3D Systems, Inc.

7

p/n: 15-D99, rev. C

3.5 DMP Flex 350 Printer (process chamber & electrical cabinet)

Supplied by: 3D Systems

Installed by: 3D Systems

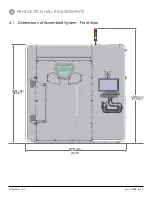

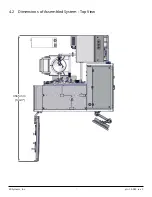

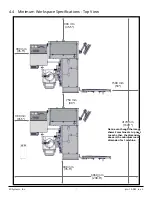

A. Physical dimensions

• Weight:

3940 kg (8686 lbs)

• Dimensions (W x D x H):

2370 x 1775 x 2670 mm (93.3 x 69.9 x 105.12 in)

• Capable of operating at altitudes up to 2000 m (6562 ft) above sea level.

• Optional counterweight:

450 kg (992 lbs)

B. Electrical - connected to facility power

• 400 VAC, 50/60 Hz

Caution: Even in case of very short (<20ms) mains voltage interruptions, the main power switch on the DMP

Flex 350 will trip and manual action will be needed to restart the system. If continuous operation is required,

an uninterrupted power supply (UPS) should be used.

• Full load current: 16 A

• Circuit protection: 32 A

• 3 phase + N + GND electrical cable.

To be supplied by customer (see §4.10 for specs)

• Max power consumption: 5 kW

• SCCR (short circuit current rating): 7.5 kA

C. Argon gas

• Supply pressure: 4 to 6 bar (58 to 87 psi)

• Quality: 4.8 or better

• Connection: Rc 1/2” BSPP female thread with hose barb 13mm added.

• Line from argon supply to DMP Flex 350: supplied by

customer.

• The minimum internal diameter of the argon supply

line: Ø 14 mm

• Consumption:

• Preparation cycle: 4500 liter (1200 gal.)

• Job execution: 0-50 liter/hour (0-13 gal/h)

D. Compressed air

• Supply pressure: 6 to 10 bar (87 to 145 psi).

• Oil free, quality class 1 according to ISO 8573-1:2010

• Connection: Rc 3/8” BSPP female thread with plug-in

connection 8 mm (5/16”) added

• Lines from compressed air supply to control panel:

supplied by customer

• Consumption: 50 l / min during printing

E. Cooling water

• Supplied from chiller

• Connections: G1/2” female BSP thread with hose barb

13mm added; 2 connections (In and Out)

• Flexible hoses from chiller to control panel: 25 meters

supplied by 3D Systems

F. Network connection

• Network cable: CAT6, provided by 3D Systems (20 m long)