Picture is on the next page

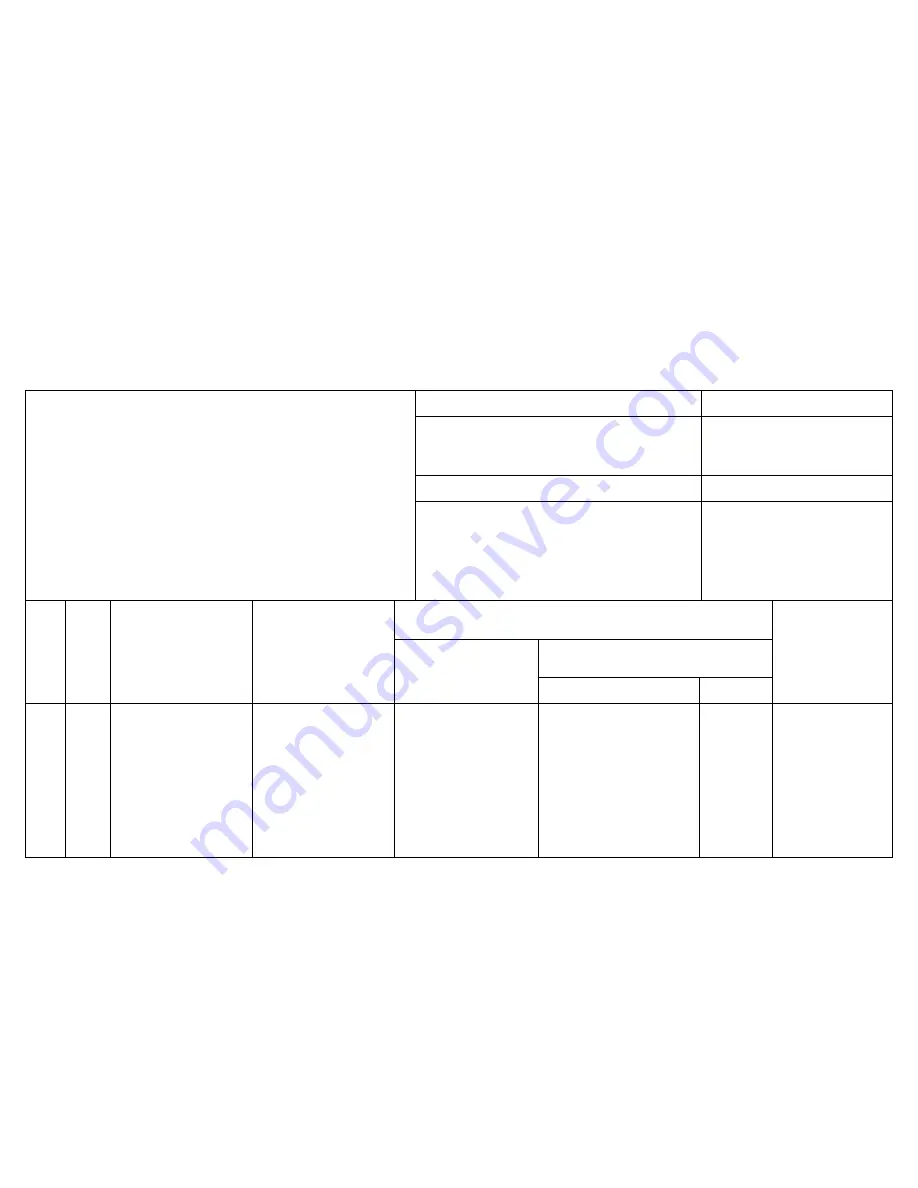

Name of the part or assembly unit

Marking

Assembled flywheel

236-1005115-

Л

238-1005115-

Л

Material

Hardness

236-1005120-

Л/238-1005120-Л- cast iron СЧ24

236-1005125-

В2-tooth rim - steel 45

179...241НВ;

167...212НВ of the main material

40...50HRC of the rims

N

um

be

r

of

t

he

d

ef

ect

L

oc

at

ion o

f

the

pi

ct

ur

e

Possible defect

Method

defect detection and means

of control

Dimension and parameter, mm

Conclusion

nominal

maximum allowable

without repair

for repair

1

2

-

К

Cracks and breaks on the

flywheel

Wear, grooves and scuffs on

the surface under the clutch

driven disk

Inspection.

Magnifier ЛП-1-4х

Inspection.

-

Dimension Ж

78±0.1

-

-

-

-

-

-

To reject

To process to the

elimination of the defect

with the following

processing of the surface

E for the depth

no more

than 3 mm

Содержание ???-236

Страница 25: ...26...

Страница 26: ...27 2...

Страница 40: ......

Страница 41: ......

Страница 53: ......

Страница 56: ......

Страница 59: ......

Страница 64: ...236 238 1003014 3 236 238 1003014 4 236 238 1003014...

Страница 65: ......

Страница 70: ......

Страница 73: ......

Страница 81: ......

Страница 85: ......

Страница 92: ......

Страница 95: ......

Страница 101: ......

Страница 113: ......

Страница 119: ......

Страница 122: ......

Страница 125: ......

Страница 128: ......

Страница 142: ......

Страница 144: ......

Страница 150: ......

Страница 155: ......

Страница 158: ......

Страница 160: ......

Страница 165: ......

Страница 178: ...4 A induction manifold Thread stripping no more than one thread 10 6 20 1 5 6 To reject To calibrate the thread...

Страница 193: ...N u M a r Method defect detection and Dimension and parameter mm...

Страница 201: ...4 Thread stripping M16 1 5 6H no more than two threads Inspection To calibrate the thread...