7

HEAT PUMP OPERATION

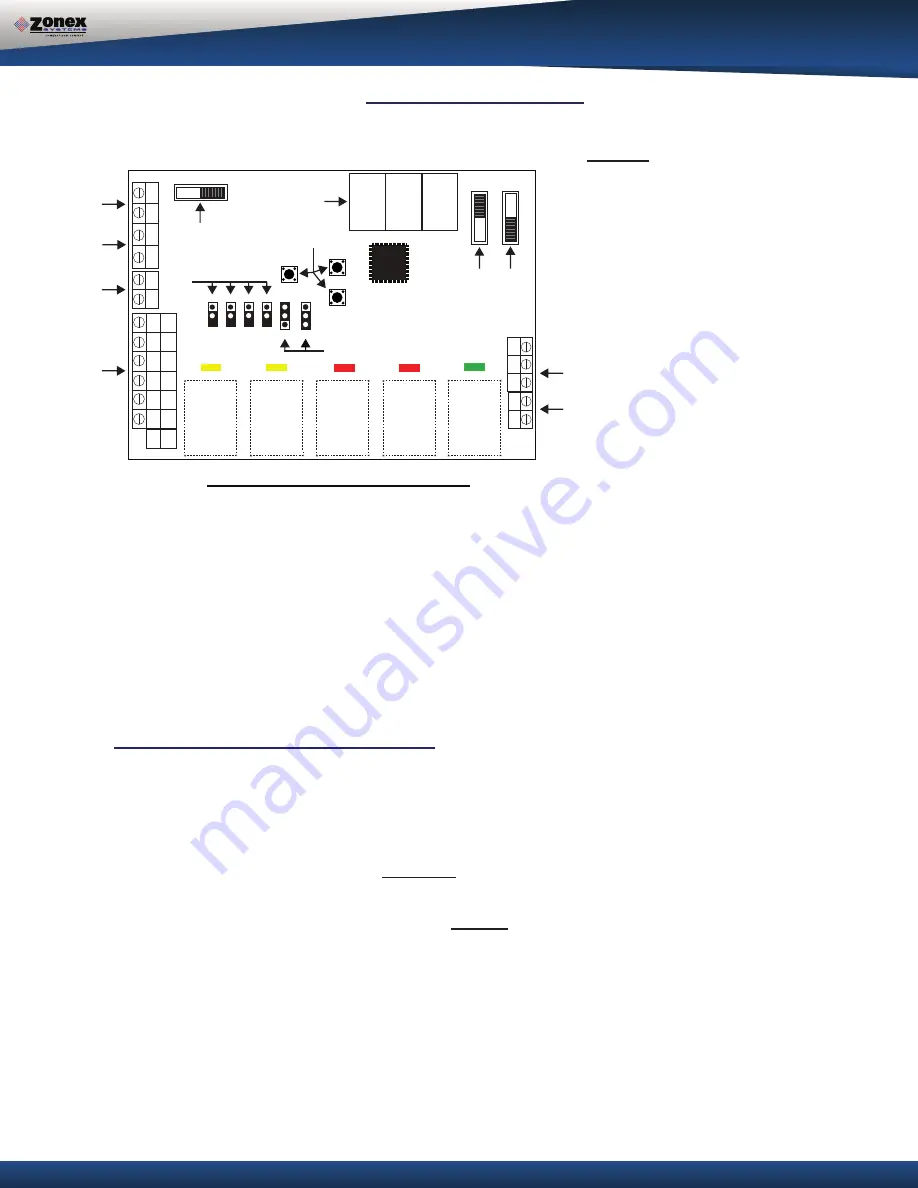

LEGEND

A

B

TR1 & TR2 24-Volt Transformer

C

Not Used

D

Unit Terminals

E

On / Off Switch

F

Priority Jumper

(Not used)

H/P Jumper

(Jump for Heat Pump

Operation)

O/B Jumper

(Heat Pump Only –

Reversing Valve Operation)

EH Jumper

(Set Up Fan Operation for

Electric Heat)

G

Digital Display (Leaving Air Temperature

and configuration)

H

Up / Down / Set Buttons (High Limit,

Low Limit, Set)

I

Fan Jumper

(Continuous or Auto)

Staging Strategy

(Time / Temperature or

Time Only)

J

Not Used

K

Not Used

L

A / B / GND Communications Wire

M

S S Terminals – Leaving Air Sensor

(LAT)

General Installation Instructions

GEN II-R Controller

1. Install the

GEN II-R

controller on an interior wall where the ambient temperature is between 32°-

120°F (0°- 48°C) non-condensing. This controller is to be installed in an accessible interior

area; not in attics or above ceilings.

2. The controller is to be powered by a

dedicated

24vac 40va transformer.

VA based on damper

style and quantity

. The transformer secondary is wired to

TR1 TR2

on the controller

(B).

The secondary voltage to the controller must be 24 to 28vac.

3. Install the LAT air sensor in the supply air between the indoor coil and electric strip heat

elements.

The LAT sensor leads may be extended using standard 18/2 thermostat wire.

4. The leaving air sensor (LAT) is calibrated to the controller at the factory. However, the

calibration should be checked as part of the system setup procedures. If adjustments are

required, use the Blue potentiometer labeled R44 located in the upper left hand corner of the

GEN II-R

controller. Screw the pot clockwise to lower the display temperature and counter -

clockwise to raise the temperature.

NOTE

: The display will update every 10 seconds.

HEAT PUMP OPERATION

TR1 & TR2 Power out to Dampers R & C

(18 ga thermostat wire)

TERMINAL FUNCTIONS / CONNECTIONS

S S – Leaving / Supply Air Sensor Input

G – Fan Output

W2 – Auxiliary / Emergency Heat

O/B – Reversing Valve Output

Y2 – Stage 2 Cool Output

Y1 – Stage 1 Cool Output

R – 24vac from Unit Transformer

TC / TC – Not Used

TR1 / TR2 – 24vac Power Input / Common

A / B - Data Transmit / Receive

5. Confirm you have daisy chained the

A

and

B

communication wires and

R

and

C

from the

Damper control boards to the GEN II-R controller (

A & L

),

A

=(TR1, TR2),

L

=(A, B). (Communi-

cation wire maximum is 4,000 ft. from the GEN II-R controller to the farthest damper).

6. On each damper board place the HP jumper on both pins for Heat Pump operation.

7. Connect the output wires from the controller to the HVAC system using standard 18 GA

thermostat wire.

GEN II-R

The

GEN II-R

is a residential / light commercial zone control system controlling 2-10 independent

zones per unit. The

GEN II-R

controller is designed for auto changeover, multi-stage Heat Pump

(2C/3H) and Gas Electric (2C/2H) applications.

The

GEN II-R

system uses field supplied programmable thermostats, which power and control the

24-volt, power open / power closed or power closed / spring open round and rectangular dampers.

Additional features include LED status indication of all system functions, digital LAT display, fully

adjustable capacity control with on-board limit settings, and optional staging strategies.

The system provides the installing contractor with a simple startup diagnostic to minimize wiring errors

and speed installation.

7 2

SET

DN

UP

S

S

GND

B

ON

AUTO

TIME/TMP

TIME

EH

O/B

HP

PRI

NIGHT

DA

Y

UNLOCK LOCK

OFF ON

G

W2

W1

Y2

Y1

TC

TC

TR1

TR2

TR1

TR2

Y1

Y2

W1

W2

G

R

HP

GE

O/B

R

Y1

Y2

G

W2

A

A

B

C

D

E

F

G

H

I

J

K

L

M

OUT

IN

TR1 / TR2 - Damper Power Daisy Chain

Damper to Damper (18GA Thermostat wire)