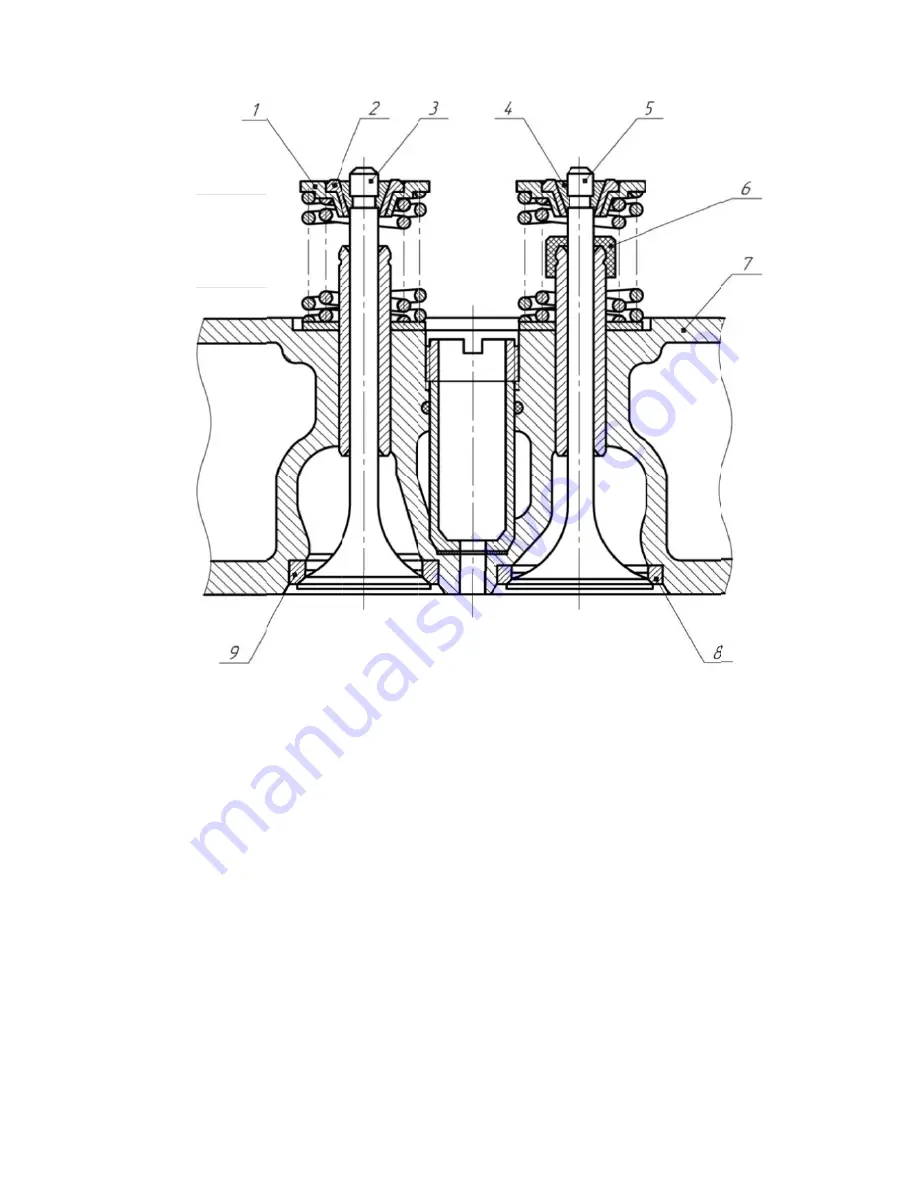

Picture 4.2 – Cylinder head with manifolds

1 – spring cap 236-1007024-V; 2 – cap liner 236-1007026-

Б; 3 – eduction valve 236-

1007015-

В4; 4 – valve cotter 236-1007028-А; 5 – induction valve

236-1007010-V; 6 – assembled collar of the induction valve 236-1007262; 7 – assembled

cylinder hear 238-1003013-D3; 8 – seat of the induction valve 236-1003108-

Б; 9 – seat of

the eduction valve 236-1003110-

В4

4.2.5 Quality of the valves and seats grinding should be checked for sealing pouring

the diesel fuel oil alternatively in the eduction and induction passages of the head with

installed and fastened valves and holding during 1 min. Leakage of the diesel fuel oil through

the valve joints with the seats is not permitted.

4.2.6 Before the installation in the guide bushings valve rods 3 and 5 should be

lubricated with the oil used in the engine lubrication system.

Содержание ???-236

Страница 25: ...26...

Страница 26: ...27 2...

Страница 40: ......

Страница 41: ......

Страница 53: ......

Страница 56: ......

Страница 59: ......

Страница 64: ...236 238 1003014 3 236 238 1003014 4 236 238 1003014...

Страница 65: ......

Страница 70: ......

Страница 73: ......

Страница 81: ......

Страница 85: ......

Страница 92: ......

Страница 95: ......

Страница 101: ......

Страница 113: ......

Страница 119: ......

Страница 122: ......

Страница 125: ......

Страница 128: ......

Страница 142: ......

Страница 144: ......

Страница 150: ......

Страница 155: ......

Страница 158: ......

Страница 160: ......

Страница 165: ......

Страница 178: ...4 A induction manifold Thread stripping no more than one thread 10 6 20 1 5 6 To reject To calibrate the thread...

Страница 193: ...N u M a r Method defect detection and Dimension and parameter mm...

Страница 201: ...4 Thread stripping M16 1 5 6H no more than two threads Inspection To calibrate the thread...