- 1 chamber: 1300 W

- 3 chambers: 3680 W

- 6 chambers: 7300 W

TEMPERATURES

Operating temperature range

50°C

-

200°C

CONNECTIVITY

Communication

Wi-Fi, LAN, USB

TECHNOLOGY

Working technology

Dry air (actively dried)

Device chamber space (W x D x H)

470 mm x 260 mm x 320 mm

Volume of chamber of the device

39.1 L

Number of places for materials in one chamber

4 (unlimited with CUSTOM option)

Number of chambers in the device

Depending on version (1, 3 or 6 chambers)

Maximum diameter of the filament spool

220 mm

Maximum spool thickness

90 mm

Material tracking system

Smart Material Manager

Third-party materials

Yes, in the CUSTOM option

Process settings for material preparation

Preset / Edit in CUSTOM option

Recrystallisation process settings

Pre-defined

SOFTWARE

Device monitoring and archive

Locally and in the 3DGence CLOUD

Software updates

Automatic, via USB

STRUCTURE

Structure

Freestanding, equipped with castors

Frame

Steel

Door

Sealed / thermally insulated with active ventilation

Electronics

Original 3DGence

NFC TAG reader

Yes, on the front of the device

Display

10'' TFT capacitive with 1280 x 768 px resolution

SECURITY

Door

Mechanical lock with key, door opening sensor

CERTIFICATION

Compliance with standards

TBD

Designations

TBD

EU certification of the device

ACCESSORIES

Recrystallisation set for prints

Desiccant cartridges (one for each chamber)

Drawers for storing materials in the device chamber (one for each chamber)

Wi-Fi adapter

Power adapter 1x 3ph 400V 32A / 3x 1ph 230V 32A (for connecting additional 3 chambers)

3.

DEVICE IDENTIFICATION

The MMS device can be identified by its serial number which can be found on the nameplate located on the rear cover of the

device. You can also check the serial number on the printer display. By submitting a request via the 3DGence CLOUD platform,