3D Systems, Inc.

30

p/n: 15-D99, rev. C

6.3 Inert Gas Requirements

A customer supplied argon system must be in place

before

the DMP Flex 350 is installed.

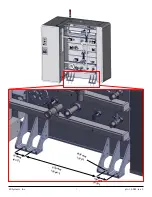

When installing the argon supply line:

• The supply line must reach the DMP 6m.

• Route argon supply line through the ceiling.

• Locate the drop over the control panel.

• The minimum internal diameter of the argon supply line is 14 mm.

The connection for the argon supply is located on the back of the electrical cabinet.

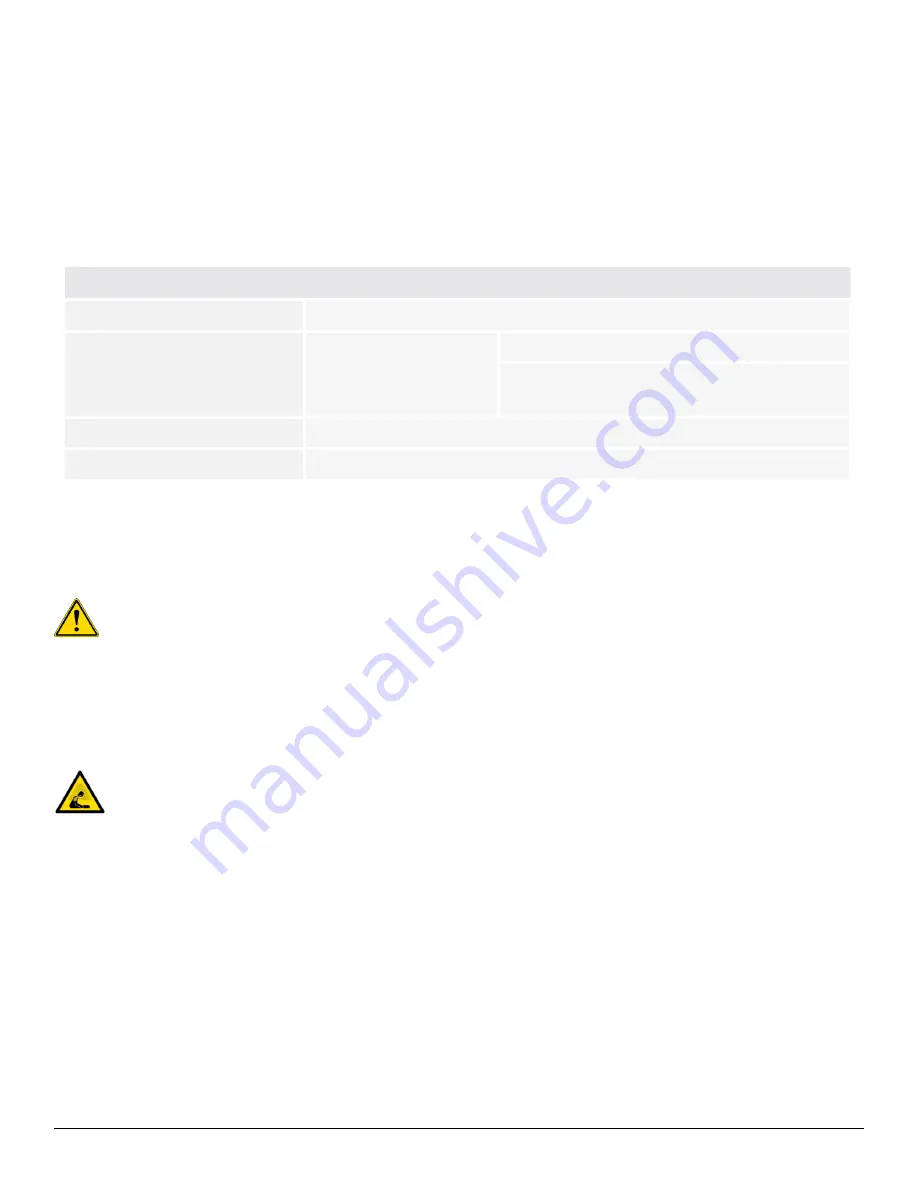

ARGON GAS

DMP SYSTEM

Connection type

Rc 1/2” BSPP female thread with hose barb 13mm added.

Supply rate

200 liters / minute

Preparation cycle requires 4500 liter (1200 gal)

Job execution requires 0 - 50 liter/hour

(0-13 gal/hour)

Supply Pressure

Minimum 4 bar (58 psi) - Maximum 6 bar (87 psi)

Quality

4.8 or better

For an argon supply, you may use a bulk (liquid) argon tank or argon cylinders. The quality must be 4.8 or better.

If a liquid argon supply is used, the supply tubing from the argon source to the machine must be at least 20 meters (65.6 feet)

long. This distance will act as a buffer and will make certain the temperature of the argon is not below freezing when it enters

the machine.

Caution: Allowing argon that is below 0 degrees C (32 F) to enter the DMP Flex 350 will damage the machine

If using argon cylinders, the following is recommended:

• Use one pack of twelve cylinders connected with an auto-switching manifold.

•

A high volume flow pressure reducer must be used for the cylinders. This allows the chamber to fill quicker.

•

Use two particle filters immediately after the reducer. One 5μm filter and one 0.01μm filter, (both are customer

supplied).

WARNING: INERT GAS (ARGON), POSES AN ASPHYXIATION HAZARD. ARGON IS HEAVIER THAN AIR AND WILL

“POOL” ON THE FLOOR AND IN ANY LOW POINTS

The printer, its print processes, and the materials intended for use with the printer are designed for operation with a chamber

of argon gas as the inert gas. Argon is a true inert gas that does not react with any metal material during printing, thus

providing a safe and stable processing environment. All certifications, material datasheets, process parameters, etc. for all

materials are developed with argon as the inert gas.

Any use of an inert gas other than argon, such as nitrogen for example, is at the user’s own risk, and 3D Systems shall not be

responsible in any way for the performance, safety, or part quality when a printer is used with an inert gas other than argon. If

an inert gas other than argon is used, it is the user’s responsibility to ensure the combination of metal material and inert gas is

safe because some materials, for example titanium or aluminum, are reactive with some inert gases, such as nitrogen.