《目次》 《索引》

TI 71M01D03-03

1st Edition : 2007.03.12-00

STEP 5-1.

Return to home position commanded by PLC

See also “6.11 Homing Using the PLC” in the TI

In STEP 5-1, it is guided how to return to home position using Z-pulse output

from <CN4> controller interface.

In this case, it is NOT necessary to connect proximity sensor to drive.

5-1.1 Generating Z-pulse and pulse interval

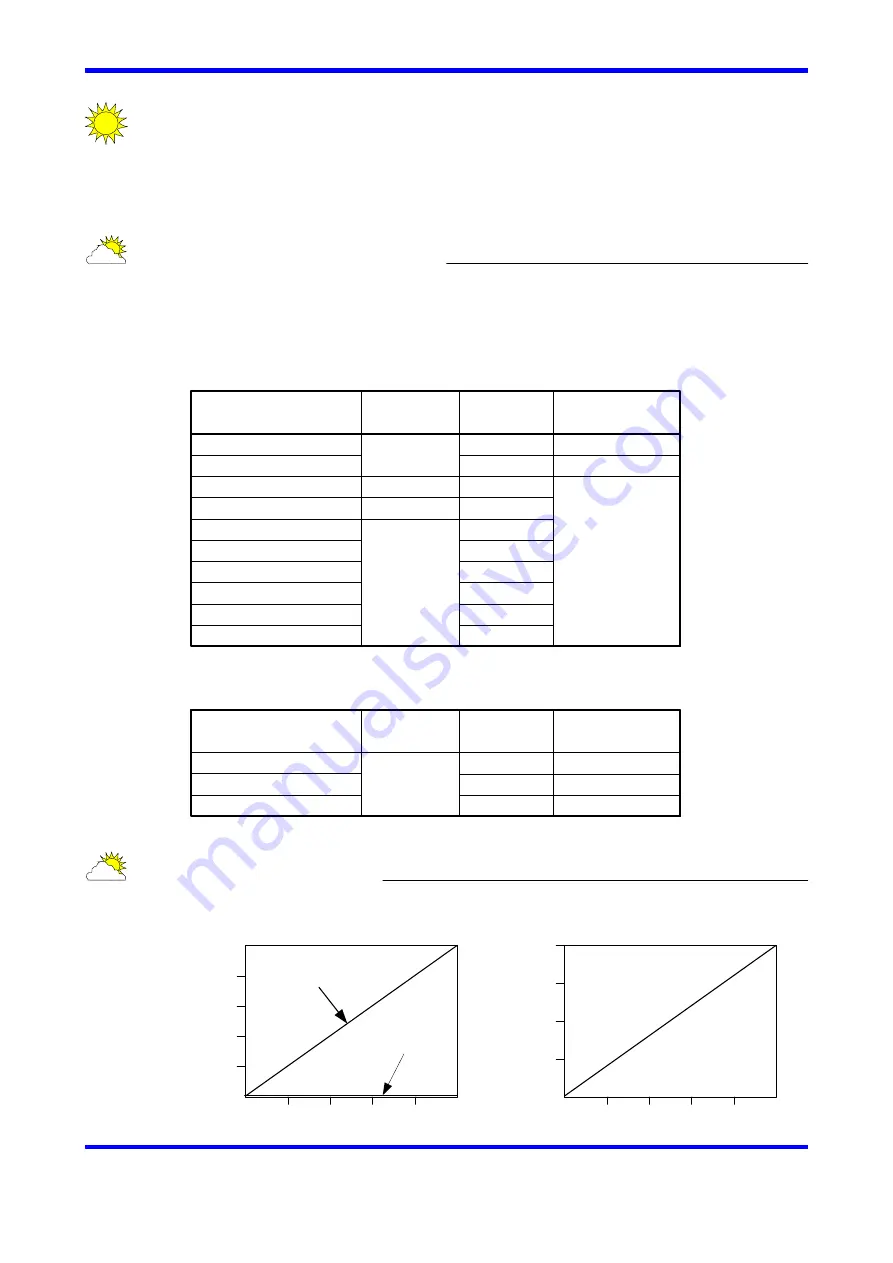

Generating method of Z-pulse and pulse interval depend on drive.

There are 2 methods for generating Z-pulse as below.

・Hardware: Z-pulse generated by optical encoder

・Software: Z-pulse generated by position signal processing by drive

Models

UD1A-□□□

UD1B-□□□

UR1A-□□□

UR1B-□□□

UR1E-□□□

UR5B-□□□

UR5E-□□□

Z-pulse

generated by

Hardware

Software

Z-pulse

ON duty

Approx. 10%

*1: excl. UD1B-004、UD1B-006

UD1C-□□□

Software

UR5C-□□□

Approx. 50%

UD1B-004/UD1B-006

(*1)

# Z-pluses

[1/rev]

100

60

200

124

150

68

78

124

52

124

Software

Approx. 12%

5-1.2 Accuracy of Z-pulse depending on velocity

Accuracy of Z-pulse depends on velocity of motor. (see below figures)

Drive resolution

0.05[μm]

0.25[μm]

Z-pulse

interval

40960

8192

Z-pulse

ON duty

4096 - 16384

819 - 3276

0.5 [μm]

8192

819 - 3276

Z-pulse

generated by

Software

DYNASERV

LINEARSERV

0

0.01

0.02

0.03

0.04

0.05

10

15

20

25

5

0

ZE

RO

si

gna

l

ac

cur

acy

[arc-

sec]

Motor velocity

[rps]

In case of

hardware ZERO

In case of

software ZERO

DYNASERV

LINEARSERV

0

0.01

0.02

0.03

0.04

0.05

10

15

20

5

0

[μm]

Motor velocity

[m/s]

5-1

ZE

RO

si

gna

l

ac

cur

acy