3D Systems, Inc.

29

p/n: 15-D99, rev. C

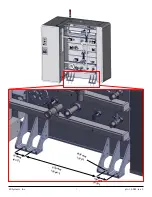

Frame ground

Main power

panel

Power sub-

panels

DMP Factory

350 blower and

vacuum pump

Chiller

Wet separator

vacuum cleaner

6.1.2 Room Air Exhaust

The facility must have a separate system for exhausting the air from the room. The system must exhaust the room air directly

to the outside. For the exhaust system, 3D Systems recommends the use of TEFC (Totally Enclosed Fan-Cooled) motors for this

application.

Fine metal particle accumulation should be avoided. Particle accumulation can lead to auto-ignition fire. Particular attention

must be made in order to avoid powder accumulation in the ventilation system.

WARNING: FAILURE TO EXHAUST THE ROOM AIR DIRECTLY TO THE OUTSIDE WILL PUT PERSONNEL AT RISK

FOR BREATHING AIR CONTAMINATED WITH METAL PARTICLES AND WILL PUT THE FACILITY AT RISK FOR AUTO-

IGNITING FIRES.

WARNING: IF YOU ARE USING REACTIVE METALS, (TITANIUM OR ALUMINUM) AIR EXTRACTION EQUIPMENT

SHOULD NOT CONTAIN FILTERS. FINE METAL PARTICLES WILL BE COLLECTED BY THE FILTER AND WILL BE A

SOURCE OF AUTO-IGNITING FIRES.

6.2 Electrical Requirements

6.2.1 Factory Connection

This task must be performed by a qualified electrician. The DMP Flex 350 production printer is designed to be run from 400

VAC 3-phase, 50/60 Hz, 9 kVA power. The facility’s power circuit must have a 50A branch protective circuit breaker or fused

disconnect with lockout/tagout capabilities. Use a 30 amp breaker for the 400 VAC supply.

It is the customers responsibility to ensure that the facility and equipment within are protected against lightning strikes

according to local regulations.

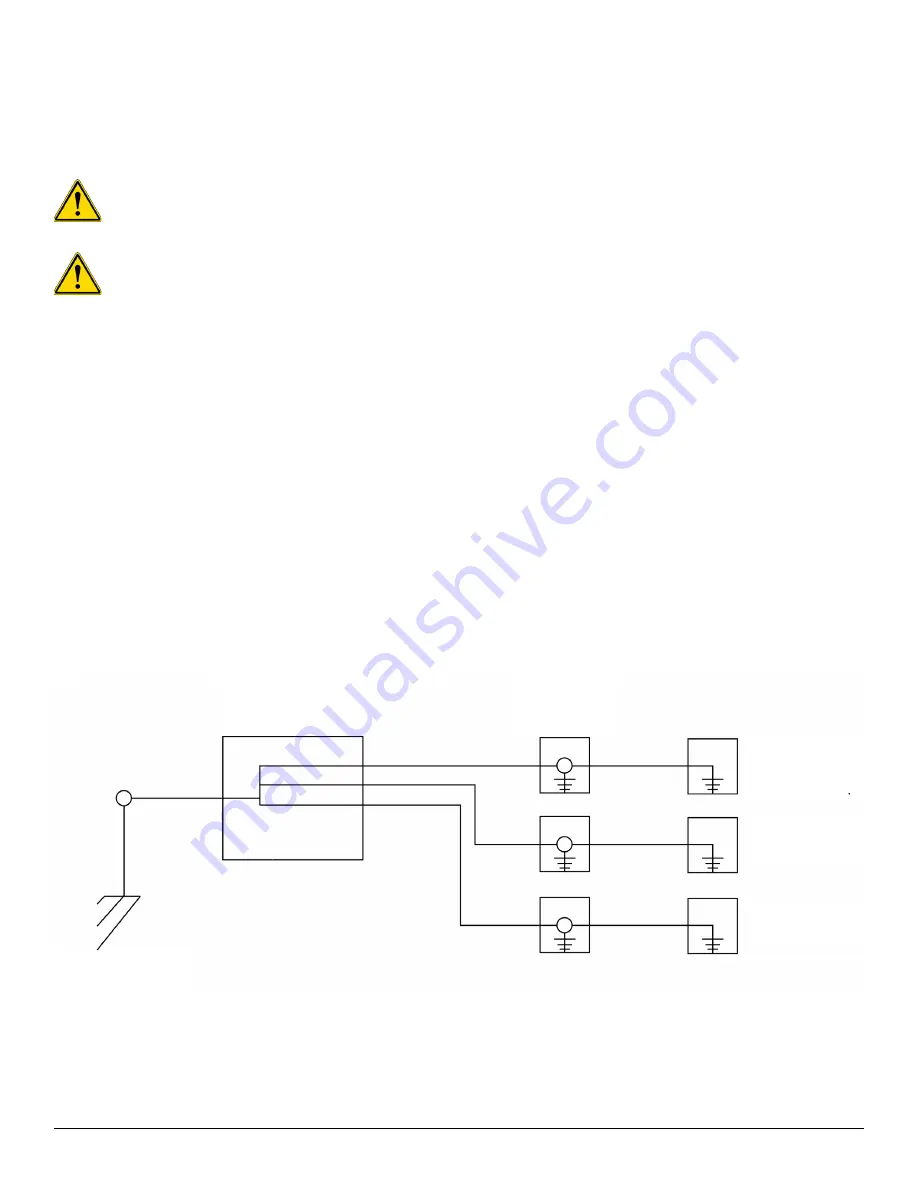

6.2.2 Customer Grounding Requirements

It is the customer’s responsibility to make sure all connections between powered equipment and the power panel are grounded

as in the diagram below.

All equipment must be grounded to prevent accumulation of static electricity.